Chelated calcium fertilizer prepared from oyster shell, and preparation method and application thereof

A technology for chelating calcium fertilizers and oyster shells, applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problems of inability to use drip irrigation fertilizer, calcium is not easily soluble in water, etc., to improve appearance quality, increase value, and increase crop resistance. Disease and disease resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

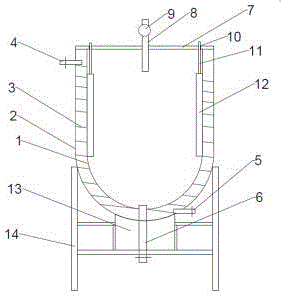

Method used

Image

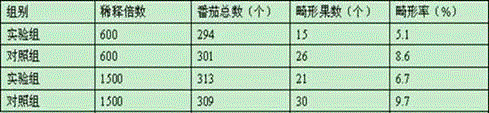

Examples

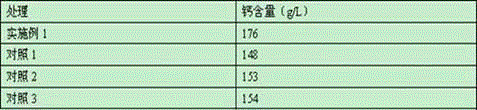

Embodiment 1

[0048] A kind of preparation method of the chelated calcium fertilizer that utilizes oyster shell to prepare comprises the steps:

[0049] A. Pretreatment: Rinse the oyster shells with clean water, soak them in dilute hydrochloric acid solution with a mass fraction of 1% for 4 hours, then dry the soaked oyster shells at 110°C, and crush them to 35 meshes to obtain oyster shell powder;

[0050] B. Acid hydrolysis: 5 parts by weight of concentrated hydrochloric acid with a mass fraction of 20% and 1.5 parts by weight of the oyster shell powder are placed in a reactor, reacted for 2 hours under stirring conditions, and the reactants are separated into solid and liquid after the reaction , the obtained liquid is the first reaction liquid;

[0051] C, chelation: at 15°C, add the first reaction solution into the chelation tank, add dropwise the sugar alcohol accounting for 15% of the weight of the oyster shell powder, drop it in 0.5h, and continue the reaction for 0.5h to obtain T...

Embodiment 2

[0056] A kind of preparation method of the chelated calcium fertilizer that utilizes oyster shell to prepare comprises the steps:

[0057] A. Pretreatment: After rinsing the oyster shells with clean water, soak them in a dilute hydrochloric acid solution with a mass fraction of 1% for 4 hours, then dry the soaked oyster shells at 110°C, and crush them to 50 meshes to obtain oyster shell powder;

[0058] B. Acid hydrolysis: 4 parts by weight of concentrated hydrochloric acid with a mass fraction of 25% and 1.6 parts by weight of the oyster shell powder are placed in a reactor, and reacted for 3 hours under stirring conditions. After the reaction is completed, the reactants are solid-liquid Separation, the obtained liquid is the first reaction liquid;

[0059] C. Chelation: at 25°C, add the first reaction solution into the chelation tank, then add dropwise the sugar alcohol accounting for 20% of the weight of the oyster shell powder, drop it in 0.5h, and continue the reaction f...

Embodiment 3

[0066] A kind of preparation method of the chelated calcium fertilizer that utilizes oyster shell to prepare comprises the steps:

[0067] A. Pretreatment: After rinsing the oyster shells with clean water, soak them in a dilute hydrochloric acid solution with a mass fraction of 1% for 4 hours, then dry the soaked oyster shells at 110°C, and crush them to 80 meshes to obtain oyster shell powder;

[0068] B. Acid hydrolysis: 3.33 parts by weight of concentrated hydrochloric acid with a mass fraction of 30% and 2 parts by weight of the oyster shell powder are placed in a reactor, and reacted for 4 hours under stirring conditions. After the reaction is completed, the reactant is solid-liquid Separation, the obtained liquid is the first reaction liquid;

[0069] C. Chelation: at 35°C, add the first reaction solution into the chelation tank, then add dropwise the sugar alcohol accounting for 30% of the weight of the oyster shell powder, drop it in 0.5h, and continue the reaction fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com