Rotary battery material heating kettle

A battery material and heating kettle technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, heat treatment, etc., can solve the problems of high fuel consumption and low temperature control accuracy of heating kettles, achieve wide application, shorten sintering time, and facilitate maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

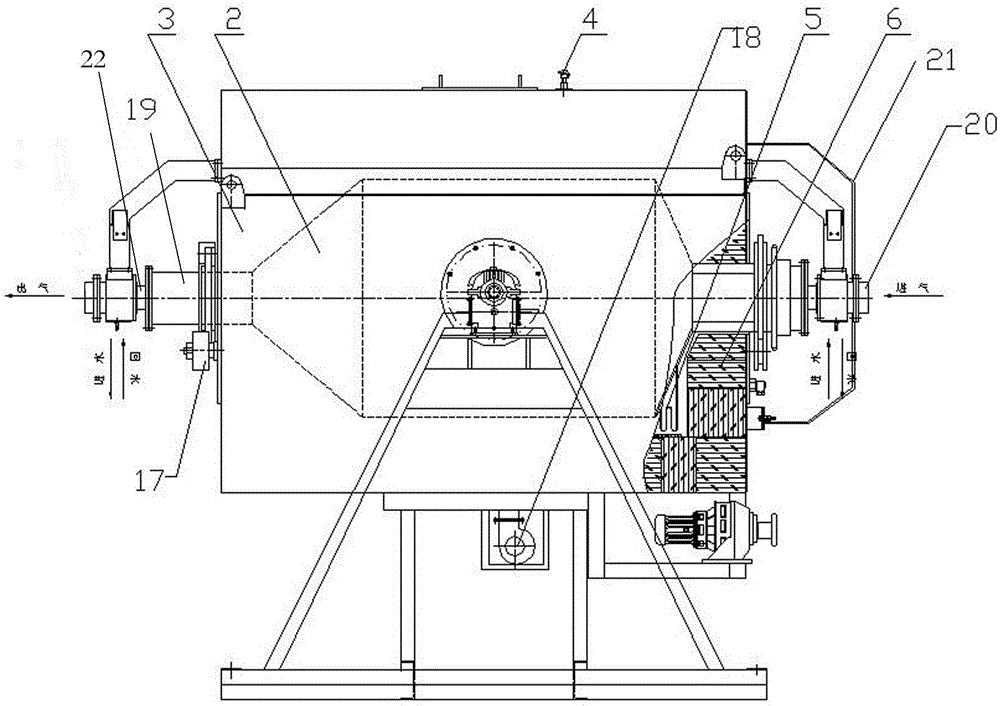

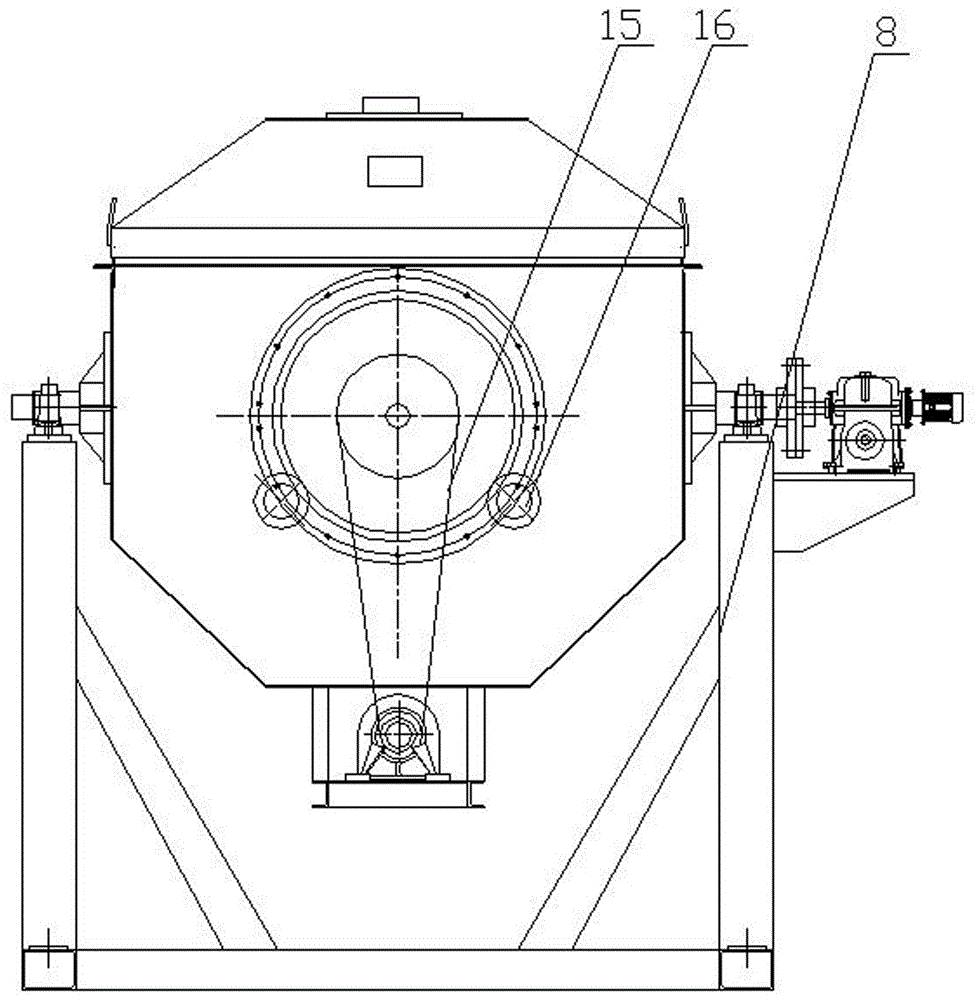

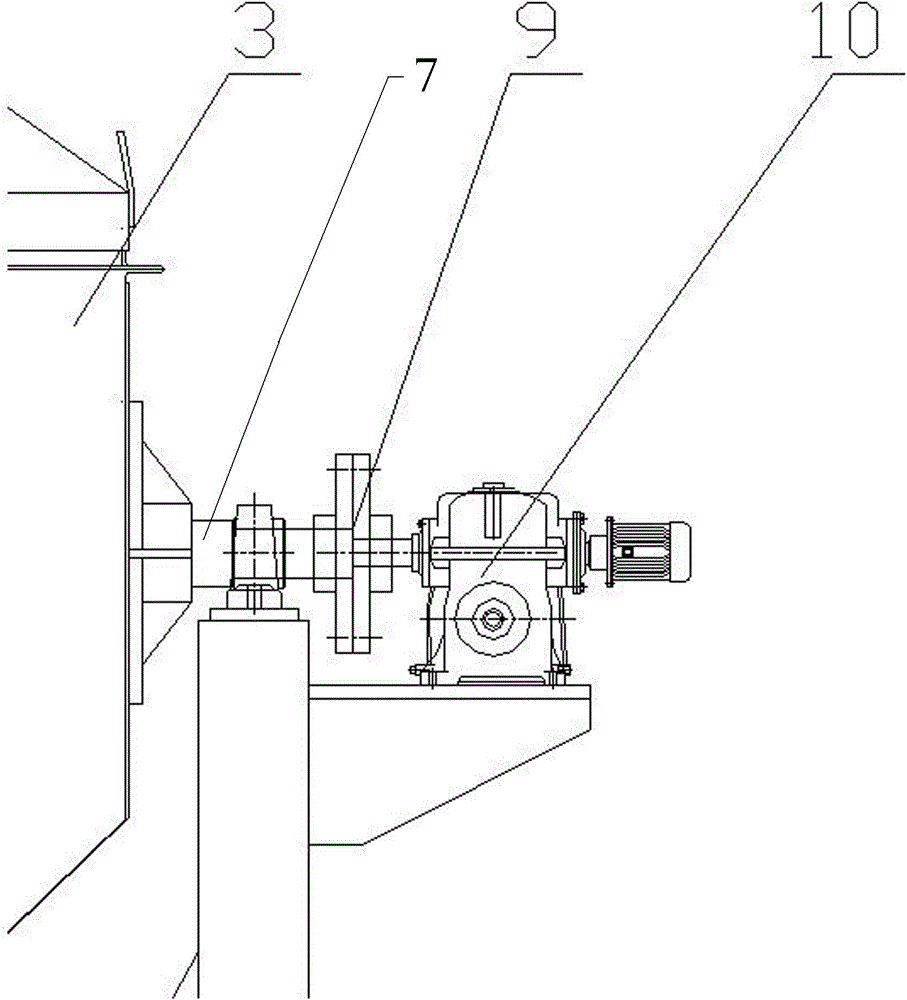

[0032] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

[0033] Such as Figure 1-9 As shown, the present invention is a rotary battery material heating kettle, which includes an outer casing 3 supported by an outer casing bracket 8. The outer casing 3 is welded by section steel and plate materials. This structure is convenient for maintenance, replacement and heating Components, the joints are fixed with high-strength bolts to form a whole, and asbestos boards are used as a heat insulation layer to prevent heat loss; a furnace lining 6 made of aluminum silicate fiber folded blocks is arranged inside the outer shell 3, and the furnace lining 6 Compressed with heat-resistant steel rivets and fixed on the outer casing 3, on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com