Thermal shaping method and device of high-strength sharp-corner square rectangular tube

A square and rectangular tube, hot-shaping technology, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of inability to complete high-strength sharp-angled square and rectangular tubes, uneven inner and outer corners, and reduced elongation, etc. Achieve the effect of improving work hardening, fast heating and increasing elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

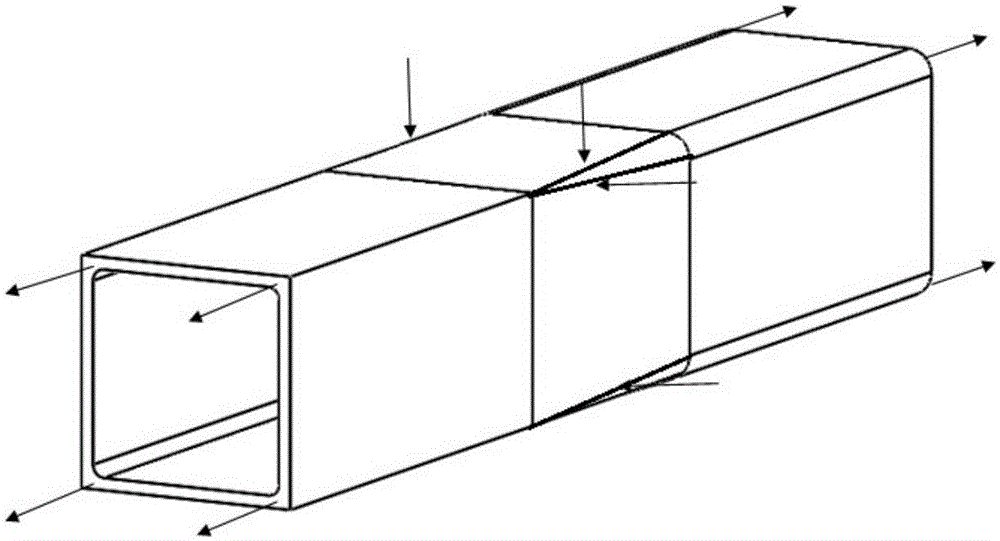

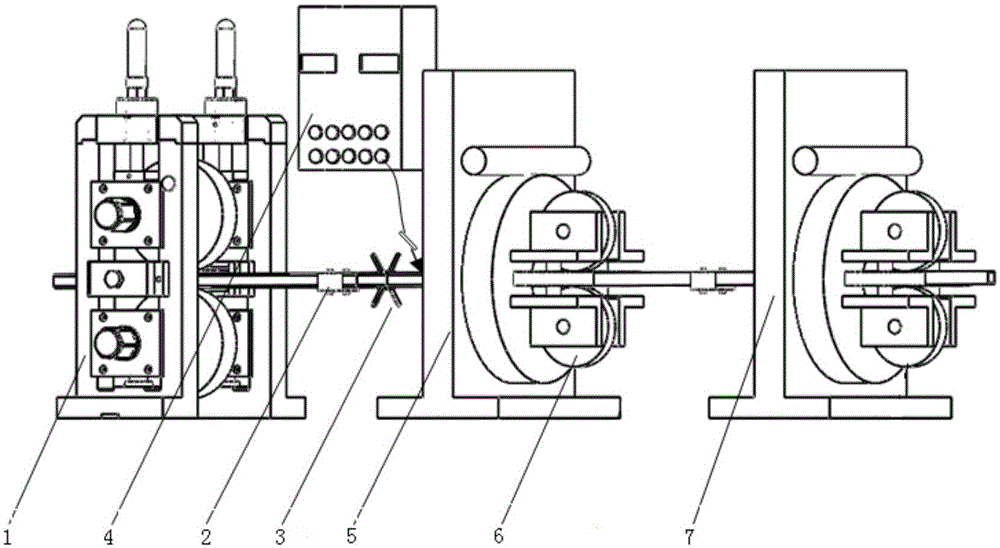

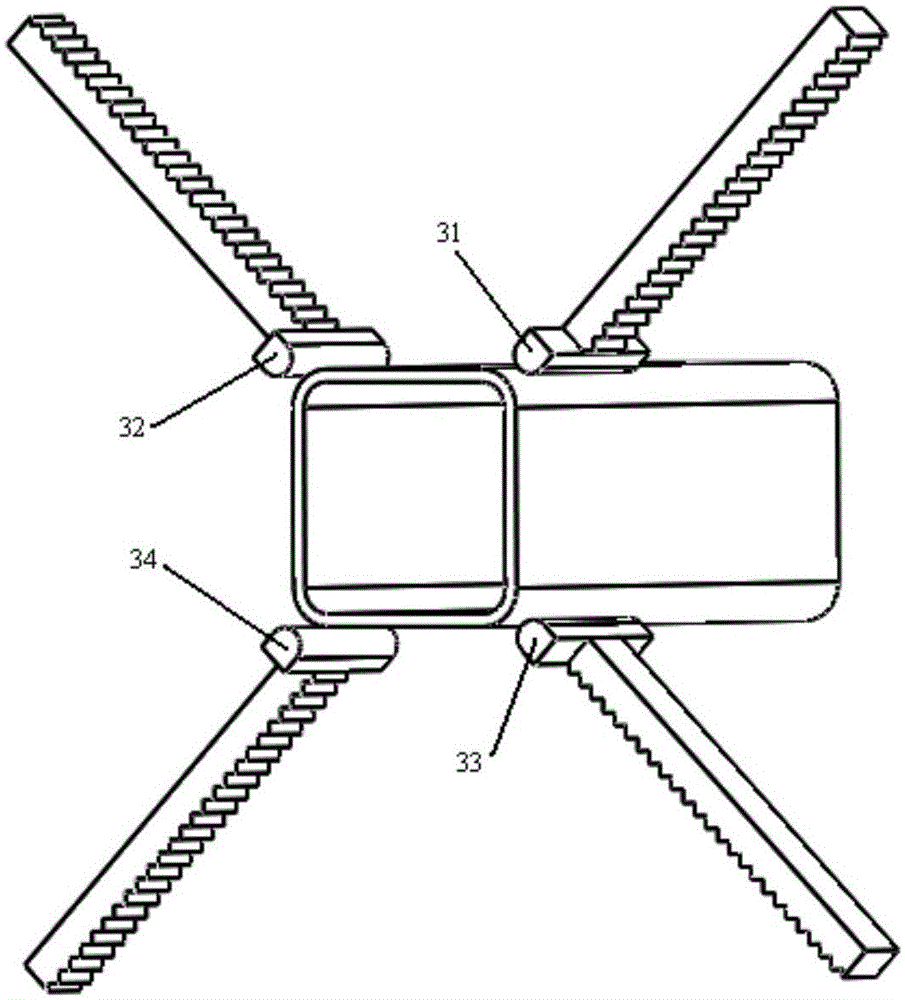

[0051] Pre-bend the high-strength steel plate (the material is QSTE700) into a preformed square rectangular tube with a fillet radius R=6mm (such as Figure 5 As shown), its size is 40.0×40.0×2.0mm; 2) At a feed rate of 10m / min, the fillet part of the preformed square and rectangular tube is rapidly heated to 600°C; 3) After hot extrusion and shaping, the obtained The size is 38.0×38.0×2.0mm, and the inner sharp angle square rectangular tube, its structure is as follows Image 6 shown.

[0052] After testing, for the QSTE700 material, the elongation rate is only 9% when cold-formed; however, the elongation rate at the bend angle returns to the raw material performance after thermal shaping in this embodiment, and the elongation rate reaches 20%.

Embodiment 2

[0054] Pre-bend the high-strength steel plate (QSTE700 material) into a pre-formed square rectangular tube with a fillet radius R=6mm (such as Figure 5 As shown), its size is 40.0×40.0×2.0mm; 2) At a feed rate of 10m / min, the fillet part of the preformed square and rectangular tube is rapidly heated to 800°C; 3) After hot extrusion and shaping, the obtained The size is 37.5×37.5×2.0mm, and the outer sharp corner square rectangular tube, its structure is as follows Figure 7 shown.

[0055] After testing, the elongation is only 5% when cold-bending; however, the elongation of the corner returns to the raw material properties after heat shaping in this embodiment, and the elongation reaches 18%.

[0056] It can be seen from the above that, compared with the cold-bending process, the work-hardening phenomenon of the square and rectangular tube of the present invention is reduced, the residual stress is reduced, and the elongation is greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com