High-temperature vulcanized silicone rubber for cold-contracted sleeve and process for high-temperature vulcanized silicone rubber

A high-temperature vulcanization and cold-shrinkable sleeve technology, applied in the field of chemical materials, can solve the problem of low tensile strength at constant elongation, and achieve high tensile strength at constant elongation, low permanent deformation at constant elongation, and elongation at break. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

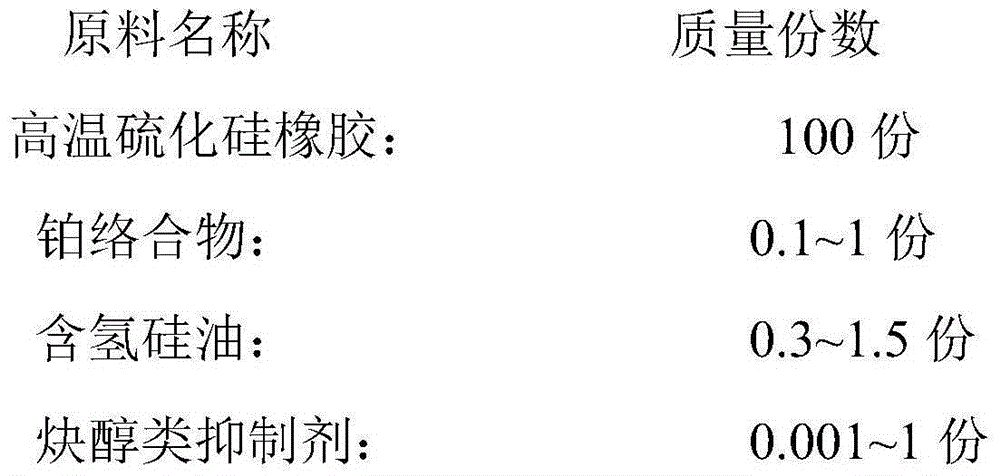

[0027] This embodiment provides a high-temperature vulcanized silicone rubber for cold-shrinkable sleeves, wherein the high-temperature vulcanized silicone rubber for cold-shrinkable sleeves contains the following raw material components and quantities: Silicone raw rubber 1: 12-20 parts, Silicone raw rubber 2: 15-23 parts, Silicone rubber 3: 47-66 parts, Silicone rubber 4: 8-20 parts, Silicone rubber 5: 1-8 parts, Vinyl silicone oil: 0-3 parts, Dimethicone oil: 0 ~5 parts, white carbon black: 28~40 parts, silazane: 2~8 parts, deionized water: 1~4 parts, silane coupling agent: 1.2~5 parts, internal release agent: 0.08~0.3 parts .

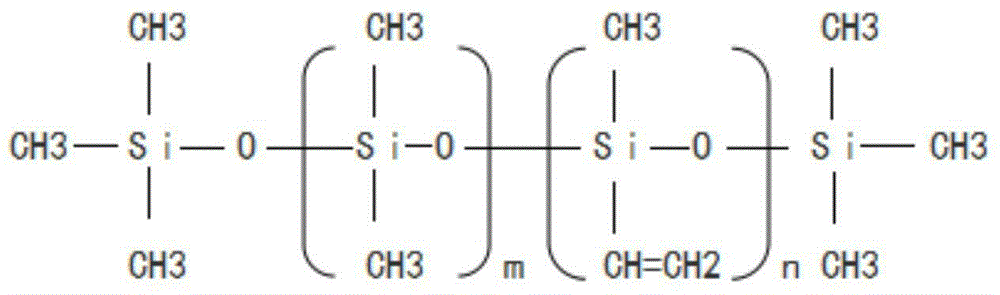

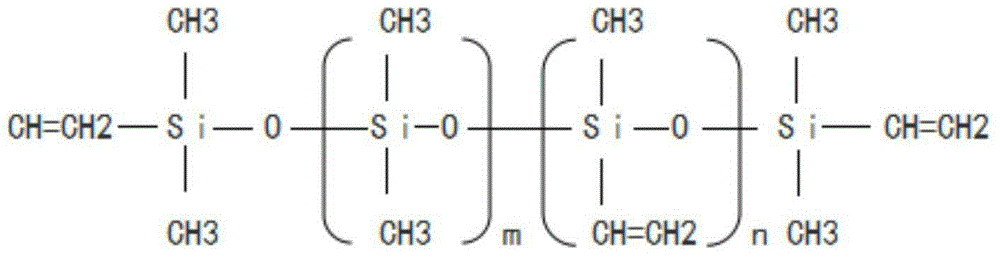

[0028] Among them, raw silicone rubber 1 and raw silicone rubber 2 respectively use methyl-terminated methyl vinyl silicone rubber raw rubber with different vinyl molar contents; their structural formulas are:

[0029]

[0030] Specifically, for raw rubber 1, choose methyl-terminated methyl vinyl silicone rubber with a molecular weight of 550,00...

Embodiment 2

[0046] This embodiment provides a process for preparing the high-temperature vulcanized silicone rubber for the cold shrinkable sleeve described in Example 1, wherein the process comprises the following steps:

[0047] First, step A: batching and mixing: batching is carried out according to the raw material components and quantities in Example 1. After the ingredients are prepared, silicone raw rubber 1, silicon raw rubber 2, silicon raw rubber 3, silicon Raw rubber 4, silicone raw rubber 5, vinyl silicone oil and / or dimethyl silicone oil, white carbon black, silazane, deionized water, silane coupling agent, and internal mold release agent are added to the kneader and kneaded into a group Finally, close the kneader, and leave it at room temperature for 8 hours, and leave it for use.

[0048] Then, perform step B: that is, high-temperature vacuum mixing: put the agglomerated material into a kneader, and then knead at a high temperature for 3 hours, wherein the vacuum degree of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com