A method for evaluating articular cartilage damage and wear

A technology of articular cartilage and evaluation method, which is applied in measurement devices, instruments, electric/magnetic profile/curvature measurement, etc., can solve the problems of misjudgment of surface damage, roughness, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

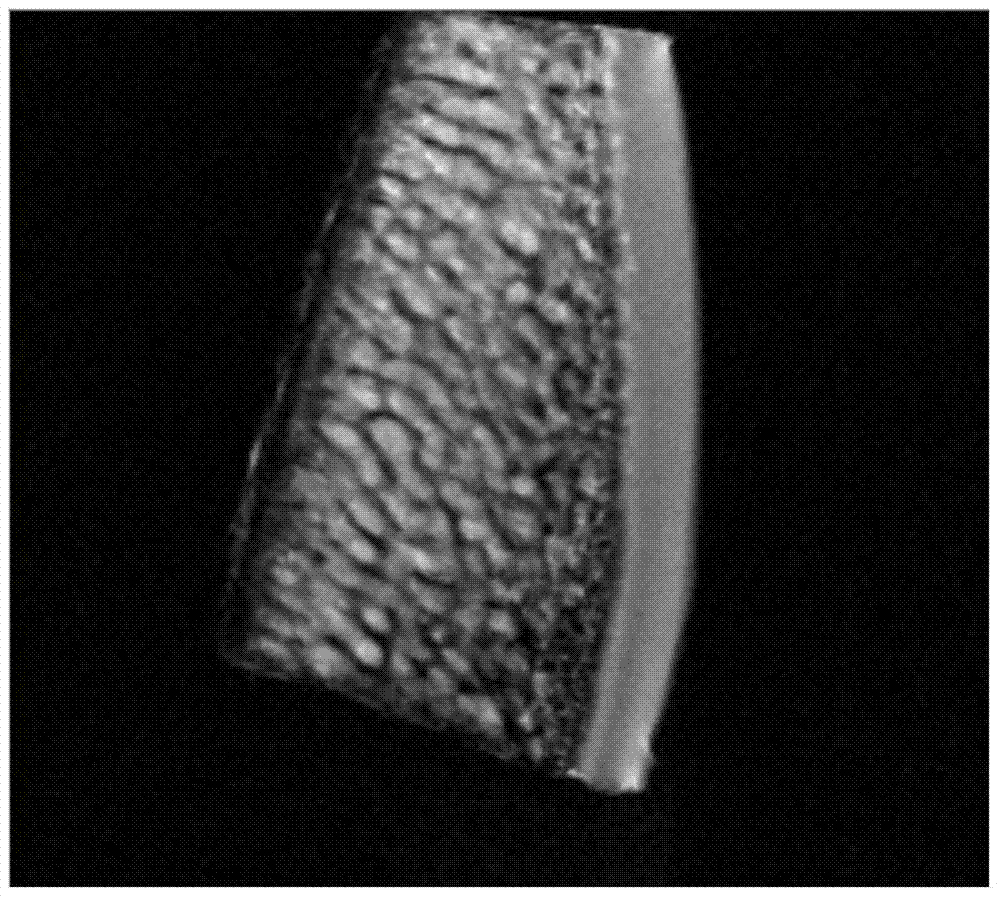

[0026] For bovine articular cartilage with low surface wear. The femoral condyle bone with bovine articular cartilage on the surface was cut into a fan shape with a thickness of 20 mm and a radian of 100°, and the fan-shaped bovine articular cartilage was fixed on the sample fixture with bone cement; the physiological movement of the femoral head was simulated on a swing test machine to gather The ethylene plate sample is used as the grinding pair, under the lubricating effect of 25% calf serum, the load is 150N, the swing frequency is 1Hz, and the swing cycle is 3600 revolutions, and the worn bovine articular cartilage is obtained as follows: figure 2 As shown; the segmented bovine articular cartilage wear area is divided into 13 slices and scanned in the MRI system. During the scanning process, the mode is 256×256 matrix, and the field of view is 20×20mm, so each pixel corresponds to The area is 6084μm 2 , while the slice thickness is 1 mm. Use Analyze 8.1 software to per...

Embodiment 2

[0028] For bovine articular cartilage with severe surface wear. The femoral condyle bone with bovine articular cartilage on the surface was cut into a fan shape with a thickness of 20 mm and a radian of 100°, and the fan-shaped bovine articular cartilage was fixed on the sample fixture with bone cement; the physiological movement of the femoral head was simulated on a swing test machine, and the The flat plate sample is used as the grinding pair, under the lubricating effect of 25% calf serum, the load is 350N, the swing frequency is 1Hz, and the swing cycle is 3600 revolutions, and the severely worn bovine articular cartilage is obtained as follows: Figure 5 As shown; the segmented bovine articular cartilage wear area is divided into 23 slices and scanned in the MRI system. During the scanning process, the mode is 256×256 matrix, and the field of view is 20×20mm, so each pixel corresponds to The area is 6084μm 2 , slice thickness is 1mm. Use Analyze 8.1 software to perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com