A barrier liquid distributor

A technology of barrier liquid and distributor, which is applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve the problems of fatigue damage of barrier liquid distributor, fatigue damage of barrier liquid distributor, and low service life, etc. Achieve the effect of solving the problem of fatigue damage, improving the safe operation cycle and prolonging the fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

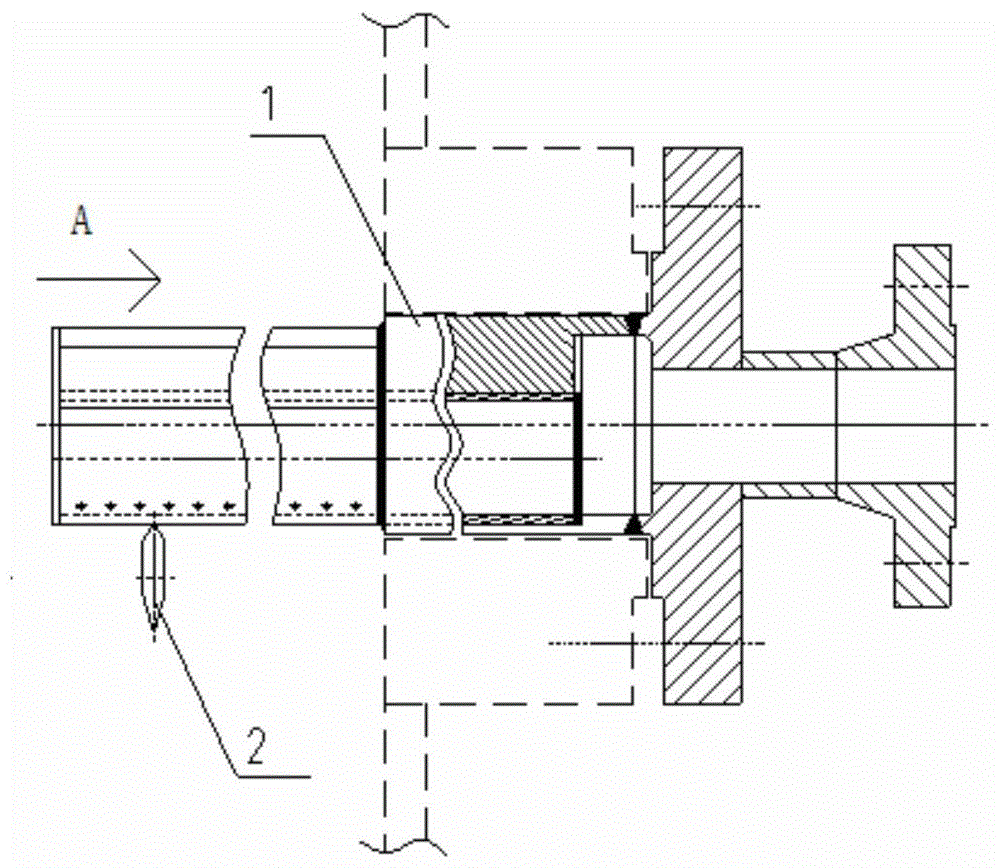

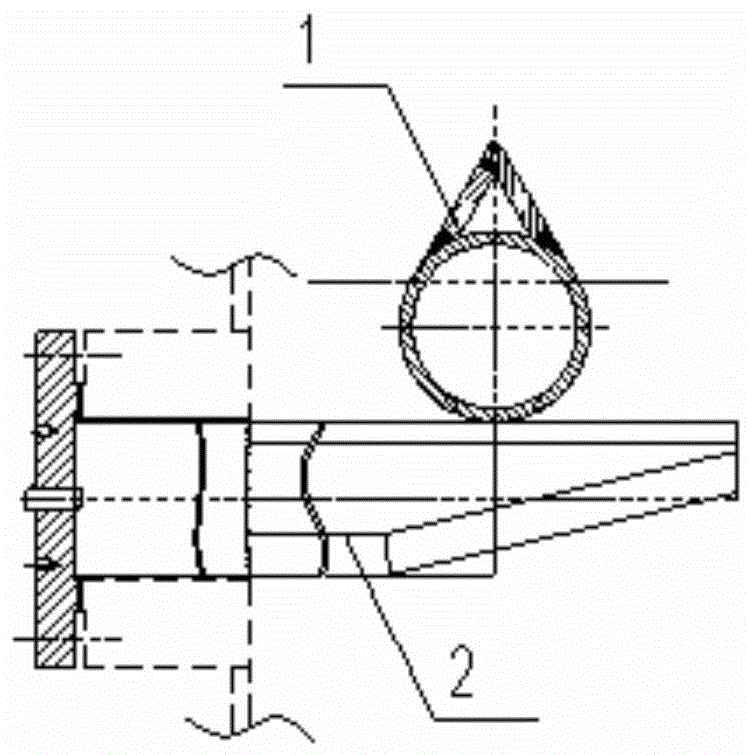

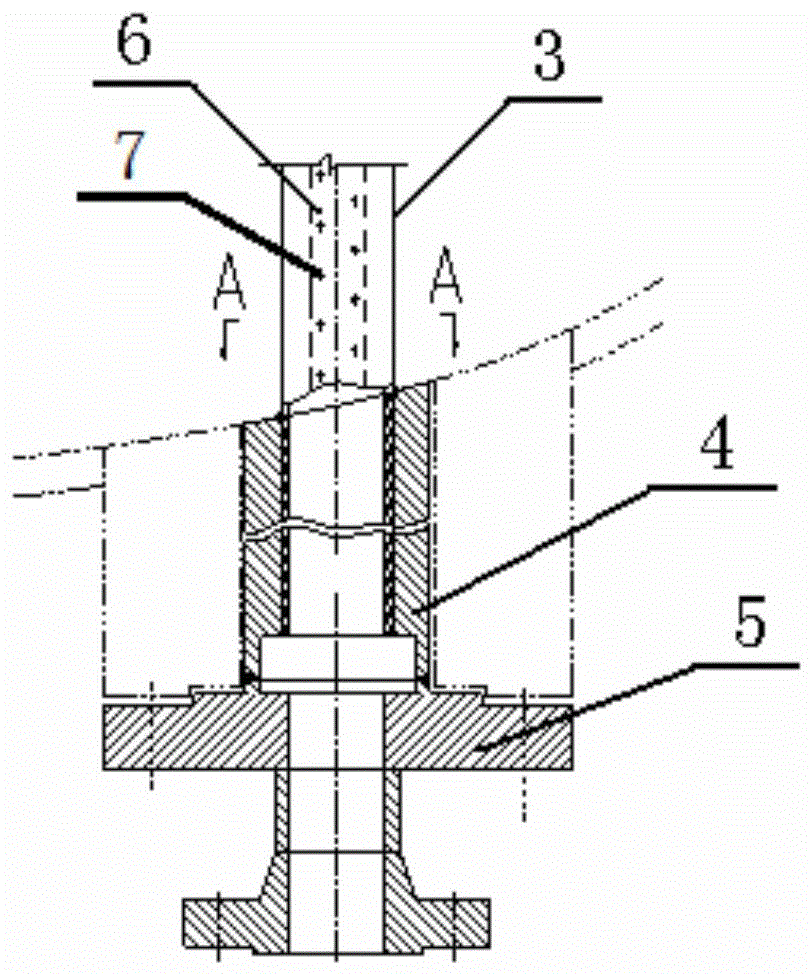

[0034] Such as Figure 1a , Figure 1b , Figure 2a , Figure 2b , image 3 , Figure 4a , Figure 4b , Figure 5 As shown, a barrier liquid distributor includes a barrier liquid distribution pipe 1 and a distribution pipe support block 2; the barrier liquid distribution pipe 1 is a structure with one end fixedly supported and one end simply supported along the vertical and horizontal directions; the barrier liquid The distribution pipe 1 is inserted into the pressure vessel, and one end of the barrier liquid distribution pipe 1 partially overlaps with the distribution pipe support block 2 along the vertical direction to form a support relationship.

[0035] The barrier liquid distribution pipe 1 includes a liquid distribution pipe 3, a distribution pipe plug 4, a distribution pipe flange 5 and a dust-proof baffle 6;

[0036] One end of the distribution pipe plug 4 is an eccentric circular sleeve structure, and the other end is a concentric circular sleeve structure. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com