A regenerative heating furnace and its flue gas circulation combustion method

A flue gas circulation and combustion method technology, which is applied in heat treatment furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of uneven temperature of the slab out of the furnace, large degree of incomplete combustion, and large amount of oxidation burning loss. The pipeline and control system are simple, the effect of reducing oxidation and stabilizing combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

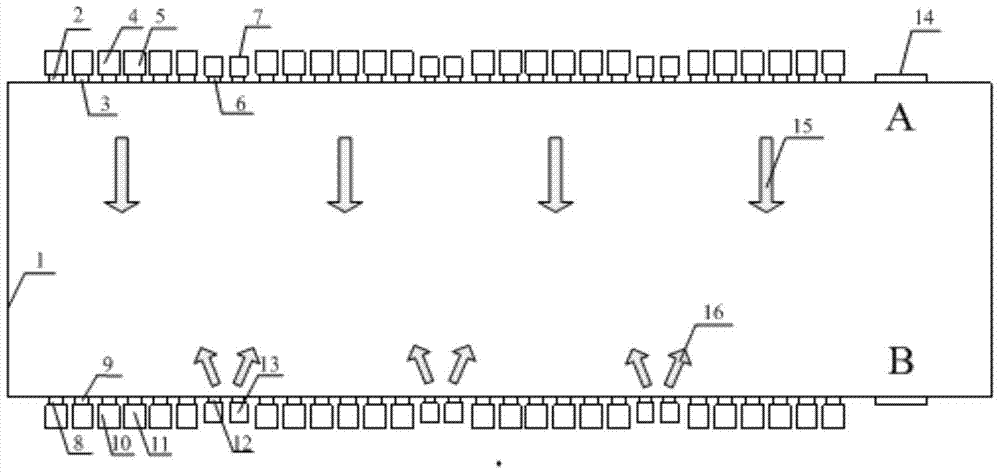

[0023] see figure 1 , the regenerative heating furnace is divided into four heating sections from right to left: preheating section, first heating section, second heating section and soaking section; all heating sections are centralized on the same side; Combustion-supporting air burners 3, 9 and gas burners 2, 8 are arranged symmetrically on the wall; between the heating sections of the conventional regenerative heating furnace, regenerative flue gas auxiliary burners 6 are respectively added to the two side walls of the heating furnace , 12. The flue gas auxiliary burners 6 and 12 on both sides of the furnace are arranged in pairs between each heating section, and the two burners are arranged opposite to the furnace width direction at a certain angle, and are respectively biased towards the adjacent heating sections. Gas burners, combustion-supporting air burners and flue gas auxiliary burners are all provided with gas burner regenerators 4,10, combustion-supporting air bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com