Microspheres with high fluorescence intensity and preparation method for microspheres

A technology of fluorescence intensity and microspheres, which is applied in the preparation of microspheres and high fluorescence intensity microspheres, can solve the problems of low quantum yield, complicated preparation process, difficulty in obtaining quantum dot fluorescent microspheres, etc., and achieve fluorescence intensity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

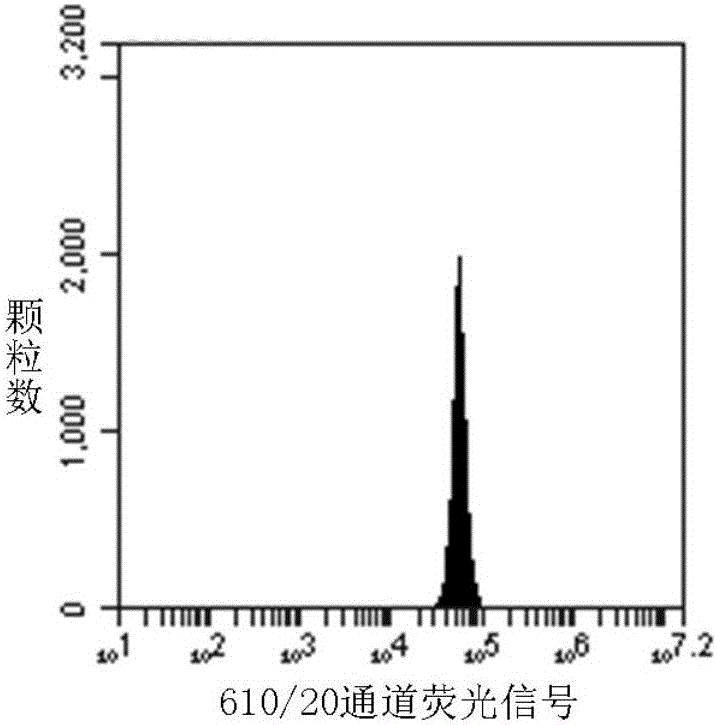

Embodiment 1

[0044] Step 1. Weigh 1 portion of 6.85 mg polystyrene mesoporous microspheres with a pore size of 30 nm on a precision balance, and add it to a 2 mL centrifuge tube;

[0045] Step 2. Weigh 40 mg polystearyl maleic anhydride (PMAO, Mn ~ 30000-50000), dissolve it in 1 mL chloroform, and set aside;

[0046] Step 3. Preparation of alkaline aqueous solution: absorb 200 μL of 1M sodium hydroxide aqueous solution, add it to 4 mL of ultrapure water, and store in a 10 mL glass bottle;

[0047] Step 4, take 120 μL of LCdSe / ZnS dispersion (n-hexane dispersion, 30 μM) in a 500 μL centrifuge tube, add 200 μL of ethanol for flocculation;

[0048] Step 5, centrifuging the quantum dot ethanol mixture in step 4 (3min, 8000rpm), pouring the supernatant after centrifugation;

[0049] Step 6. Volatilize the residual ethanol on the surface of the quantum dot particles obtained in step 5 at room temperature, and then redisperse the quantum dots in 100 μL of chloroform;

[0050] Step 7. Add 50 μL ...

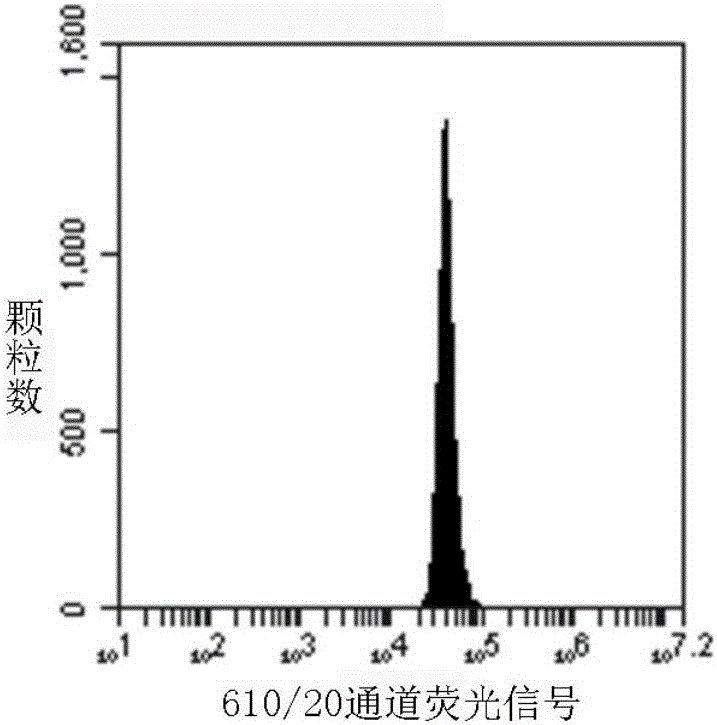

Embodiment 2

[0058] Step 1. Weigh 1 portion of 6.85 mg polystyrene mesoporous microspheres with a pore size of 30 nm on a precision balance, and pour it into a 2 mL centrifuge tube;

[0059] Step 2. Weigh 40 mg of poly(styrene-co-maleic anhydride) (PSMA, Mn~1700), dissolve it in 1 mL of chloroform, and set aside;

[0060] Step 3. Preparation of alkaline aqueous solution: absorb 200 μL of 1M sodium hydroxide aqueous solution, add it to 4 mL of ultrapure water, and store in a 10 mL glass bottle;

[0061] Step 4, take 120 μL of LCdSe / ZnS dispersion (n-hexane dispersion, 30 μM) in a 500 μL centrifuge tube, add 200 μL of ethanol for flocculation;

[0062] Step 5, centrifuging the quantum dot ethanol mixture in step 4 (3min, 8000rpm), pouring the supernatant after centrifugation;

[0063] Step 6. Volatilize the residual ethanol on the surface of the quantum dot particles obtained in step 5 at room temperature, and then redisperse the quantum dots in 100 μL of chloroform;

[0064] Step 7. Add 5...

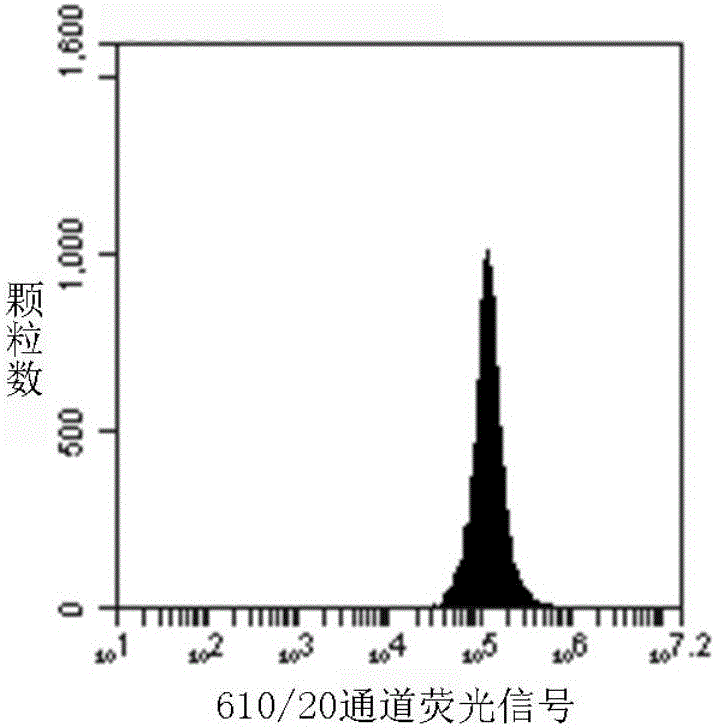

Embodiment 3

[0072] Step 1. Weigh 1 part of 1.37 mg polystyrene mesoporous microspheres with a pore size of 30 nm on a precision balance, and add it to a 2 mL centrifuge tube;

[0073] Step 2, take 24μL of LCdSe / ZnS dispersion (n-hexane, 30μM) in a 500μL centrifuge tube, add 50uL of ethanol for flocculation;

[0074] Step 3, centrifuging the quantum dot ethanol mixture in step 2 (3min, 8000rpm), pouring the supernatant after centrifugation;

[0075] Step 4. Volatilize the residual ethanol on the surface of the quantum dot particles obtained in step 3 at room temperature, and then redisperse the quantum dots in 30 μL of chloroform;

[0076] Step 5. Add 0.4 mg of polystearyl maleic anhydride to the quantum dot chloroform dispersion obtained in step 4, and ultrasonically disperse to make the mixture uniform;

[0077] Step 6. Add 30 μL of the quantum dot chloroform dispersion obtained in step 5 to the weighed 1.37 mg polystyrene microspheres, so that the polystyrene particles are completely i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com