Two-stage crusher

A crusher and crushing cavity technology, applied in grain processing, etc., can solve the problems of easy clogging of materials, low output, and not too large feeding particle size, and achieve the effect of not easy to block, uniform product particle size and large crushing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

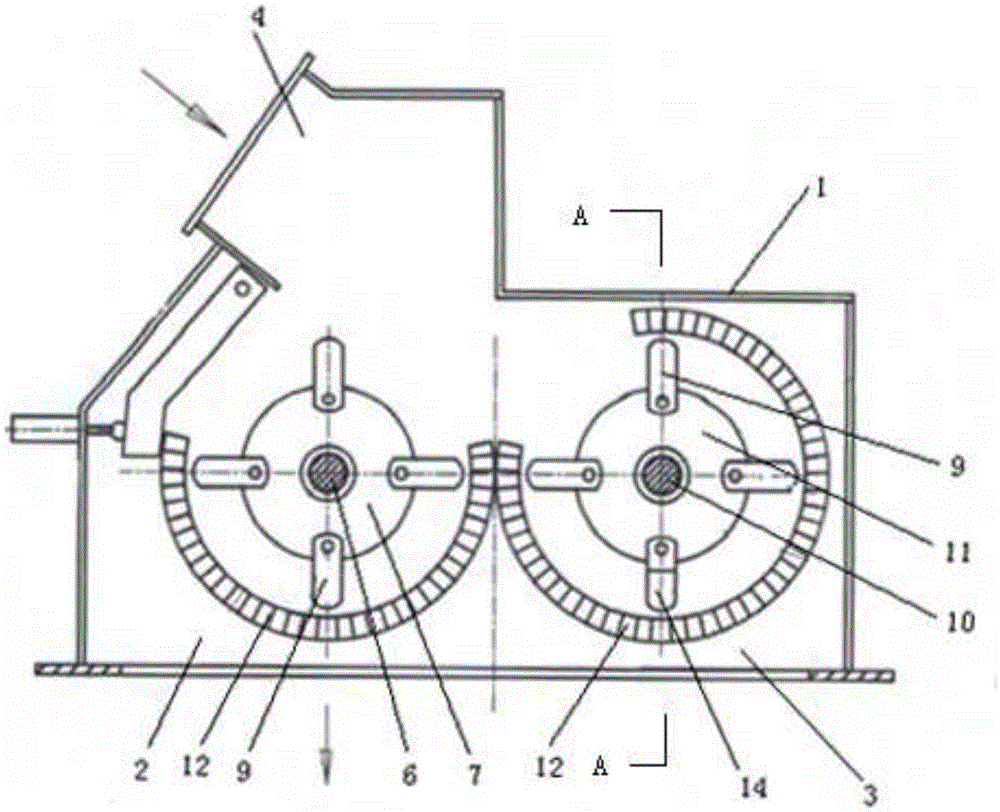

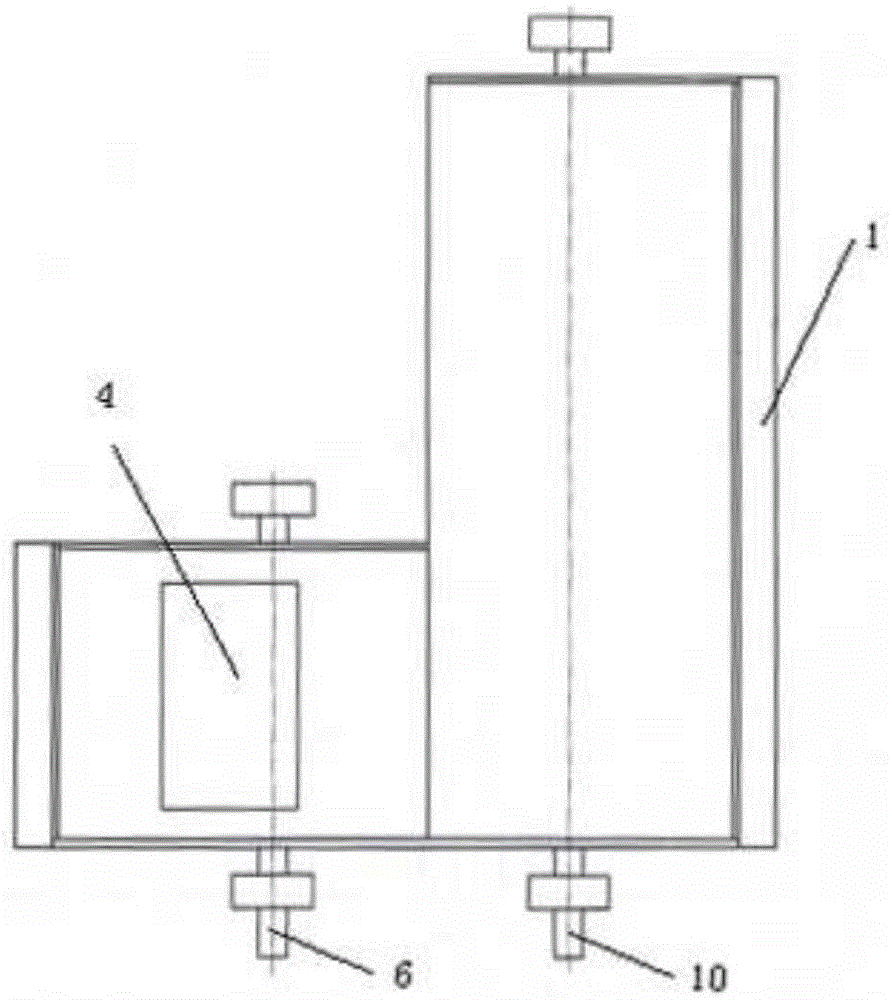

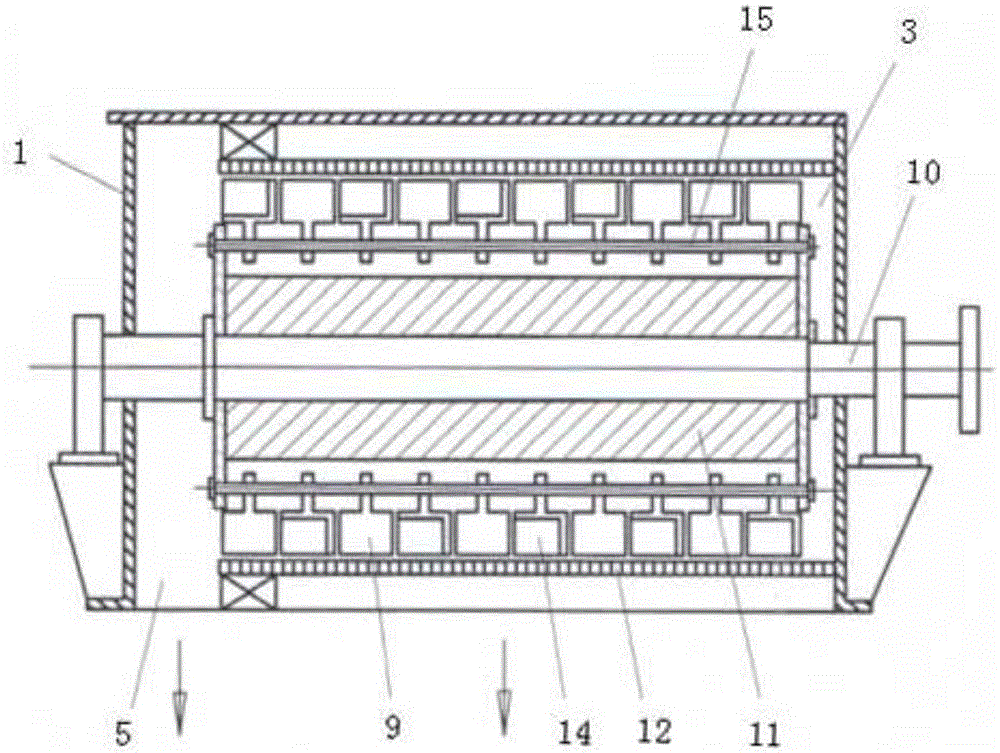

[0035] See attached figure 1 to attach image 3 , with figure 1 to attach image 3 A specific embodiment of a two-stage crusher is provided, wherein, the attached figure 1 For the front view of the double-stage crusher, attached figure 2 It is the top view of the double-stage crusher; image 3 It is the A-A sectional view of the double-stage crusher.

[0036] as attached figure 1 to attach image 3 As shown, the double-stage crusher includes a casing 1. A first crushing chamber 2 and a second crushing chamber 3 are arranged in the casing 1. The first crushing chamber 2 and the second crushing chamber 3 are connected and distributed in the casing 1. On both sides, the first crushing chamber 2 is used to provide a coarse crushing place for materials, and the second crushing chamber 3 is used to provide a fine crushing place for materials.

[0037] The first crushing chamber 2 is provided with a material inlet 4, and the material inlet 4 is used for inputting materials t...

Embodiment 2

[0058] See attached Figure 4 , with Figure 4 Another specific embodiment of the double-stage crusher is provided, wherein, the attached Figure 4 It is the front view of the double-stage crusher.

[0059] as attached Figure 4 As shown, a blow bar 8 is installed on the first rotor 7 , and a hammer head 9 and a material transfer hammer head 14 are installed on the second rotor 11 .

Embodiment 3

[0061] See attached Figure 5 And attached Figure 6 , with Figure 5 And attached Figure 6 Another embodiment of the double-stage crusher of the present invention is provided, wherein the attached Figure 5 For the front view of the double-stage crusher, attached Figure 6 It is a B-B sectional view of the double-stage crusher.

[0062] as attached Figure 5 And attached Figure 6 As shown, a blow bar 8 is installed on the first rotor 7 , and a blow bar 8 and a material moving blow bar 13 are installed on the second rotor 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com