Overhead welding and cutting equipment

A technology of cutting equipment and self-propagating welding, which is applied in welding equipment, aluminothermic welding equipment, metal processing equipment, etc., can solve problems such as troubles, and achieve the effects of safe operation, high portability, and shortened preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to deepen the understanding of the present invention, the present invention will be further described below with reference to the accompanying drawings and embodiments. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

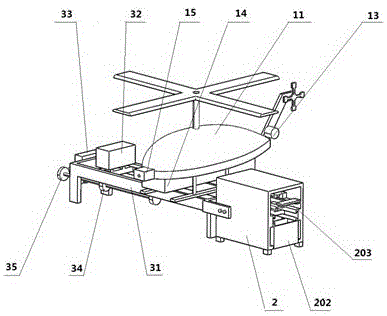

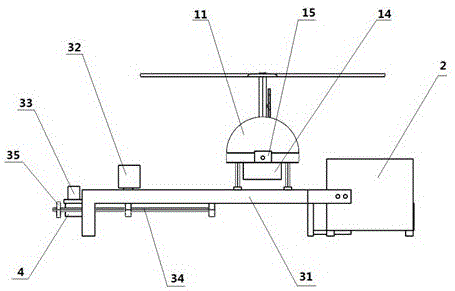

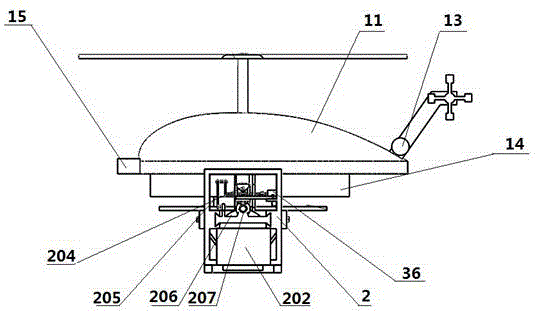

[0050] like Figure 1~20 , a UAV high-altitude welding and cutting equipment including UAV, UAV auxiliary part, self-propagating reaction welding / cutting part and frame and counterweight part;

[0051] The UAV auxiliary part includes an airborne environment monitoring module 13, an airborne controller 14 and an airborne camera 15 installed on the single-rotor UAV 11 or the multi-rotor UAV 12;

[0052] The self-propagating reaction welding / cutting part includes a self-propagating reaction box 2, and the self-propagating reaction box 2 includes a self-propagating reaction box body 201. The self-propagating reaction box camera 204 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com