Low pressure non-runner glue injection device

A technology of glue injection device and no runner, applied in the field of low-pressure glue injection device without runner, can solve the problems of manual removal, affect product quality, increase waiting time, etc., so as to reduce waste of glue material, save production time, and speed up molding effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

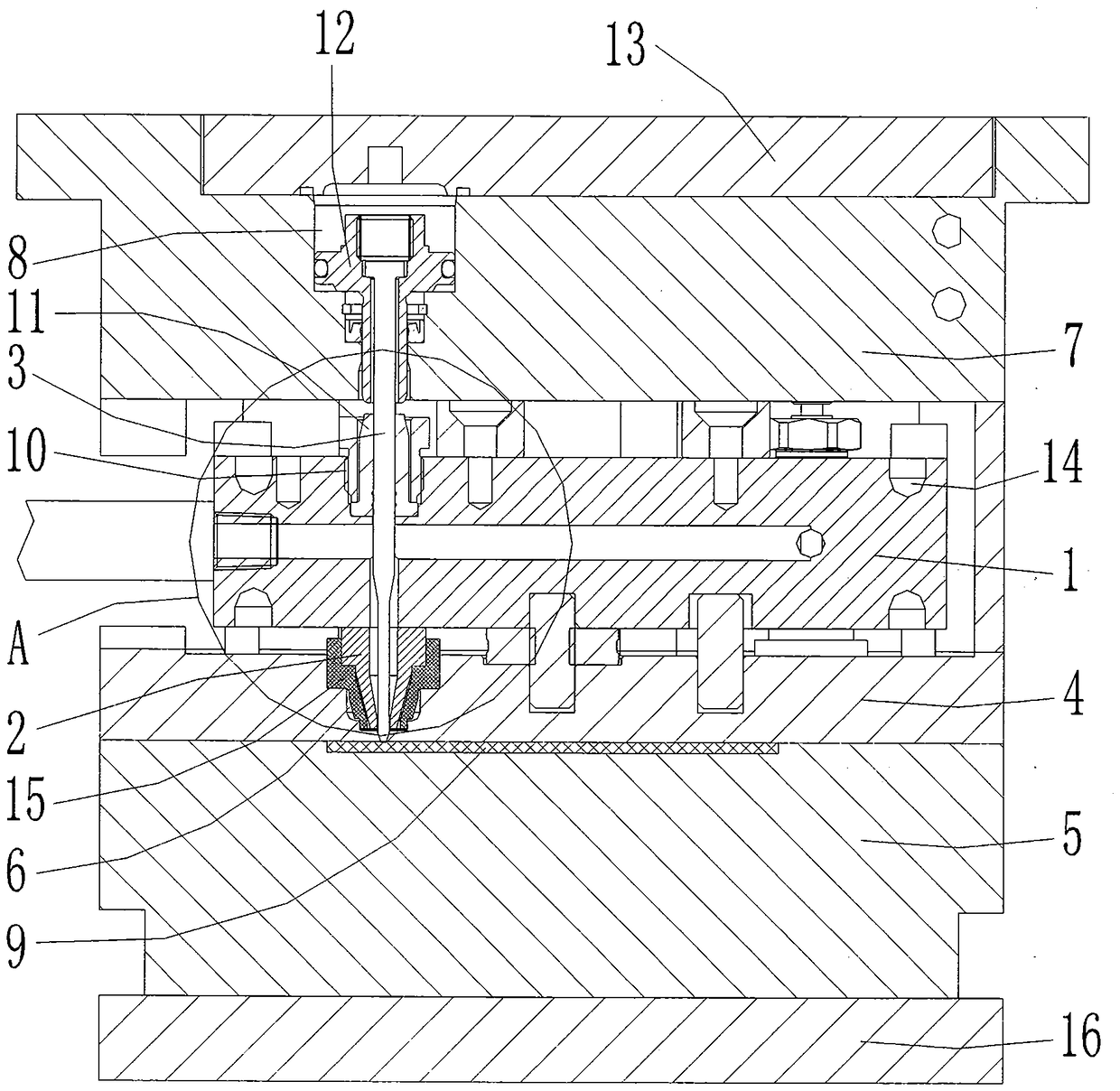

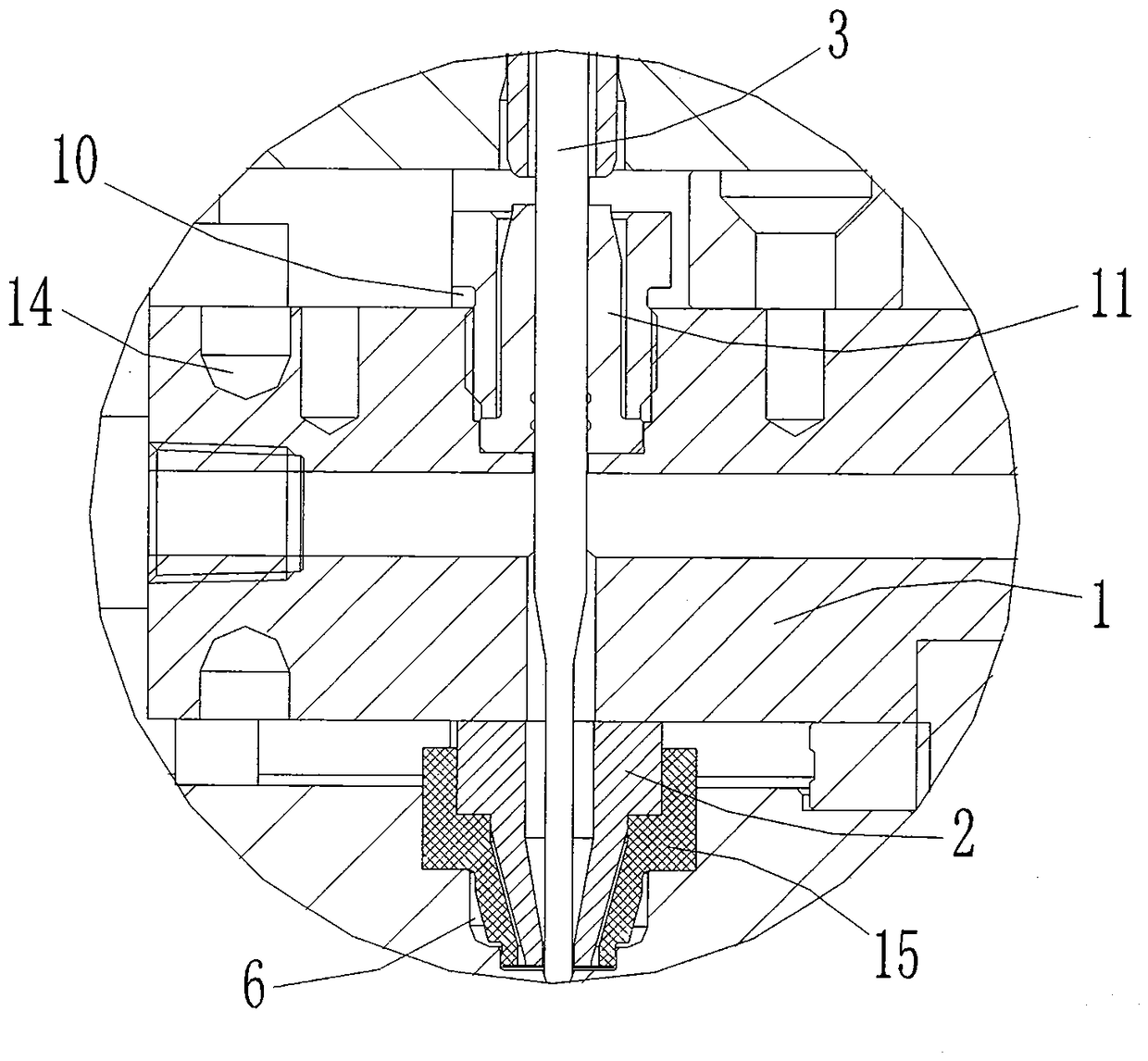

[0020] as attached figure 1 and attached figure 2 As shown, a low-pressure non-runner glue injection device includes a glue injection part and a mold part, and the glue injection part includes a glue gun body 1 with a cavity inside, and a cavity corresponding to the glue gun body 1 The penetrating gun nozzle 2, the valve needle 3 used to control the glue discharge from the gun nozzle 2, and the driving part used to drive the valve needle 3 to move, the glue gun body 1 has an internal cavity The connected glue outlet channel, part of the valve needle 3 is located in the gun nozzle 2 and the glue outlet channel, and the outside of the glue gun body 1 is provided with heating components; the mold part includes The upper template 4 and the lower template 5 for clamping and positioning the packaged product 9, the upper template 4 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com