Pulley wearing amount measuring device of elevator

A technology for measuring device and wear amount, which is applied to measuring devices, optical devices, elevators in buildings, etc., can solve problems such as deviation error of stop position, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

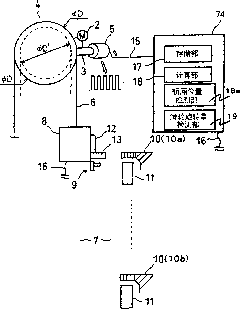

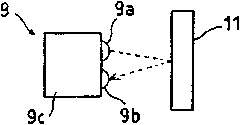

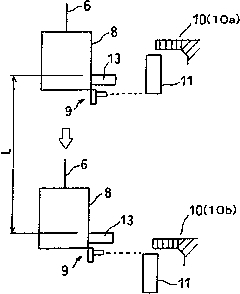

[0034] figure 1 It is an overall schematic view showing the sheave wear amount measuring device for an elevator according to the first embodiment. Fig. 2 is a schematic diagram illustrating a method of detecting a travel distance of a passenger car. image 3 It is a functional block diagram of the calculation unit of the wear amount of the pulley groove. In these drawings, the same symbols represent the same elements.

[0035] The pulley wear measurement device includes: a hoisting pulley 4 (pulley) directly connected to the engine shaft 3 of the engine 2, a pulse generator 5 that outputs a symbolic pulse signal according to the number of rotations of the engine shaft 3 and the rotation angle, and respectively winding Multiple (only one is shown in the figure) hoisting cables 6 on the hoisting pulley 4. The hoisting pulley 4 has a groove portion on which the hoisting cable 6 is wound. The hoisting pulley 4 and the engine 2 constitute a hoisting machine. The pulse generat...

no. 2 approach

[0077] The elevator sheave wear measuring device according to the second embodiment of the present invention similarly measures the effective diameter of the hoisting sheave 4 and measures the wear of the sheave groove surface in which the hoisting rope 6 is fitted.

[0078] The sheave wear amount measurement device of an elevator according to the present embodiment measures the wear amount by using a speed control device whose movement speed detection error is small by periodic calibration.

[0079] Figure 5 It is an overall schematic view of the elevator sheave wear measuring device according to the present embodiment. Figure 6 It is a functional block diagram of the calculation unit of the wear amount of the pulley groove. In these drawings, the same symbols as those appearing before represent the same constituent elements.

[0080] The pulley wear measurement device of the elevator comprises: a hoisting pulley 4 directly connected to the motor shaft 3 of the motor 2 of...

no. 3 approach

[0105] In the first embodiment, the modified example, and the second embodiment described above, any one of the pulley wear measuring devices may have the function of correcting the data of the effective diameter. The elevator sheave abrasion measuring device according to the third embodiment of the present invention measures the effective diameter of the hoisting sheave 4 and measures the abrasion of the sheave groove surface where the hoisting cable 6 is fitted.

[0106] Figure 7 It is a functional block diagram of the calculation part of the wear amount of a sheave groove in the elevator sheave wear amount measurement apparatus concerning this embodiment. In the pulley wear measuring device of the present embodiment, the function of the calculation unit 45 is provided in a calculation device in a control panel. The function of the calculation unit 45 is realized by CPU, ROM, RAM, and the like. The computing device has a function of storing the cable diameter of the hoist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com