Dynamic prediction method for wellbore flow in coal-bed gas well

A technology for coalbed methane wells and flow patterns, applied in wellbore/well components, measurement, earthwork drilling and production, etc., can solve the problem of rare flow characteristics of three-phase flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

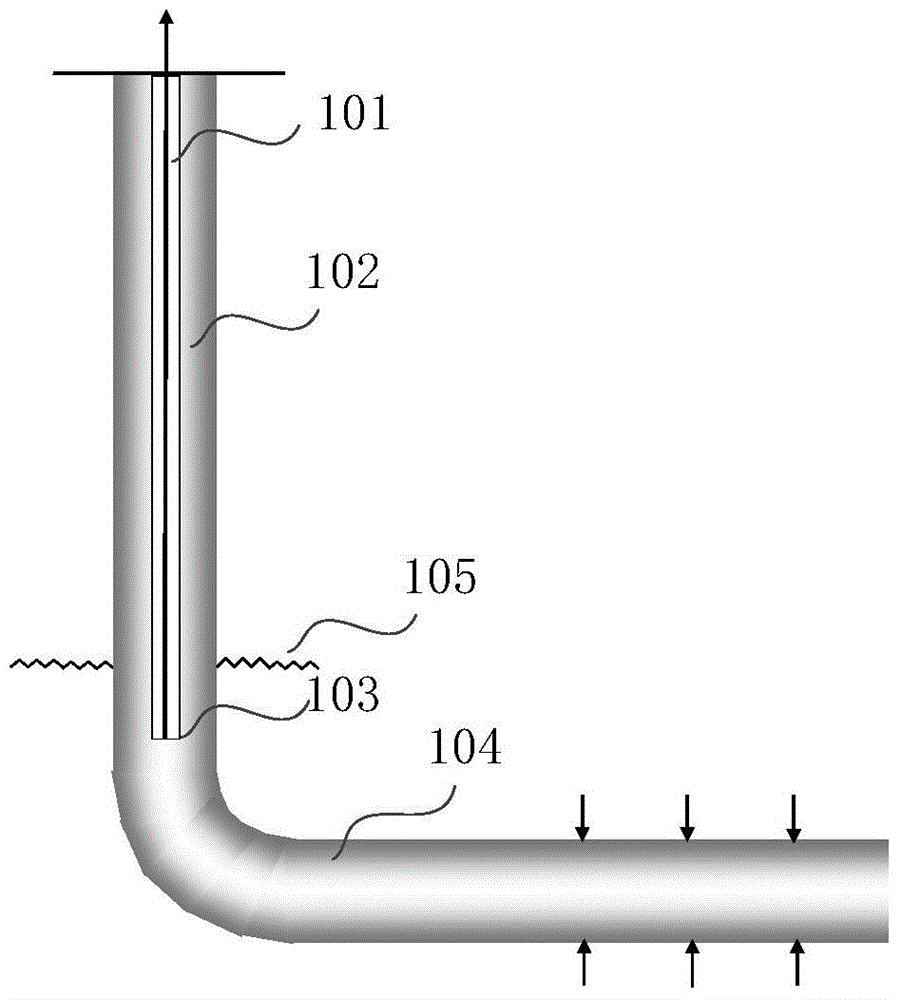

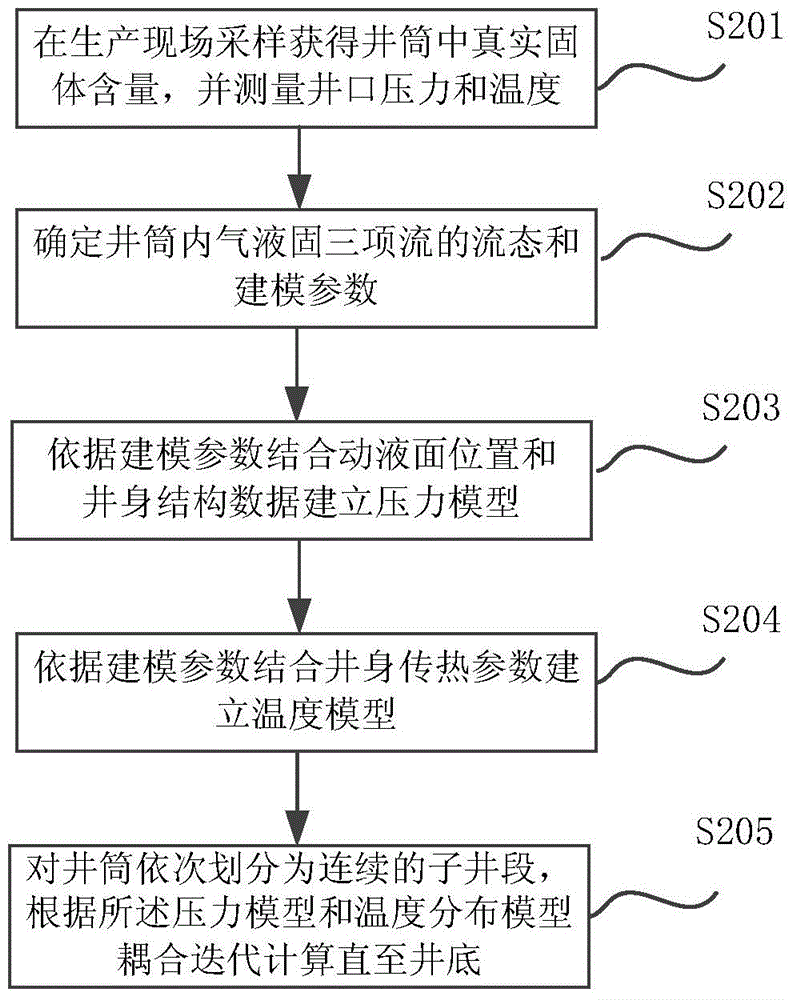

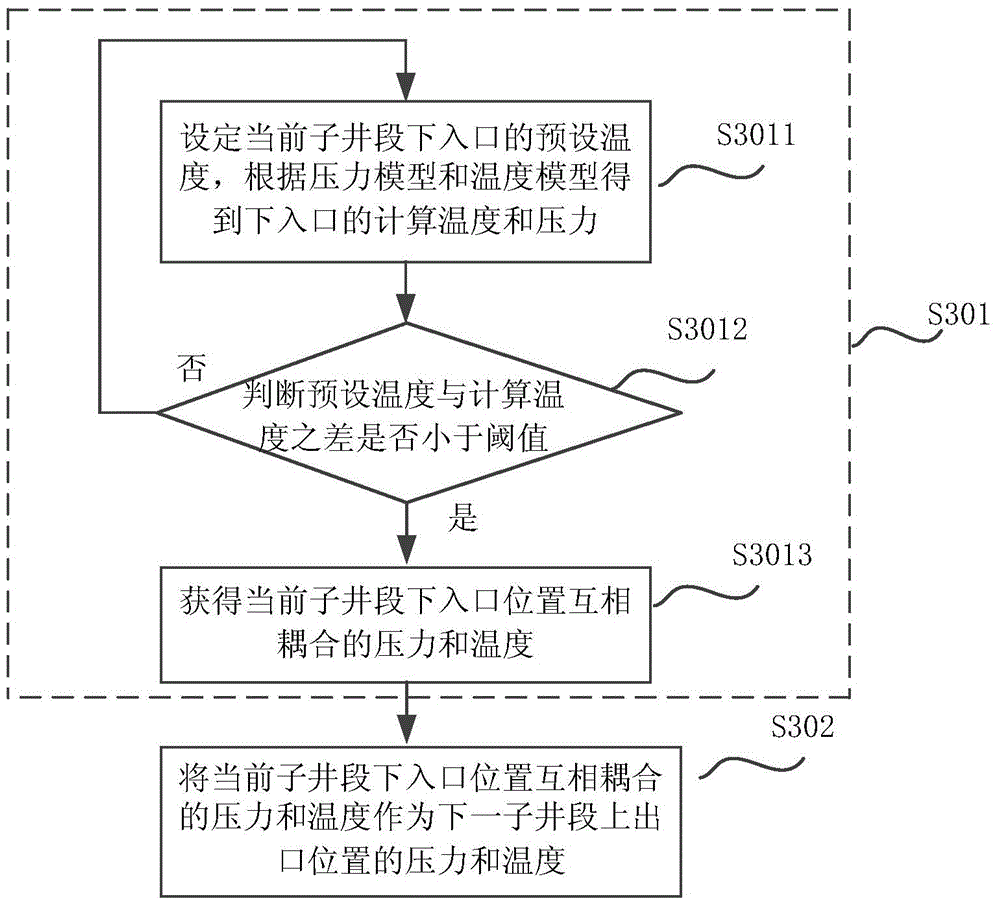

[0053] The invention discloses a method for predicting the flow dynamics of a wellbore of a coalbed methane well. figure 2 A flowchart is shown. The following combination figure 2 The method of this embodiment will be described in detail.

[0054] In step S201, the liquid in the wellbore tubing is sampled to obtain the real solid content H in the wellbore s ;Measure the liquid volume flow and gas volume flow of the wellhead, as well as the temperature and pressure of the wellhead.

[0055] Specifically, water samples were taken from the oil pipes under the production mode of oil pipe water production and casing gas production, the solid phase was coal powder, and the concentration of coal powder was measured from the water samples. If the pulverized coal particles in the water sample taken out are small and most of them can be suspended in the water with very little precipitation, the concentration of the pulverized coal particles in suspension can be measured with a turb...

Embodiment 2

[0203] This embodiment is an example of applying the method of the present invention at the engineering site. The well is a vertical well, and the average volume concentration of pulverized coal measured at the wellhead is 5%, that is, the real solid content H s =5%; the well depth is 1399.49m; the pipe diameter D=139.7-7.72=131.98mm; the casing pressure is 1MPa; the dynamic liquid level height is 806.32m.

[0204] The wellbore data table at the work site is shown in Table 4.

[0205] Table 4

[0206]

[0207] The production data are shown in Table 5.

[0208] table 5

[0209]

[0210] The wellbore heat transfer parameters are shown in Table 6.

[0211] Table 6

[0212] project

[0213] According to the method provided in Example 1, it can be obtained as Figure 6 The pressure distribution of the casing annulus in the wellbore shown, and Figure 7 The temperature distribution in the oil jacket annulus is shown. The bottom hole pressure calculated by us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com