Dynamic compensation method for ultrasonic flow meter

A dynamic compensation and ultrasonic technology, which is applied in the direction of volume measurement, flow/mass flow measurement, liquid/fluid solid measurement, etc., can solve the problem of increasing the amplitude of ultrasonic propagation signals, affecting the accuracy of flow measurement, and abnormal changes in ultrasonic propagation time measurement, etc. problem, to eliminate the deviation of flow calculation and improve the accuracy of flow calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

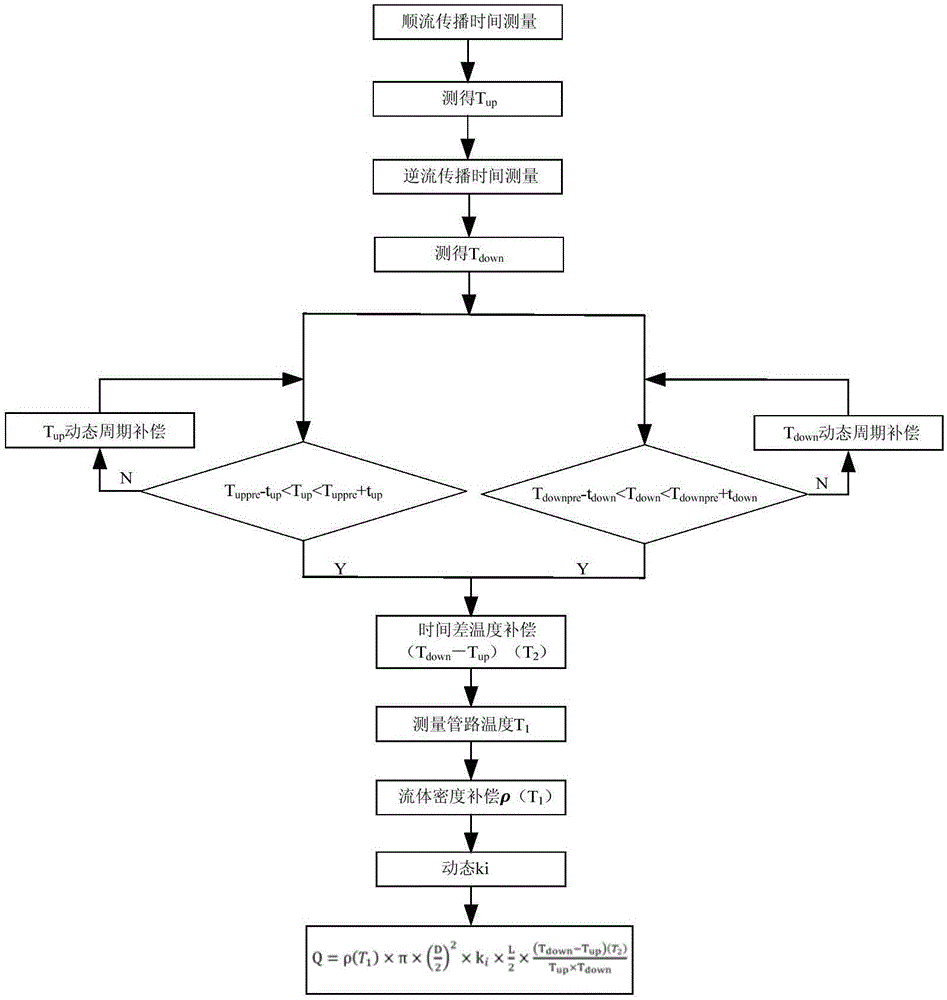

[0110] Utilize the ultrasonic flowmeter to measure the flow Q of the spacecraft propellant, and perform multi-stage dynamic compensation to the measured ultrasonic flowmeter, and the spacecraft propellant uses dinitrogen tetroxide fluid; see image 3 , first the upstream ultrasonic transducer transmits the signal, the downstream ultrasonic transducer receives the received signal, detects the rising edge of three consecutive zero-crossing pulses in the received signal exceeding a pre-triggering threshold as the stop timing enable signal, and the measured time is sequentially respectively recorded as and The measured ultrasonic wave traveling time along the current is denoted as T up ,T up The initial value of Then the downstream ultrasonic transducer transmits the signal, the upstream ultrasonic transducer receives the received signal, detects that the rising edge of three consecutive zero-crossing pulses in the received signal exceeds a pre-trigger threshold, and serves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com