Work correcting method for automatic industrial device

A technology for industrial equipment and operations, applied in the field of operation correction of automated industrial equipment, can solve problems such as the failure of equipment workload to be transferred to other normal equipment in time, the need to redistribute operations, and the failure to detect failures of automated industrial equipment in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

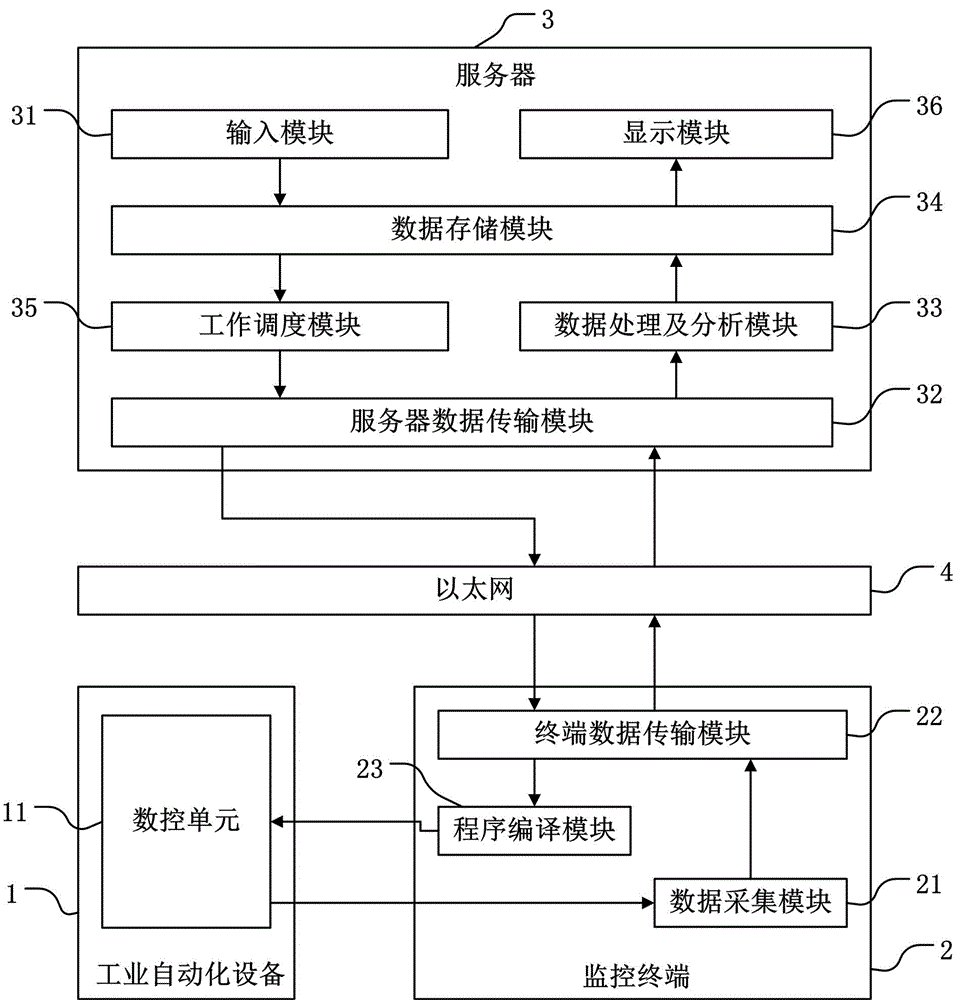

[0040] The present invention provides a job scheduling system for automated industrial equipment, which can also be referred to as a job scheduling system for automated industrial equipment, which is used to implement the job correction method for automated industrial equipment described in the present invention, and can be used for multiple different automated industrial equipment redistribute the workload.

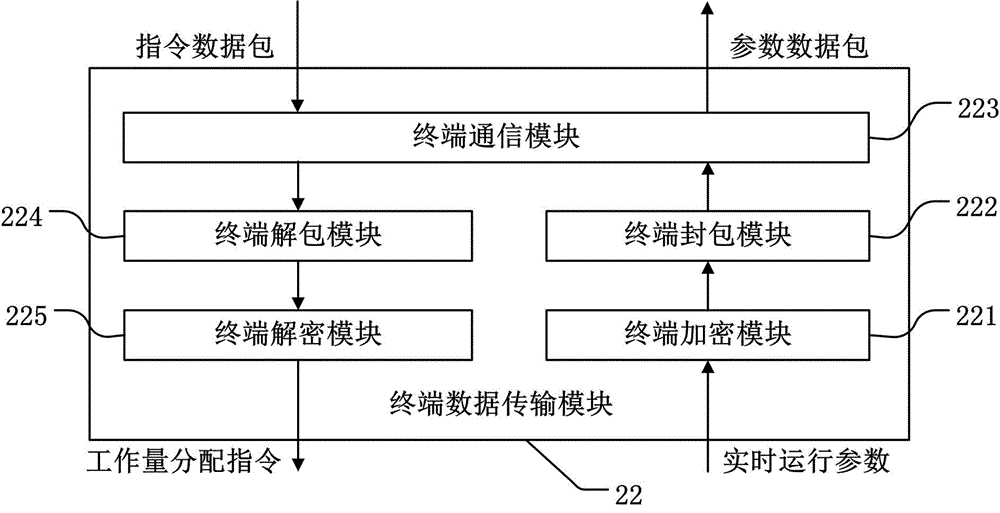

[0041] Such as figure 1 As shown, the job scheduling system of the automated industrial equipment includes: at least one automated industrial equipment 1, the automated industrial equipment 1 includes but not limited to industrial robots, CNC machine tools and machining centers; at least one monitoring terminal 2, each monitoring terminal 2 Corresponds to at least one automated industrial equipment 1 ; and at least one server 3 , ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com