Fixture structure

A fixture and workpiece technology, applied in the field of fixture structure, can solve the problems of increasing tool processing cost, wasting calibration time, and low processing efficiency, and achieve the effects of saving calibration time, reducing processing cost, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

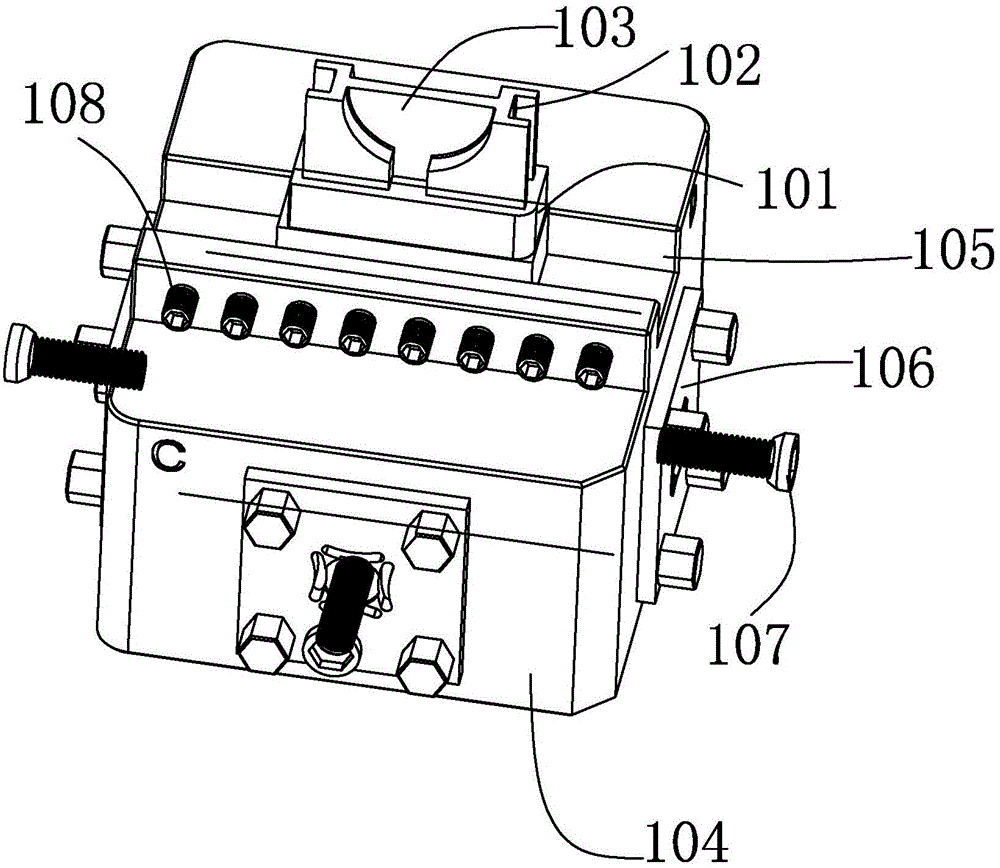

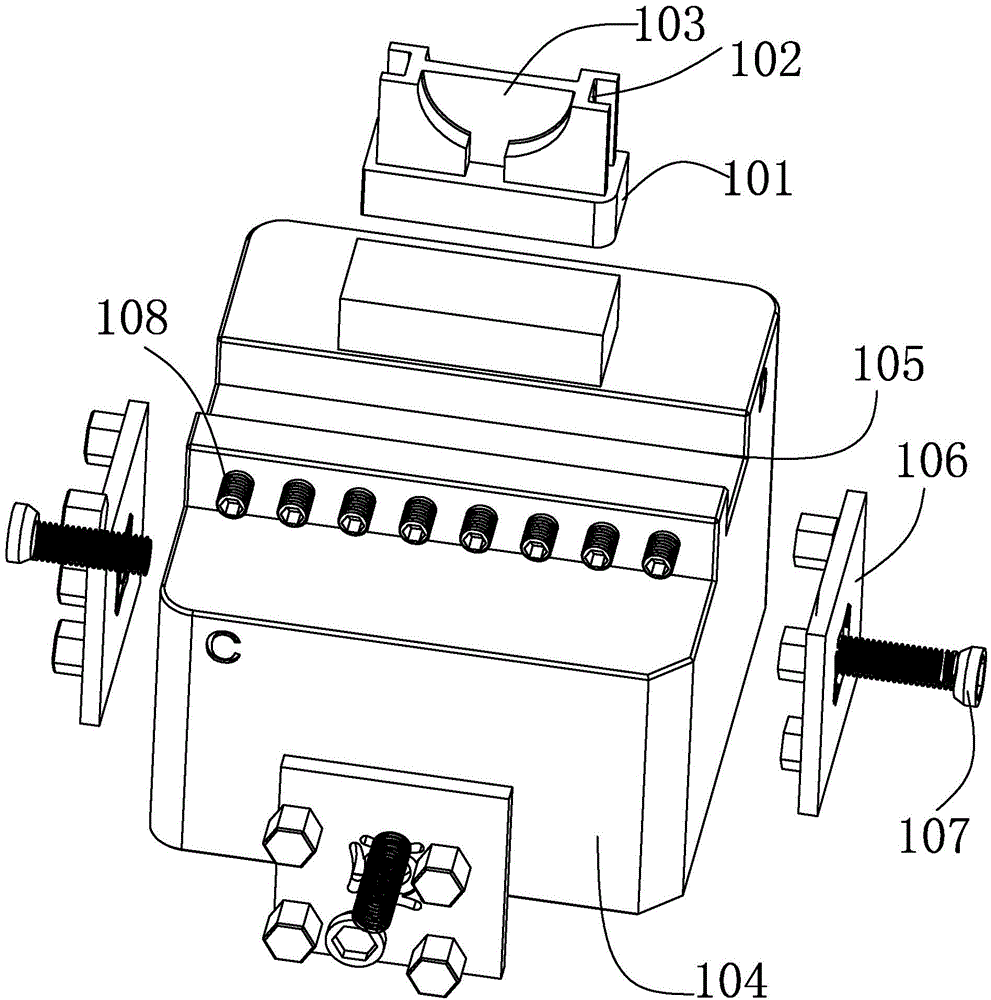

[0018] Please refer to figure 2 , image 3 , figure 2 It is a schematic diagram of the first processing state of a preferred embodiment of the centering fixture structure of the present invention, image 3 shown as figure 2 Schematic diagram of the breakdown structure.

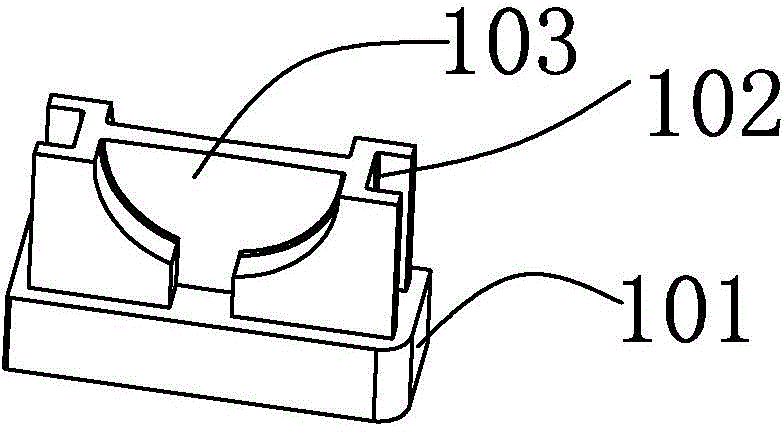

[0019] The fixture structure provided by the present invention clamps a stepped workpiece 101 with a rectangular groove 102 and a semicircular groove 103 ( Figure 2-5 In order to facilitate the understanding of the processed parts of the workpiece 101, the workpiece 101 is shown as the processed workpiece 101), and the fixture structure is arranged on a CNC milling machine, and the structure includes:

[0020] The base 104 has a top surface, a bottom surface, a left side, a right side, a front surface and a back surface, the top surface is provided with a workpiece groove 105, and the workpiece 101 is clamped in the workpiece groove 105;

[0021] Spacers 106, which are respectively arranged on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com