Led module three anti-paint spraying fixture and its use method

A technology of LED modules and spraying fixtures, applied in the direction of spraying devices, etc., can solve the problems of time-consuming adjustment, unusable fixtures, pollution of lamp surfaces, etc., and achieve the effect of reducing cleaning steps, reducing production costs, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

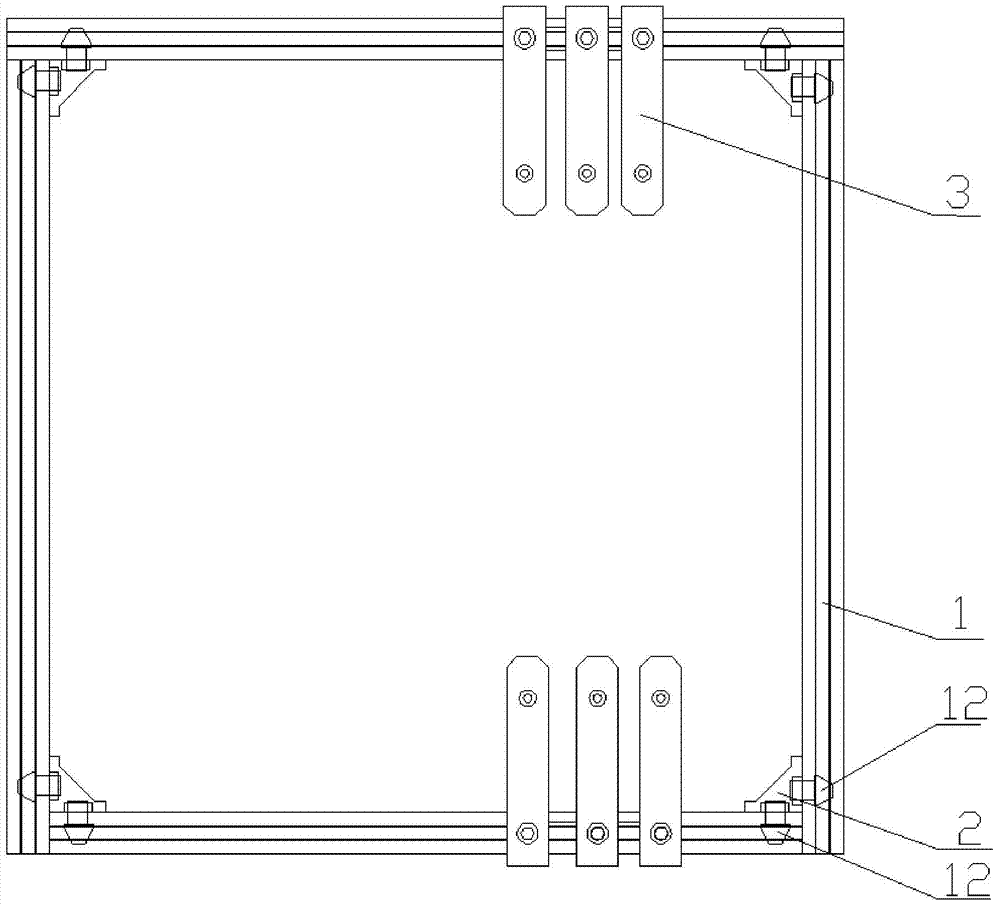

[0024] The LED module conformal paint spraying fixture proposed by the present invention includes:

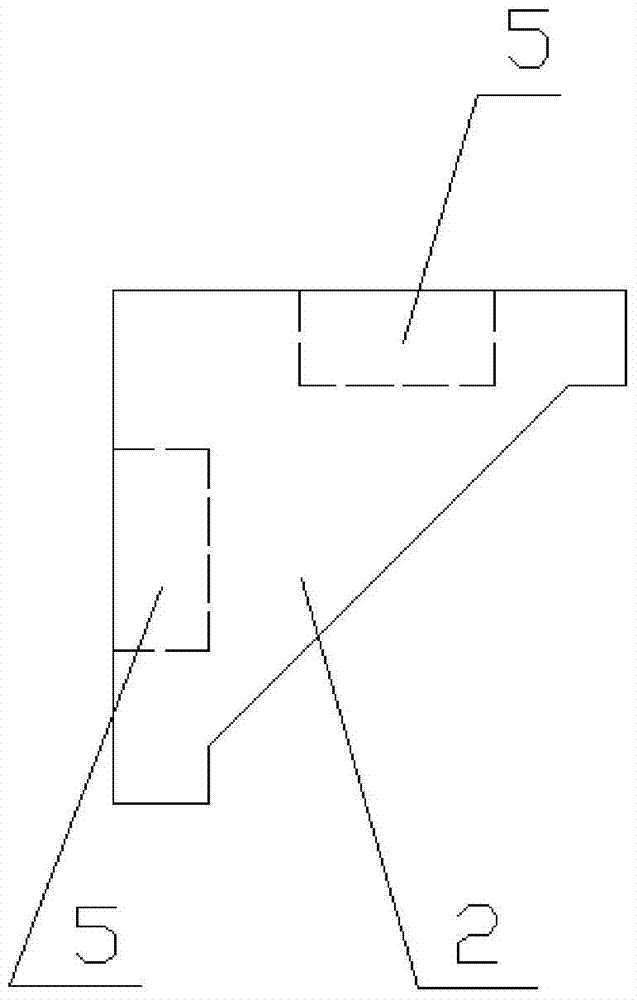

[0025] Four crossbeams 1, four crossbeams 1 are connected successively to form a closed rectangle, the four sides of the crossbeam 1 are respectively provided with grooves 4 adapted to the head of the bolt; the outside of the groove 4 is provided with a channel 6 adapted to the shaft of the bolt , the diameter of the channel 6 is smaller than the diameter of the groove 4;

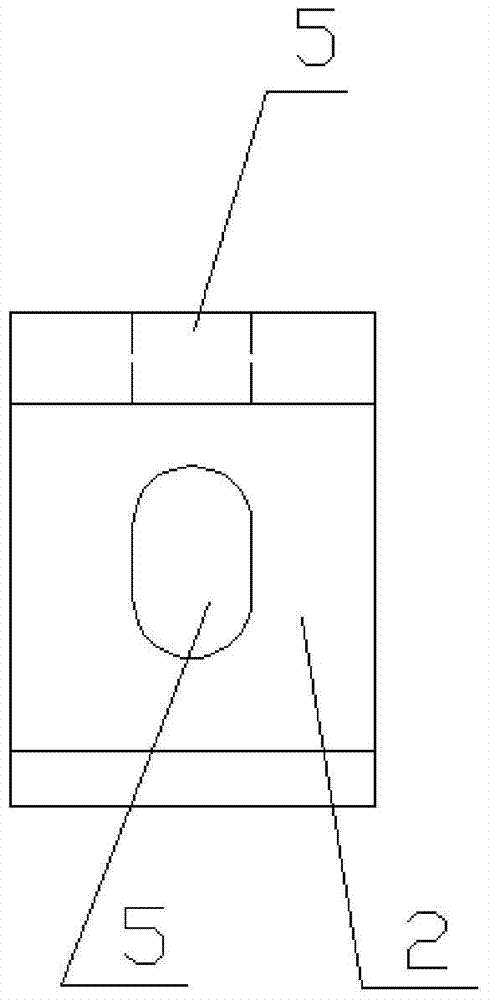

[0026] The four corner codes 2 are respectively provided with holes 5 for passing through bolt shafts on the vertically adjacent two sides of the corner codes 2;

[0027] Several sets of support frames 3, the support frames 3 are relatively arranged on two opposite beams 1, the support frames 3 include a frame body 7, and a handle 8 arranged on one side of the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com