A robot continuous automatic painting equipment for large workpieces

A technology for automatic painting and large workpieces, applied in the direction of painting booths, spraying devices, etc., can solve the problems of difficulty in replacing and cleaning nozzles, difficulty in continuous operation, low automation level, etc., to improve economy, reduce pollution, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

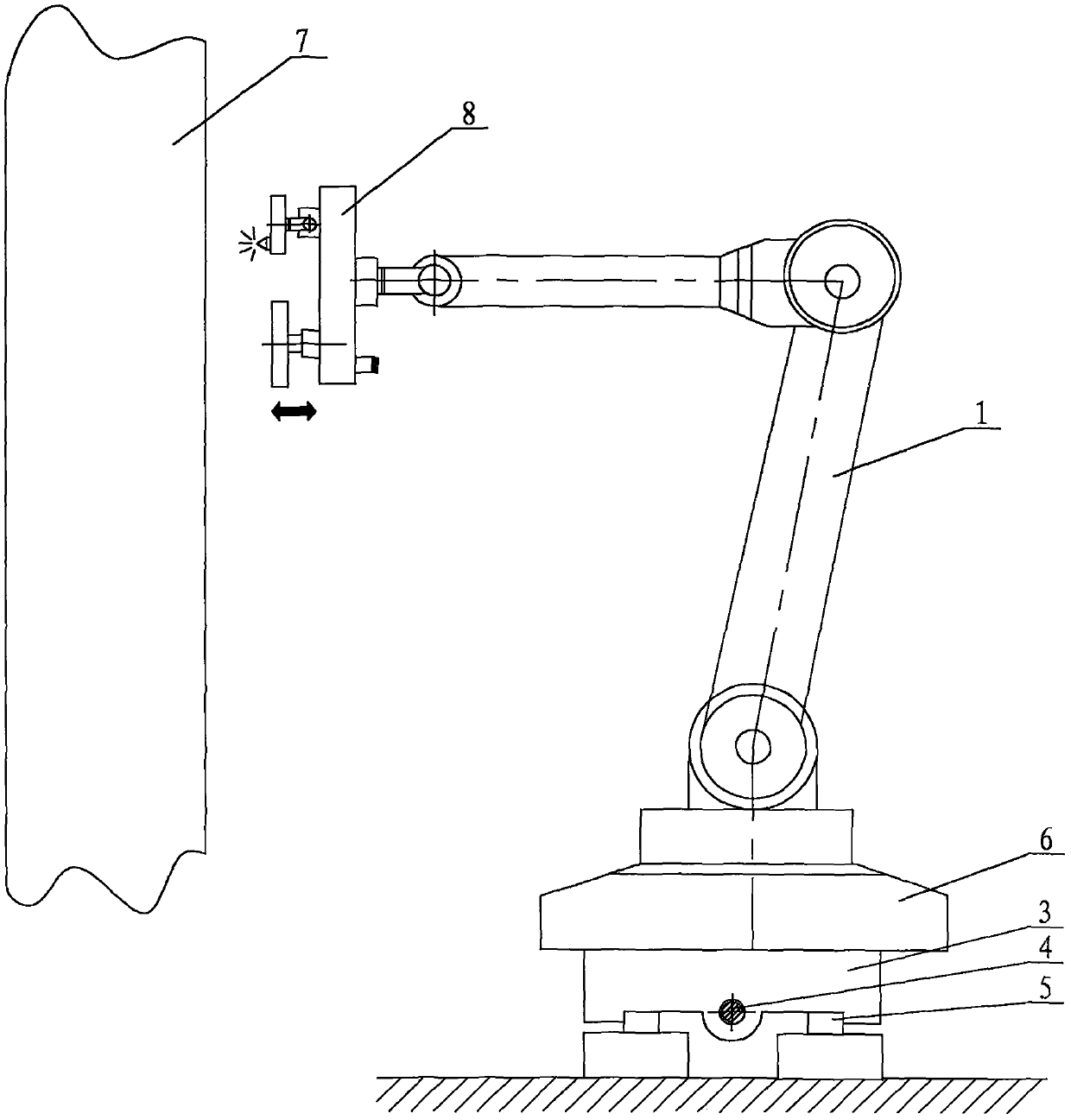

[0020] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment, this embodiment comprises industrial robot 1, mobile platform 3, lead screw 4, track 5, base 6 and spraying device 8, the afterbody of industrial robot 1 is fixed on mobile platform 3 by base 6, mobile platform 3 It is threadedly connected with the lead screw 4, the mobile platform 3 is slidably connected with the track 5, and the spraying device 8 is installed at the end of the industrial robot 1;

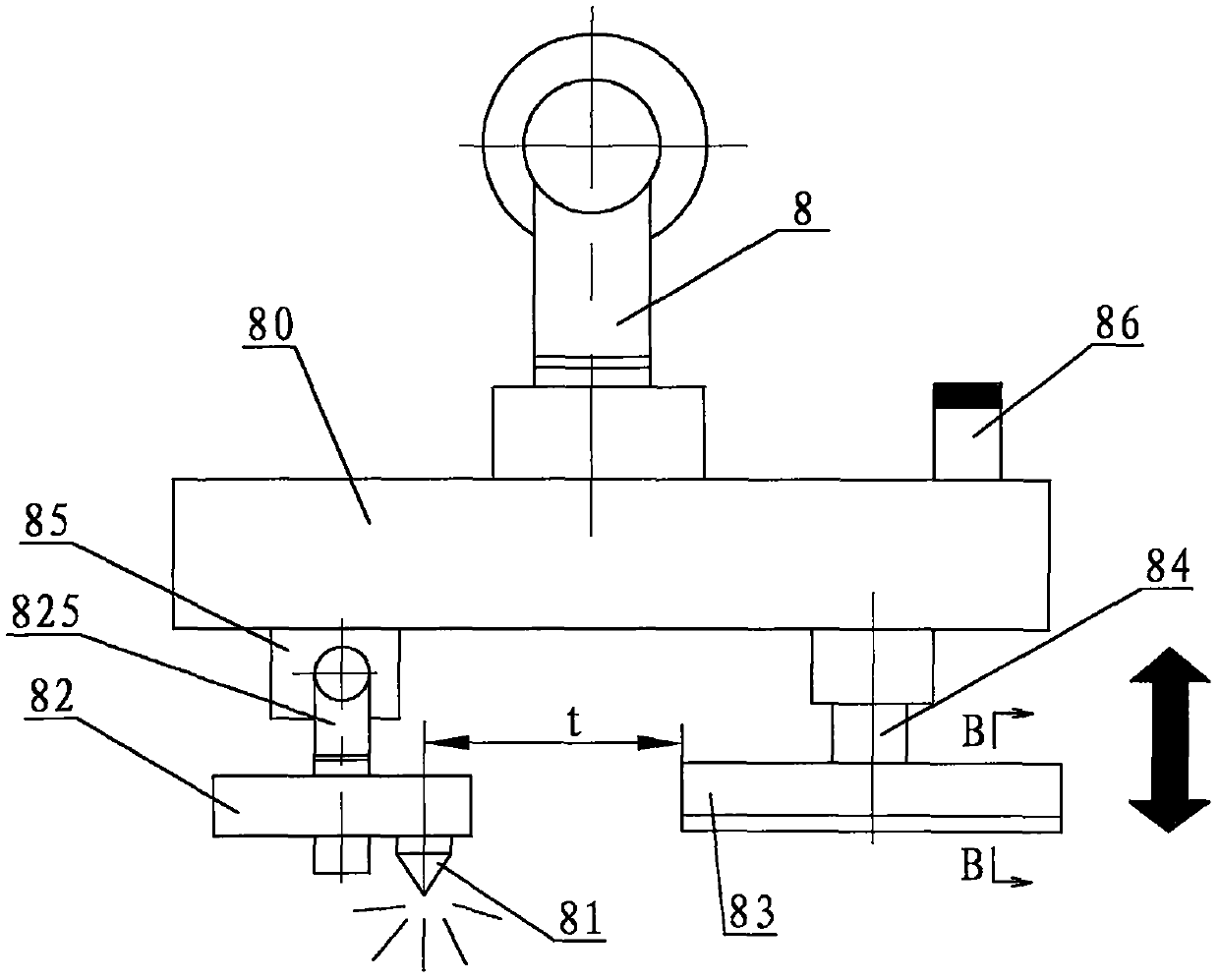

[0021] The spraying device 8 includes a mounting base 80, a main spray head 81, a cleaning device 82, a drying device 83, a cylinder 84, a driving part 85 and a distance sensor 86;

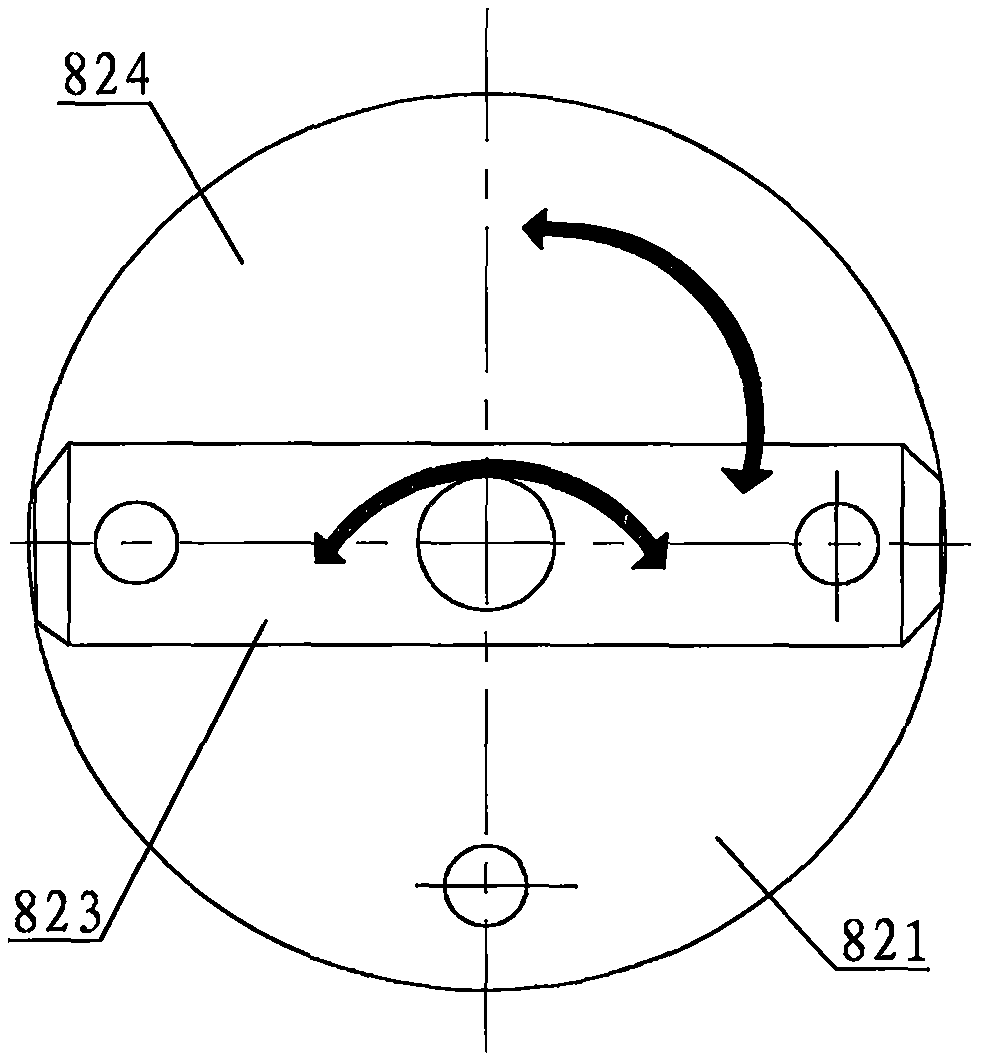

[0022] The cleaning device 82 includes a bottom plate 821, an automatic nozzle replacement device 823, a driving spindle 825, a nozzle library sealing upper cover 824, an ultrasonic transducer 826, an ultrasonic generator 827 and several nozzles to be replaced 822. The central position of the bottom plate ...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination Figure 5 The present embodiment will be described. The ultrasonic frequency of the ultrasonic generator 827 of the present embodiment is 50 KHZ to 100 KHZ. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 5 The present embodiment will be described. The ultrasonic frequency of the ultrasonic generator 827 of the present embodiment is 80KHZ. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com