Preparation method for CuO/ZnO catalyst

A catalyst and aqueous solution technology, which is applied in the field of preparation of catalysts and CuO/ZnO catalysts, can solve the problems of uncontrollable ZnO exposed crystal planes, etc., and achieve the effects of large-scale production, good catalytic performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing CuO / ZnO catalyst is to first prepare ZnO crystals with preferential crystal planes by hydrothermal method, and then use mechanical grinding method to load CuO. The preparation process specifically includes the following steps:

[0026] (1) Weigh 5.00 g of zinc acetate and add it to 20 mL of deionized water to obtain an aqueous solution of zinc acetate with a concentration of 0.57 mol / L;

[0027] Weigh 3.19g of hexamethylenetetramine and add it to 20mL of deionized water to obtain a 0.57mol / L hexamethylenetetramine aqueous solution;

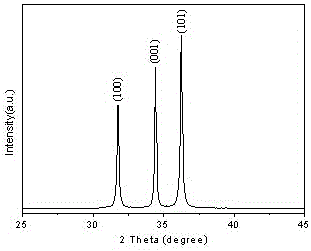

[0028] (2) Mix the hexamethylenetetramine aqueous solution and the zinc acetate aqueous solution in equal volumes and stir evenly to obtain a mixed solution. Transfer the mixed solution to a reaction kettle, keep it at 95°C for 12h, slowly cool to room temperature, and wash the white precipitate by centrifugation with distilled water and absolute ethanol for several times. The resulting white precipitate is dried at 60°C fo...

Embodiment 2

[0031] A method for preparing CuO / ZnO catalyst is to first prepare ZnO crystals with preferential crystal planes by hydrothermal method, and then use mechanical grinding method to load CuO. The preparation process specifically includes the following steps:

[0032] (1) Weigh 5.00 g of zinc acetate and add it to 20 mL of deionized water to obtain an aqueous solution of zinc acetate with a concentration of 0.57 mol / L;

[0033] Weigh 3.19g of hexamethylenetetramine and add it to 20mL of deionized water to obtain a 0.57mol / L hexamethylenetetramine aqueous solution;

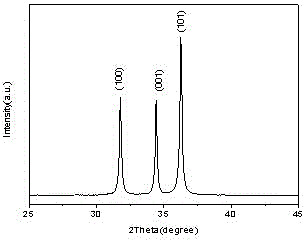

[0034] (2) Mix the hexamethylenetetramine aqueous solution and the zinc acetate aqueous solution in equal volumes and stir evenly to obtain a mixed solution. Transfer the mixed solution to the reaction kettle, keep it at 95°C for 16h, slowly cool to room temperature, and wash the white precipitate by centrifugation with distilled water and absolute ethanol for several times. The resulting white precipitate is dried at 60°C ...

Embodiment 3

[0037] A method for preparing CuO / ZnO catalyst is to first prepare ZnO crystals with preferential crystal faces by using a hydrothermal method, and then use a mechanical grinding method to load CuO. The preparation process specifically includes the following steps:

[0038] (1) Weigh 5.00g zinc acetate and add it to 20mL deionized water to obtain a zinc acetate aqueous solution with a concentration of 0.57mol / L;

[0039] Weigh 3.19g of hexamethylenetetramine and add it to 20mL of deionized water to obtain a 0.57mol / L hexamethylenetetramine aqueous solution;

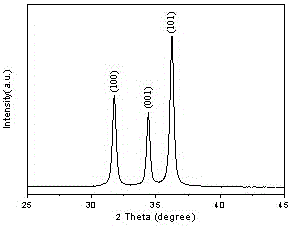

[0040] (2) Mix the hexamethylenetetramine aqueous solution and the zinc acetate aqueous solution in equal volumes and stir evenly to obtain a mixed solution. Transfer the mixed solution to the reaction kettle, keep it at 95°C for 24h, slowly cool to room temperature, and wash the white precipitate by centrifugation with distilled water and absolute ethanol for several times. The obtained white precipitate is dried at 60°C for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com