Graphene material powder and preparation method

A graphene and powder technology, applied in the field of graphene material powder and preparation, can solve the problems of difficulty in restoring the original state, unfavorable application, large volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Compared with the prior art, the graphene material powder provided by the present invention is composed of a graphene material and a polymer, and the surface of the graphene material is evenly covered with a polymer, so that the adjacent graphene materials are evenly spaced. There are polymers that form a barrier. Therefore, the graphene materials in the graphene material powder of the present invention are not entangled with each other, do not fold back when subjected to external pressure, and are very easy to disperse in a solvent. Preferably, the graphene material powder can also include a plurality of graphene material assemblies with special structural design, the graphene material assembly is a nearly spherical structure or a granular structure, and the particle size range is 10 to 300 μm. The graphite Apparent density of olefin material powder ≥ 0.02g / cm 3 . Preferably, the apparent density of the graphene material powder is 0.05g / cm 3 ~0.2g / cm 3 . Since the...

Embodiment 1

[0064] Get 100Kg mass concentration and be 0.1% graphene material slurry (solvent is water), be 1:5 to take by weighing 0.5Kg polyvinyl alcohol (PVA) to join above-mentioned graphene material slurry according to the mass ratio of graphene material and polymer The intermediate slurry was prepared in the middle; the intermediate slurry was spray-dried, the inlet air temperature was 270°C, and the outlet temperature was 150°C. Obtain graphene material powder.

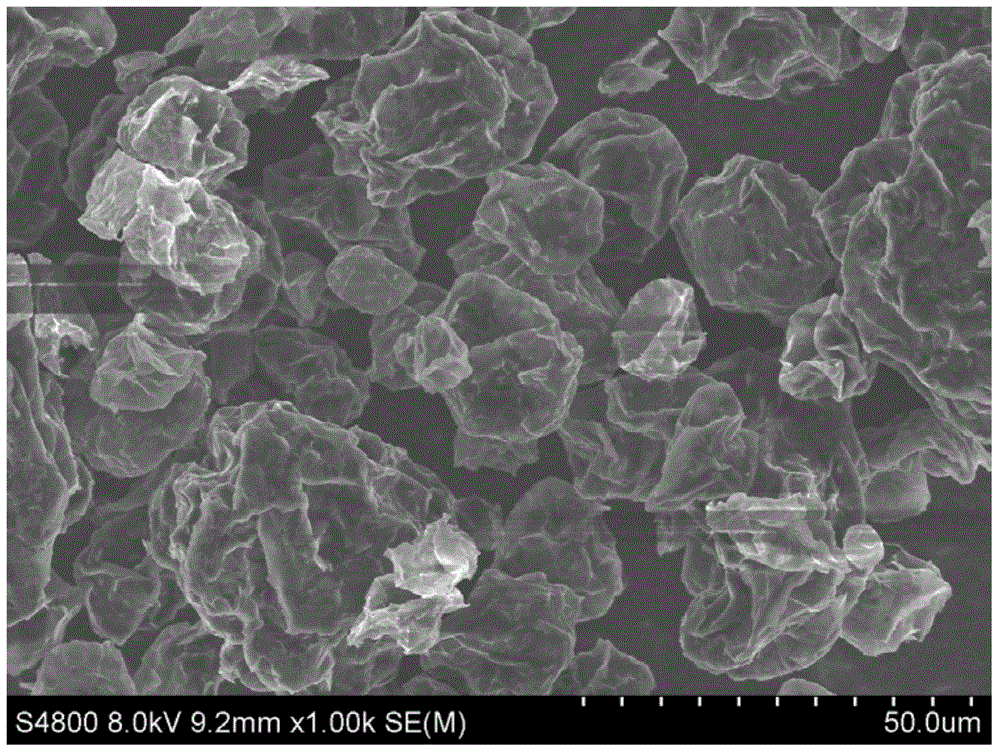

[0065] figure 1 For the scanning electron microscope (SEM) figure of the graphene material powder that the embodiment of the present invention 1 obtains, by figure 1 It can be seen that the particle size range of the graphene material powder obtained in Example 1 of the present invention is 10 μm to 50 μm.

Embodiment 2

[0067] Get 100Kg mass concentration and be 0.1% graphene material slurry (solvent is water), be 1:5 to take by weighing 0.5Kg polyvinyl alcohol (PVA) to join above-mentioned graphene material slurry according to the mass ratio of graphene material and polymer The intermediate slurry is prepared in an intermediate slurry; the intermediate slurry is slowly added to ether under stirring until the graphene material and polyvinyl alcohol (PVA) are completely precipitated, then filtered with suction, and treated in an oven at 30-200°C until the solvent is completely evaporated That's it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com