Continuous sand-blast equipment for hubs

A technology of sandblasting equipment and wheel hubs, which is applied in metal processing equipment, used abrasive processing devices, abrasive jet machine tools, etc., can solve the problems of low sandblasting efficiency, achieve continuous sandblasting, facilitate recycling, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

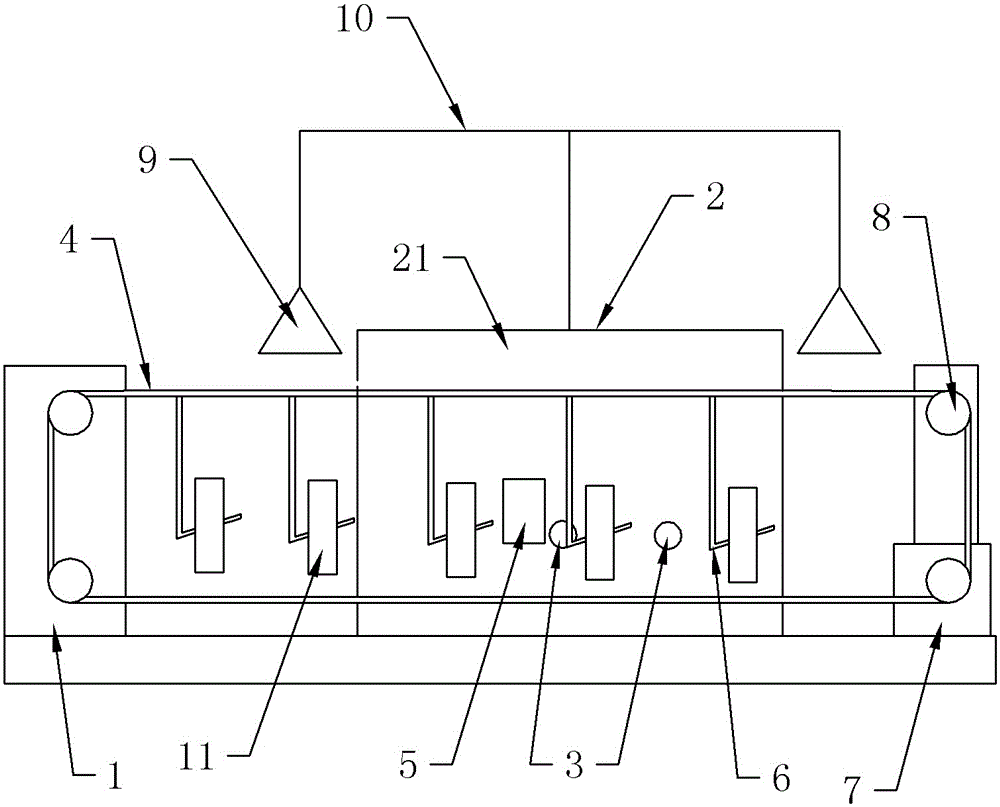

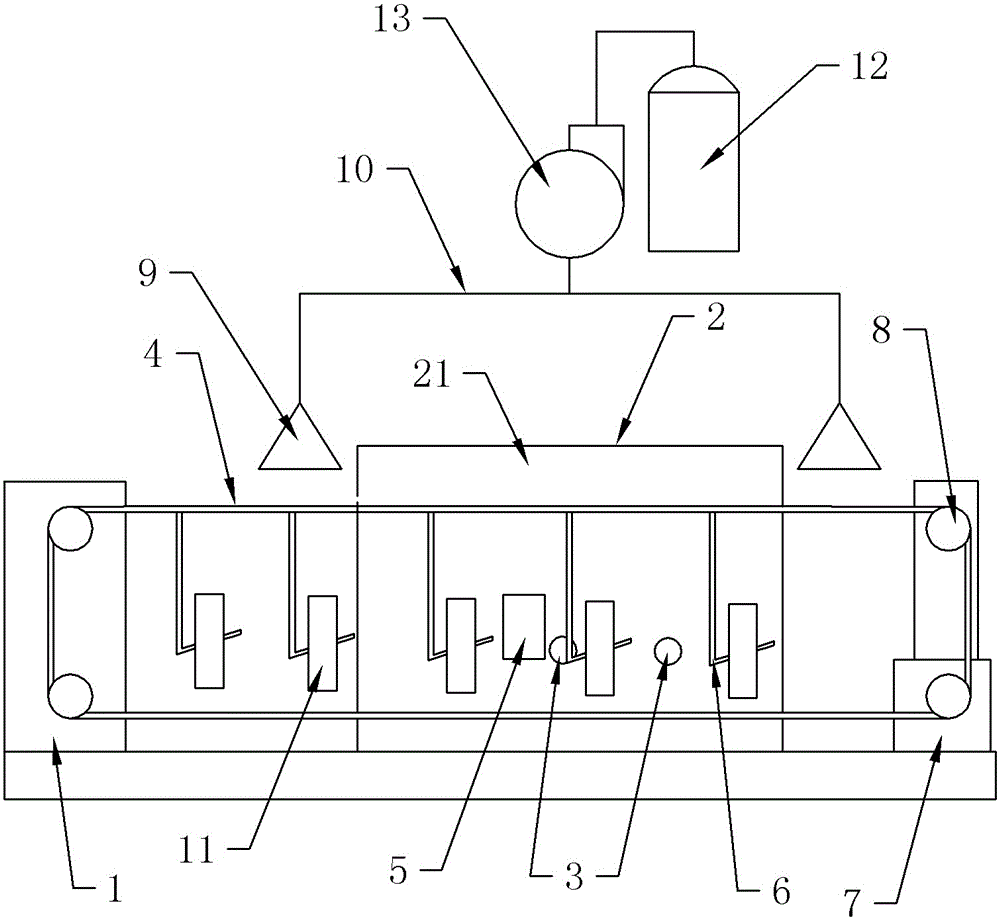

[0018] Such as figure 2 As shown, the difference from Embodiment 1 is that this embodiment also includes a gas-liquid separator 12 , and the end of the dust collecting pipe 10 away from the dust collecting hood 9 is connected to the gas-liquid separator 12 .

[0019] Specific workflow:

[0020] Take embodiment 1 as an example below to illustrate: figure 1 As shown, during use, hang the wheel hub 11 to be sandblasted on the hook 6, start the motor 7, and open the sandblasting nozzle 3, the motor 7 drives a sprocket 8 to rotate, and under the drive of the sprocket 8, the chain 4 follows The hour hand moves, and the wheel hub 11 hung on the hook 6 enters the sandblasting chamber 21 together with the chain 4, so that the sandblasting nozzle 3 sprays the abrasive on the wheel hub 11 surface. In this solution, since the chain 4 runs through the sandblasting chamber 21 through the feed port and the discharge port, and both ends extend out of the sandblasting chamber 21, it is only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com