Degradable starch-based hemostatic material, preparation method therefor and applications

A hemostatic material and a technology for degrading starch, applied in the field of degradable starch-based hemostatic materials and their preparation, can solve the problems of limited activation of the coagulation system, unsatisfactory hemostatic effect, toxicity, etc., and achieve enrichment of the coagulation surface, promotion of platelet adhesion, and strong water absorption. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

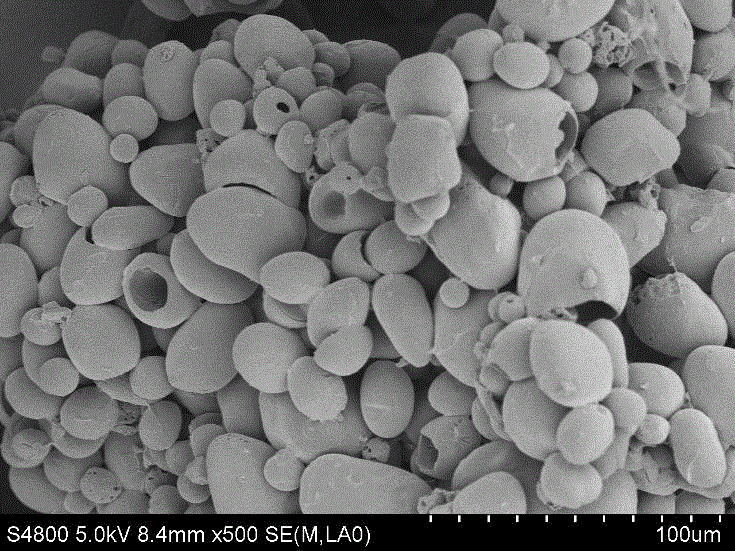

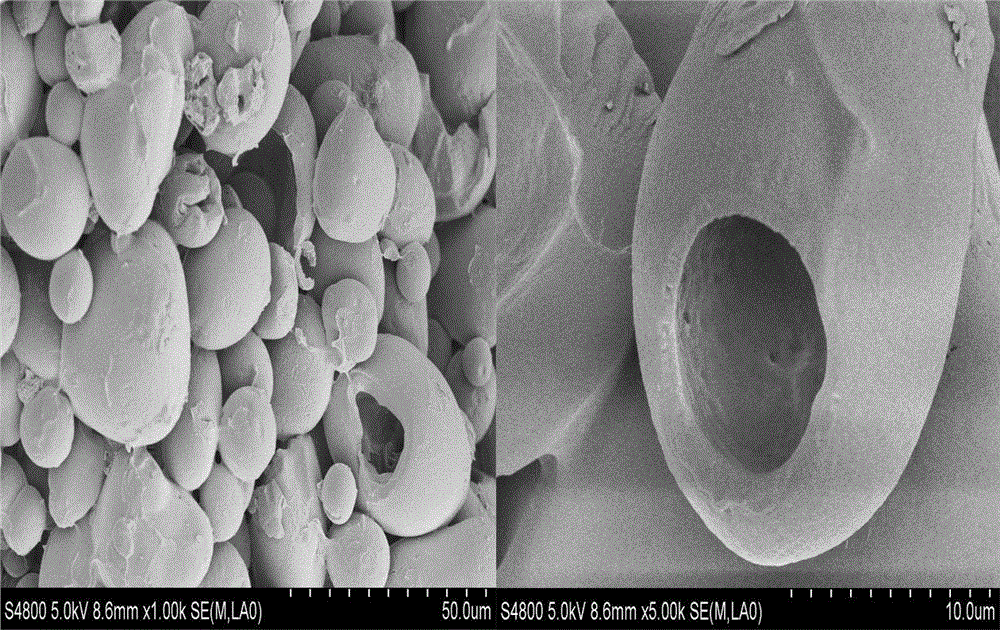

Image

Examples

Embodiment 1

[0044] Example 1: A kind of preparation method of degradable starch-based hemostatic material, it comprises the following steps:

[0045] S1. Raw material processing: washing mung bean starch with water;

[0046] S2. Ultrasonic treatment: Ultrasonic treatment is performed on the cleaned mung bean starch for 6 hours, the ultrasonic frequency is 15KHz, and the power is 1800W;

[0047] S3. Cross-linking: Add ultrapure water to mung bean starch, heat up to 30°C, add sodium chloride with a concentration of 1% (w / w) and sodium trimetaphosphate solution with a concentration of 2% (w / w), and keep warm for 10 minutes , adjust the pH value to 11 with 1.0 mol / L sodium hydroxide, stir and react for 2 hours, neutralize with 1.0 mol / L hydrochloric acid until the pH value of the solution is 6, obtain cross-linked starch and wash it;

[0048] S4. Enzyme pore making: mix cross-linked starch, calcium chloride, and ɑ-amylase for 2 hours, and the weight ratio of cross-linked starch, calcium ch...

Embodiment 2

[0049] Example 2: A kind of preparation method of degradable starch-based hemostatic material, it comprises the following steps:

[0050] S1. Raw material processing: washing the sweet potato starch with water;

[0051] S2. Cross-linking: Add ultrapure water to sweet potato starch, heat up to 70°C, add sodium chloride with a concentration of 5% (w / w) and sodium trimetaphosphate solution with a concentration of 8% (w / w), and keep warm for 60 minutes , adjust the pH value to 11 with 1.0 mol / L sodium hydroxide, stir and react for 48 hours, neutralize with 1.0 mol / L hydrochloric acid until the pH value of the solution is 7, obtain cross-linked starch and wash it;

[0052] S3. Ultrasonic treatment: Ultrasonic treatment is performed on the cross-linked starch for 8 hours, the ultrasonic frequency is 25KHz, and the power is 2500W;

[0053] S4. Enzyme pore making: Mix and react ultrasonically treated cross-linked starch, calcium chloride, and ɑ-amylase for 24 hours, and the weight ...

Embodiment 3

[0054] Example 3: A kind of preparation method of degradable starch-based hemostatic material, it comprises the following steps:

[0055] S1. Raw material processing: washing the potato starch with water;

[0056] S2. Ultrasonic treatment: Ultrasonic treatment is carried out for 7 hours to the cleaned potato starch, the ultrasonic frequency is 18KHz, and the power is 2000W;

[0057] S3. Cross-linking: add ultrapure water to potato starch, add sodium chloride with a concentration of 2% (w / w) and sodium trimetaphosphate solution with a concentration of 4% (w / w) after heating up to 40°C, and keep warm for 25 minutes , adjust the pH value to 11 with 1.0 mol / L sodium hydroxide, stir and react for 20 hours, neutralize with 1.0 mol / L hydrochloric acid until the pH value of the solution is 6.5, obtain cross-linked starch and wash it;

[0058] S4. Enzyme pore making: mix cross-linked starch, calcium chloride, and ɑ-amylase for 10 hours, and the weight ratio of cross-linked starch, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com