Mine safety system and control method

A technology of safety system and control method, applied in the field of mine safety system and control, can solve the problems of low correlation, personal safety explosion, health hazards of staff, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

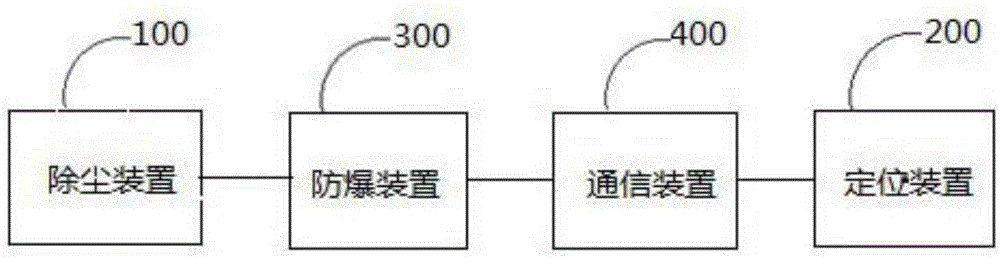

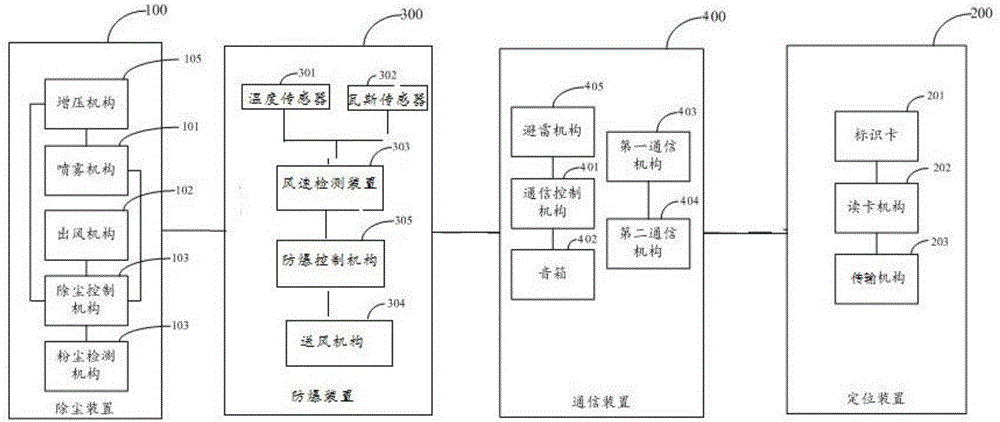

[0065] please if figure 1 As shown, this embodiment provides a mine safety system, including a dust removal device 100 for real-time monitoring of the dust concentration at a preset location under the mine, and dust removal when the dust concentration at the preset location is greater than the preset concentration; The positioning device 200 for real-time monitoring of the position of the staff in the mine; the pre-warning device 300 for detecting the temperature and gas concentration at the preset position in the mine in real time, and sending air when the temperature at the preset position or the gas concentration is greater than the preset value; Connected with the dust removal device 100, the positioning device 200 and the early warning device 300, when the dust concentration, temperature or gas concentration at the preset position under the mine is greater than the preset value, the communication device 400 is used to notify the staff .

[0066] Under the mine, especiall...

Embodiment 2

[0069] please if figure 2 As shown, the mine safety system provided by this embodiment is compared with Embodiment 1, and its difference lies in that

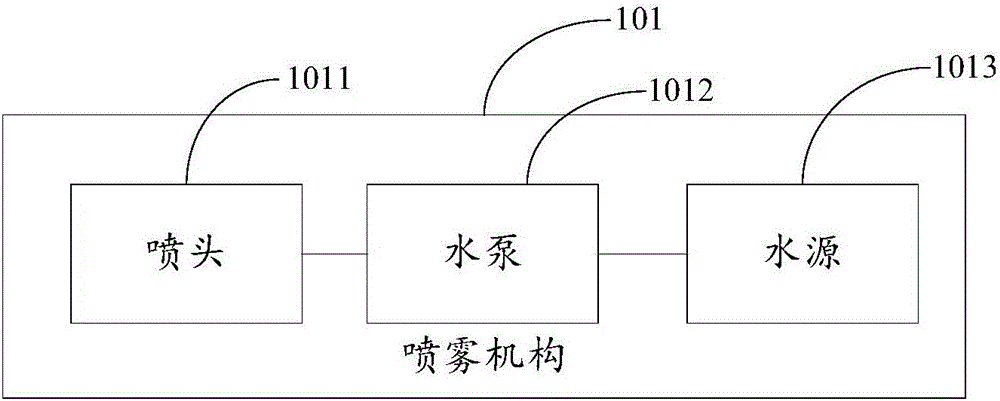

[0070] The dust removal device 100 in this embodiment includes a spray mechanism 101 installed at a preset position under the mine; an air supply mechanism 102 installed at a preset position under the mine; a dust detection mechanism 103 installed at a preset position under the mine; and dust When the dust concentration at the preset position detected by the detection mechanism 103 is greater than the preset concentration, the dust removal control mechanism 104 is used to control the operation of the spray mechanism 101 and the air blowing mechanism 102 .

[0071] In the mining of underground minerals, especially in coal mines, particles are freed in the air under the action of machinery, and the particles contain a large amount of harmful substances, which will enter the body of the staff with the breathing of the staff, thus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com