Purification method of chromatographic grade n-propanol

A purification method and technology for n-propanol, which are applied in chemical instruments and methods, separation/purification of hydroxyl compounds, preparation of organic compounds, etc. The production process is simple, the operation is stable, and the yield is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

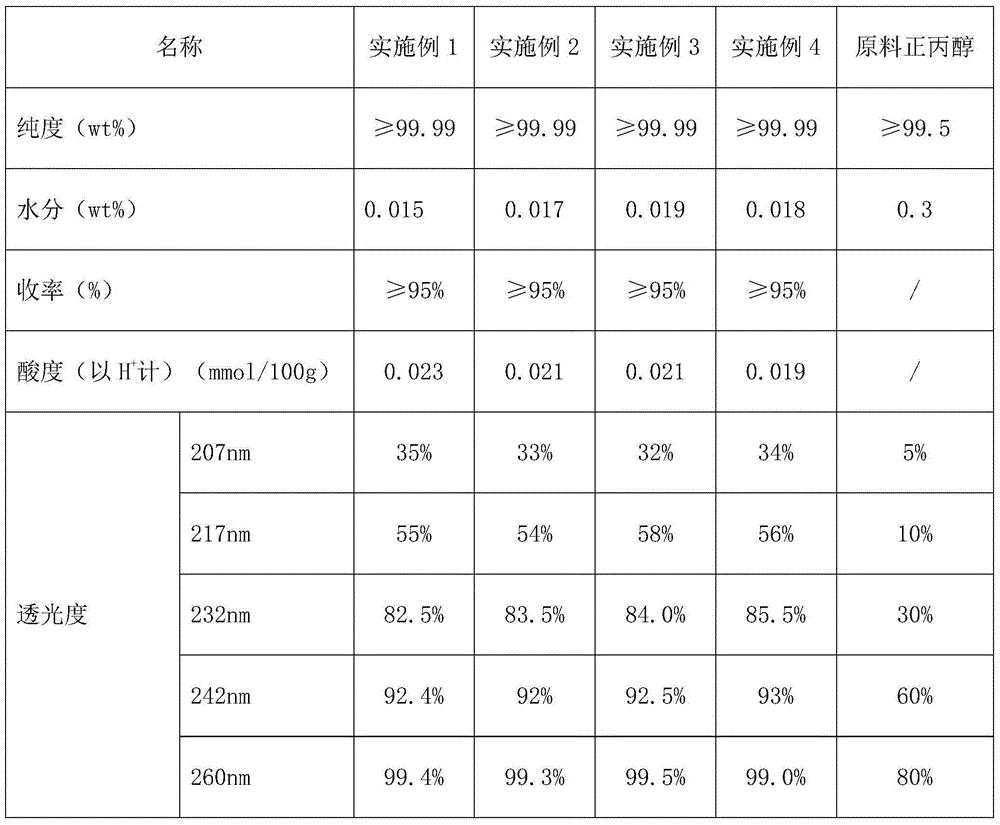

Examples

Embodiment 1

[0020] The purification method of chromatographic grade n-propanol comprises the steps:

[0021] a. get the raw material n-propanol with a purity of 99.5% (wt), add sodium carbonate to adjust the pH of the solution to 7, and shake to make the acidic impurities in the sodium carbonate and the raw material n-propanol fully react to generate salt precipitates ; Static layering, discard the water layer and precipitate, filter the organic layer, retain the filtrate.

[0022] b. Adsorption:

[0023] 1. The above-mentioned filtrate is passed into the adsorbent column that particle diameter is 50 order 3A molecular sieves with the speed of 0.5 column volume / hour, further removes the moisture in the organic layer; After adsorption, n-propanol water content is controlled at≤0.03% In this step, molecular sieves are used to remove the moisture in the extracted n-propanol. If the moisture content is > 0.03%, the molecular sieve needs to be replaced before continuing the molecular sieve ad...

Embodiment 2

[0028] The purification method of chromatographic grade n-propanol comprises the steps:

[0029] a. get raw material n-propanol with a purity of 99.5% (wt), add potassium hydroxide to adjust the pH of the solution to 8, and shake to make potassium hydroxide fully react with the acidic impurities in the raw material n-propanol to generate salts Precipitate; leave to separate layers, discard the water layer and precipitate, filter the organic layer, and keep the filtrate.

[0030] b. Adsorption:

[0031] 1. The above-mentioned filtrate is passed into the adsorbent column that particle diameter is 20 order 3A molecular sieves with the speed of 30 column volumes / hour, further removes the moisture in the organic layer; After adsorption, n-propanol water content is controlled at≤0.03% In this step, molecular sieves are used to remove the moisture in the extracted n-propanol. If the moisture content is > 0.03%, the molecular sieve needs to be replaced before continuing the molecular...

Embodiment 3

[0036] The purification method of chromatographic grade n-propanol comprises the steps:

[0037] a. get the raw material n-propanol with a purity of 99.5% (wt), add sodium oxide to adjust the pH of the solution to 7.5, and shake to make the sodium oxide fully react with the acidic impurities in the raw material n-propanol to generate salt precipitates ; Static layering, discard the water layer and precipitate, filter the organic layer, retain the filtrate.

[0038] b. Adsorption:

[0039] 1. above-mentioned filtrate is passed into the adsorbent column that particle diameter is 100 mesh molecular sieves with the speed of 15 column volumes / hour, further removes the moisture in the organic layer; After adsorption, n-propanol water content is controlled at≤0.03%; In this step, the molecular sieve is used to remove the moisture in the extracted n-propanol. If the moisture content is >0.03%, the molecular sieve needs to be replaced before continuing the molecular sieve adsorption t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com