CUP structure preventing high-pressure water mist splashing

A water mist and high-pressure technology, applied in the field of CUP structure, can solve the problems of high equipment cost, large process chamber volume, unfavorable machine miniaturization and cost control, and achieve low processing and installation costs, transparent appearance, and easy equipment maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

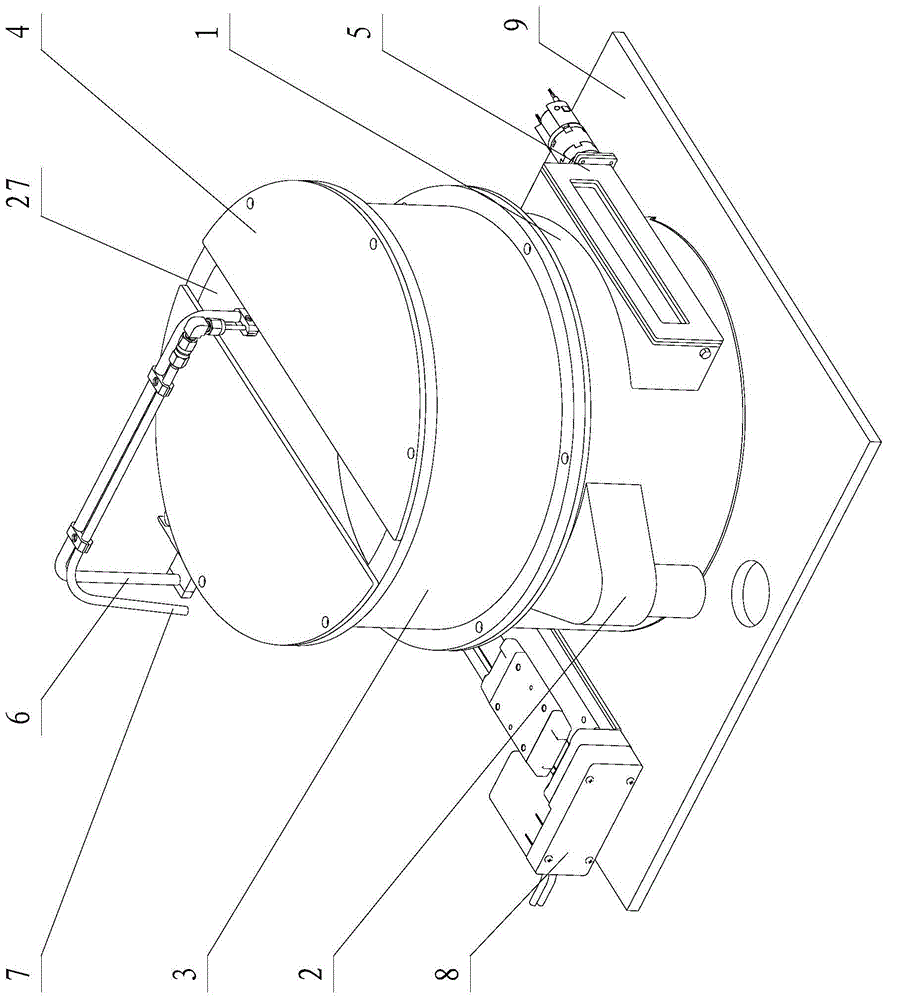

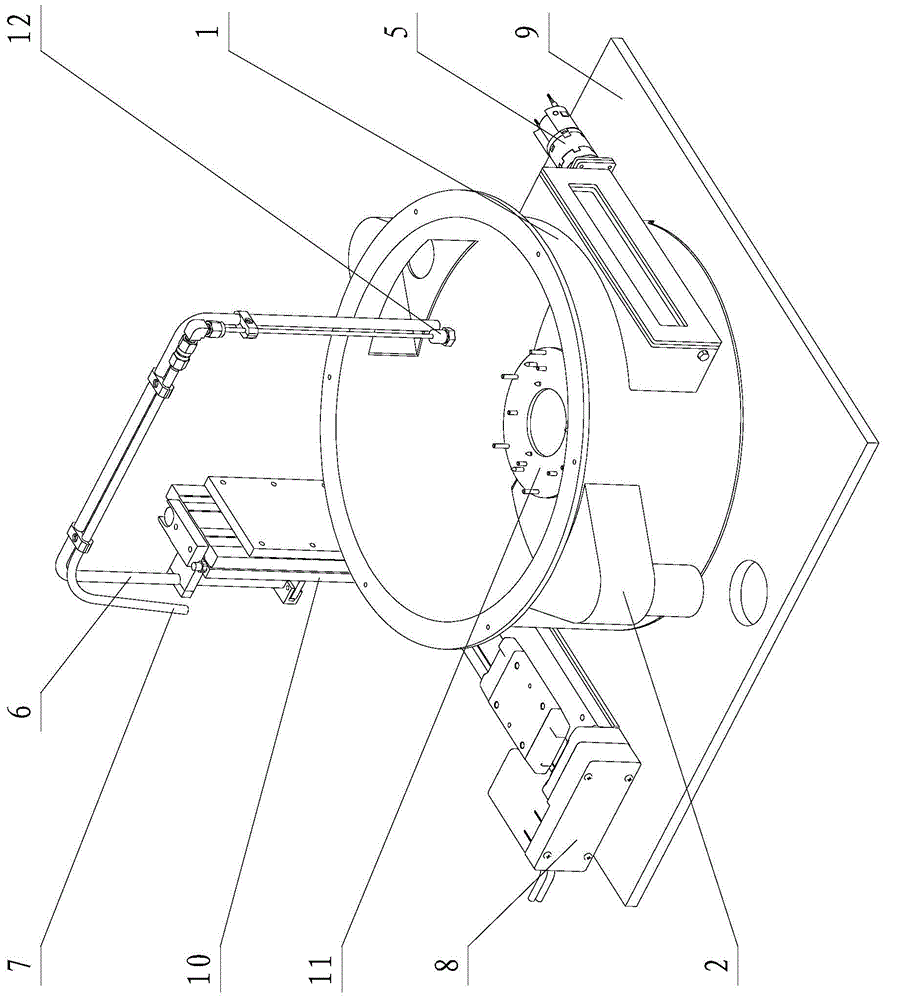

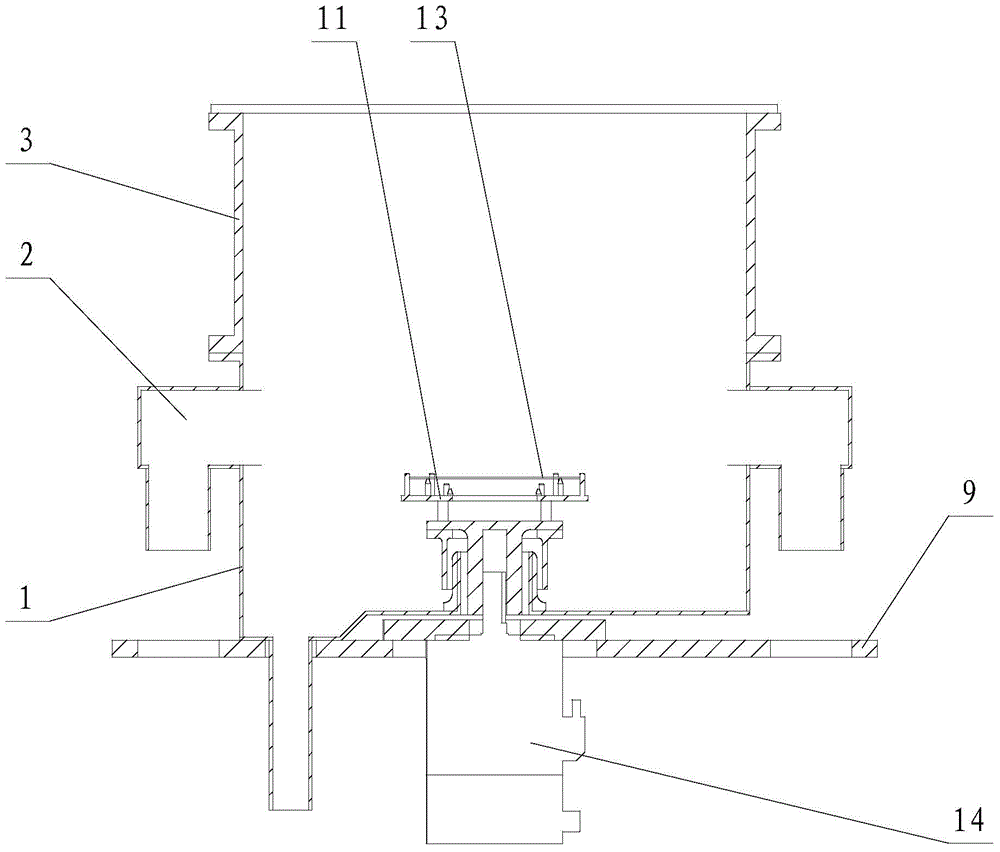

[0024] CUP (photoresist collection cup) structure of the present invention is as Figure 1~3 As shown, it includes CUP body, exhaust port 2, upper end cover 4, door opening mechanism 5, fixed support arm 6, liquid pipe 7, bottom plate 9, arm lifting mechanism 10, wafer chuck 11, nozzle 12, motor 14 and drive mechanism, wherein the CUP body is divided into detachable CUP base 1 and upper CUP3, the CUP base 1 is fixed on the bottom plate 9, the lower end of the upper CUP3 is connected with the CUP base 1 through screws, and the upper end cover 4 is installed on the upper end of the upper CUP3, The function of the upper end cover 4 is to reduce the opening size of the CUP structure, so that the exhaust air speed is higher and the wind direction is more concentrated. Both the upper CUP3 and the upper end cover 4 are made of transparent ECTFE (ethylene chlorotrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com