Water collecting component

A water collection and water collection tank technology, which is applied in the direction of ion exchange water/sewage treatment, etc., can solve the problems of poor maintainability and achieve the effects of long service life, good maintainability, and uniform water flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

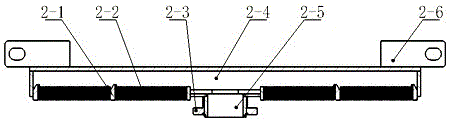

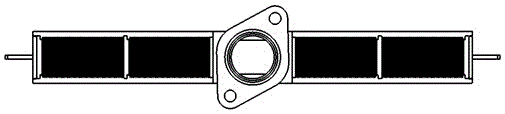

[0017] It is composed of a sump, an outlet pipe and a shuttle flange for placing the sump; the sump is composed of a grid mounting seat, a grid unit, a baffle and a connection block of the sump; several grids are stacked along the grid mounting seat, and the baffle It is used to press the grid piece tightly and prevent the grid piece from falling off; the grid piece has a number of convex points, which can ensure the size of the flow gap on the water collection tank after pressing; the water collection tank is connected to the water collection tank through the shuttle flange of the grid piece seat The block is installed on the bottom plate of the water treatment equipment.

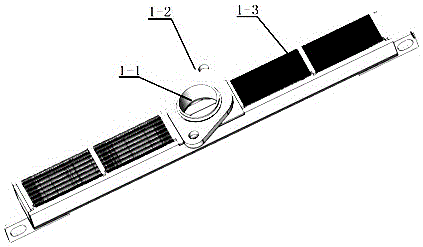

[0018] The water collecting element is composed of a water collecting tank 1-3, a water outlet pipe 1-1 and a shuttle-shaped flange 1-2 for placing the water collecting tank. The water collection tank 1-3 is composed of a grid sheet mounting base 2-4, a grid sheet unit 2-2, a baffle plate 2-1 and a water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com