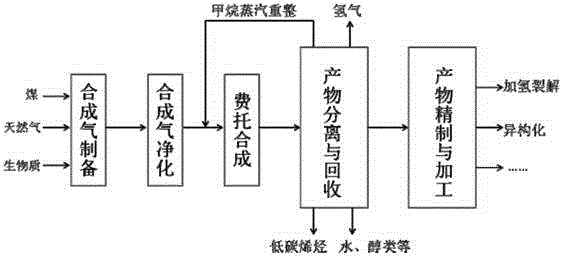

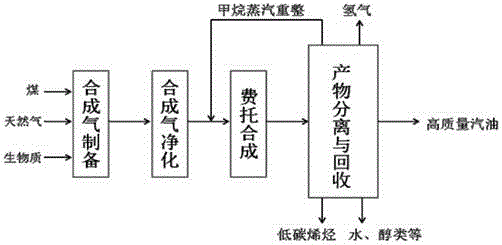

Bifunctional catalyst-based short-process Fischer-Tropsch synthesis novel oil preparation process

A dual-function catalyst, Fischer-Tropsch synthesis technology, applied in the petroleum industry, preparation of liquid hydrocarbon mixtures, inorganic chemistry, etc., can solve problems such as specific applications of catalysts that are not involved, achieve great practicability and economy, and slow down the deactivation rate. , optimize the effect of traditional methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

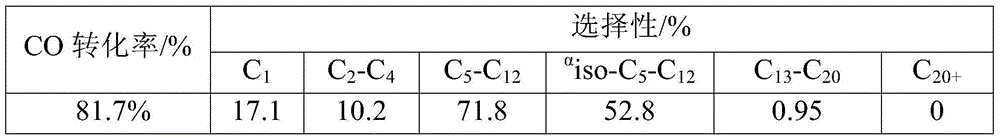

Embodiment 1

[0026] A short-flow Fischer-Tropsch synthetic oil production process based on dual-functional catalysts, including the following steps: (1) Desulfurization and purification of crude synthesis gas produced from coal, natural gas or biomass as raw materials, followed by water-gas shift Response adjusted to H 2 / CO molar ratio of 2-5:1 raw material synthesis gas; (2) The raw material synthesis gas enters the reactor to carry out the Fischer-Tropsch synthesis reaction in the presence of a bifunctional catalyst, and directly obtains a high-octane gasoline component after separation; ( 3) Steam reforming of methane, the tail gas is treated to recover hydrogen and low-carbon hydrocarbons, and the synthetic water is treated with wastewater after removing alcohols; the catalyst selected is Co / HZSM-5 dual-function with embedded structure Catalyst, metal active component Co embedded in HZSM-5 molecular sieve, which was applied to Fischer-Tropsch synthesis reaction. The final reaction re...

Embodiment 2

[0031] Repeat Example 1, its difference is only: select the Co-Zr / HZSM-5 bifunctional catalyst with embedded structure for use, metal active component Co and auxiliary agent Zr are embedded in HZSM-5 molecular sieve, its technological process and Product quality is close to embodiment 1.

Embodiment 3

[0033] Repeat Example 1, the only difference is: select the Co / Hβ bifunctional catalyst with embedded structure, the metal active component Co is embedded in the Hβ molecular sieve, its process flow and product quality are close to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com