Electromagnetic circuit system and electromagnetic relay

A magnetic circuit system and electromagnetic technology, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of ineffective use of magnetic flux, low magnetic conduction efficiency of magnetic circuits, and easy magnetic saturation, etc., to achieve assembly process Good performance, good mold punching process, and the effect of reducing the probability of magnetic saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

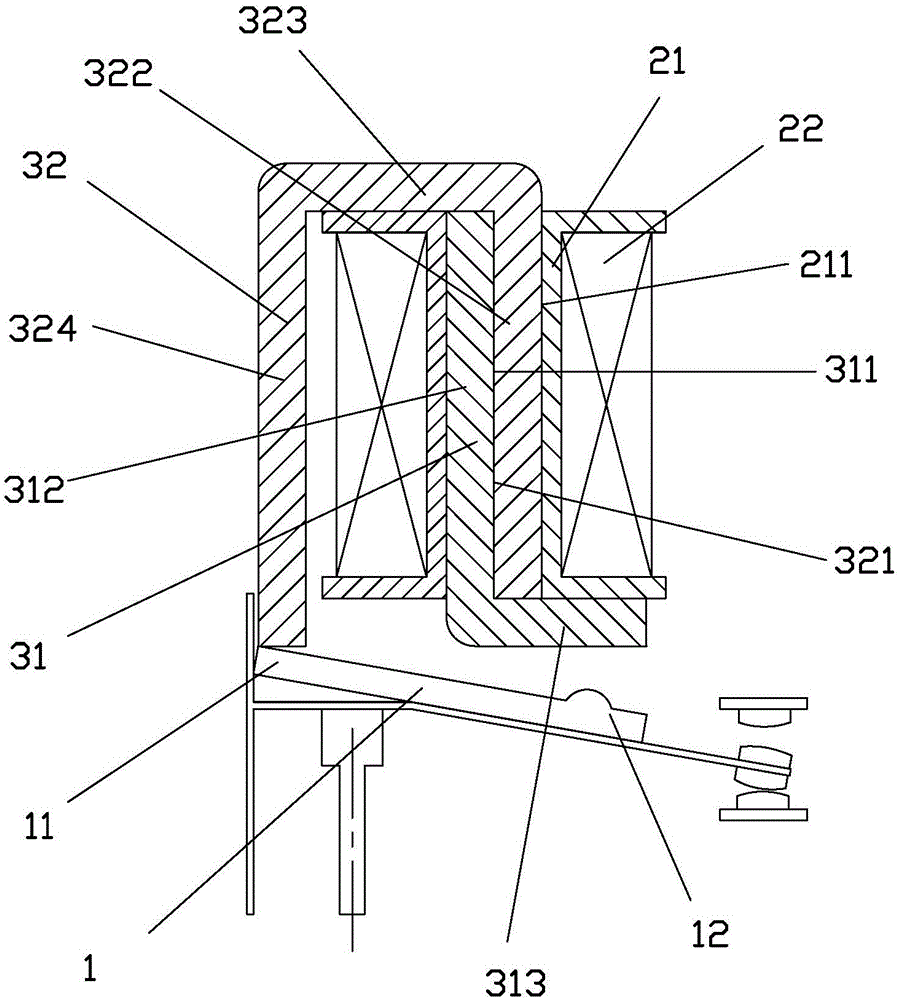

[0024] see figure 1 As shown, an electromagnetic magnetic circuit system of the present invention includes a yoke, an armature 1 and a coil; the coil is composed of a coil frame 21 and an enameled wire 22, and the coil frame 21 is provided with a through hole 211 for loading the iron core; The yoke is composed of a flat L-shaped yoke 31 and a flat U-shaped yoke 32, and one side 312 of the L-shaped yoke 31 and one side 322 of the U-shaped yoke 32 are formed by the coil frame respectively. The two ends of the through hole 211 are inserted into the through hole of the bobbin to abut against each other and constitute the iron core loaded into the through hole of the bobbin. The end edge of the other side 323 of the U-shaped yoke is used as a knife edge to support the One end 11 of the armature 1, and the other side 313 of the L-shaped yoke 31 is used as a pole surface to attract the other end 12 of the armature 1 when the coil is working.

[0025] One side 312 of the L-shaped yok...

Embodiment 2

[0035] see figure 2 As shown, an electromagnetic magnetic circuit system of the present invention is different from Embodiment 1 in that the electromagnetic magnetic circuit system is placed horizontally and is used for horizontal electromagnetic relays.

[0036] An electromagnetic relay of the present invention includes a horizontally placed electromagnetic magnetic circuit system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com