A Method for Extracting Important Geometric Error Sources of Machine Tool Based on Extended Fourier Amplitude

A technology of geometric error and extraction method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as no solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

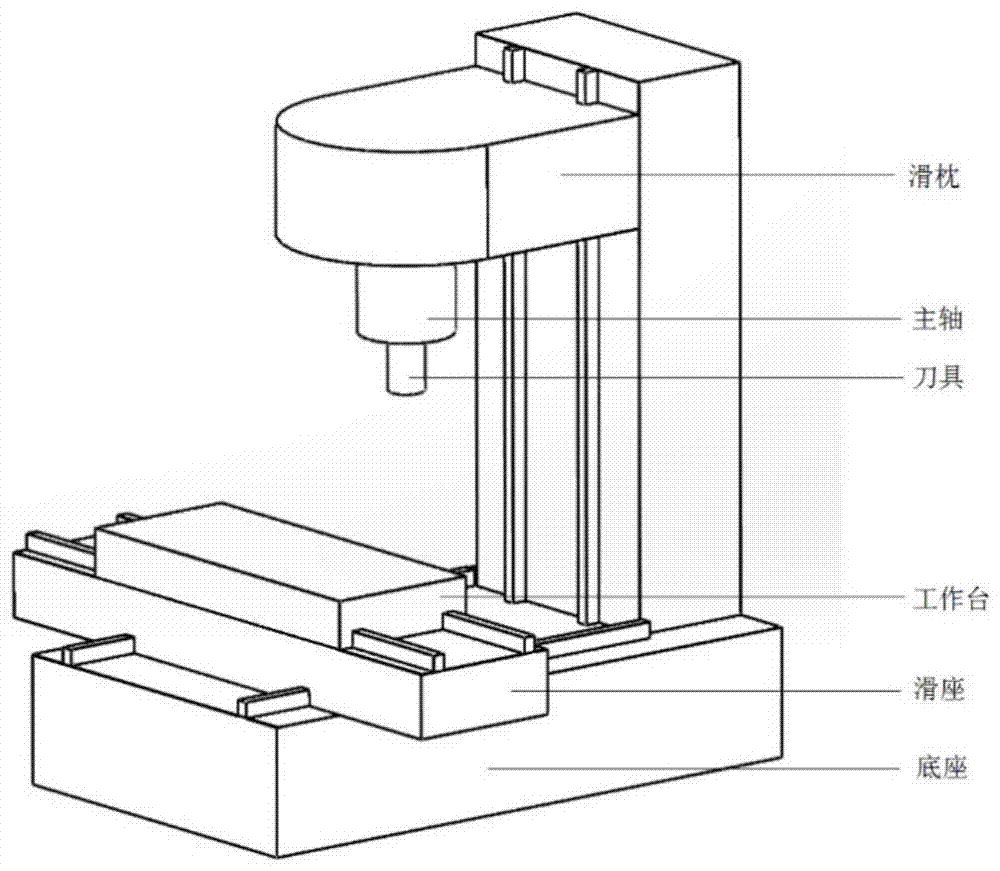

[0136] Calculation example: Take a three-axis linkage CNC machining machine tool as an example ( image 3 )

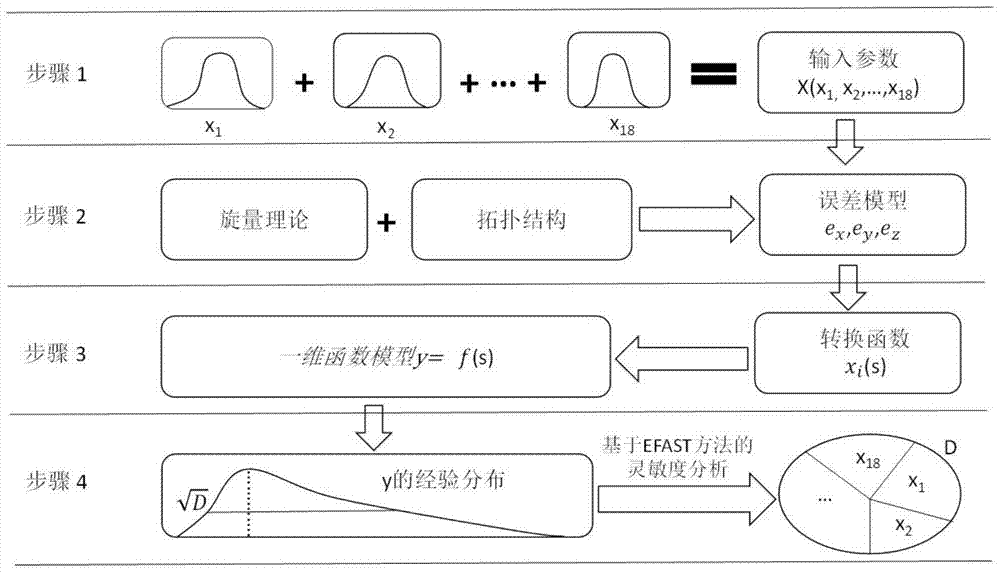

[0137] Step 1 Establish the spatial comprehensive error model of the machine tool according to the screw theory

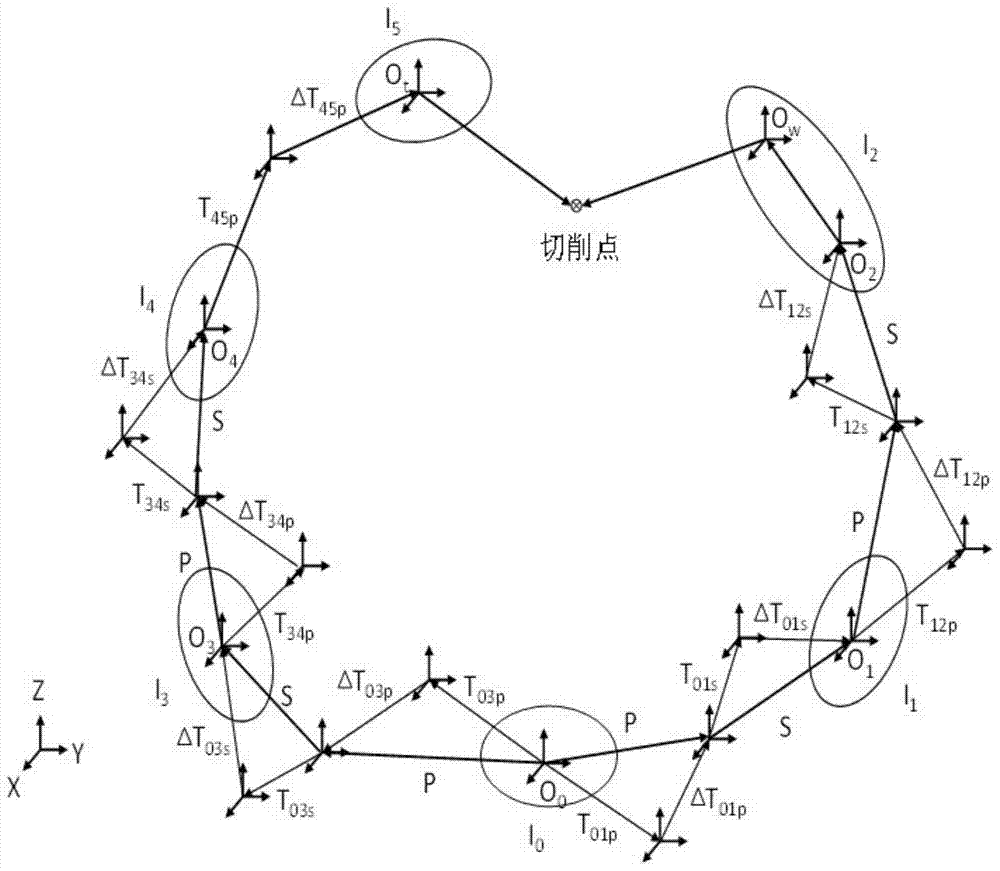

[0138] According to the exponential matrix form of the spinor theory, each movement part of the machine tool is abstracted into a 6×1 vector form. The motion form and error are modularized and expressed in the form of an exponential matrix. According to the topological structure of the machine tool ( figure 2 ) Establish the spatial error model of the machine tool.

[0139] Step 1.1 The exponential matrix form of spinor theory

[0140] The motion of any rigid body can be decomposed into two parts: translational motion along the axis and rotational motion around the axis. Each component can be regarded as a spin amount. The unit spin in Plücker coordinates is as follows:

[0141] Ψ=[k T u T ] T =[k 1 ,k 2 ,k 3 ,u 1 ,u 2 ,u 3 ] T (40)

[0142] To express the arbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com