Caisson gravity type wharf structure

A technology of gravity wharf and caisson, which is applied in the field of wharf structure, can solve the problems of large earth pressure, structural force, structural stability limitation, and inadaptability to large wharf structure selection of caisson gravity wharf structure, so as to reduce uneven settlement , Reduce the base stress, the effect of high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

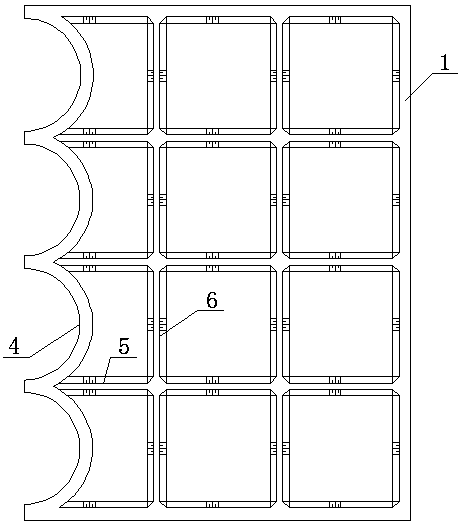

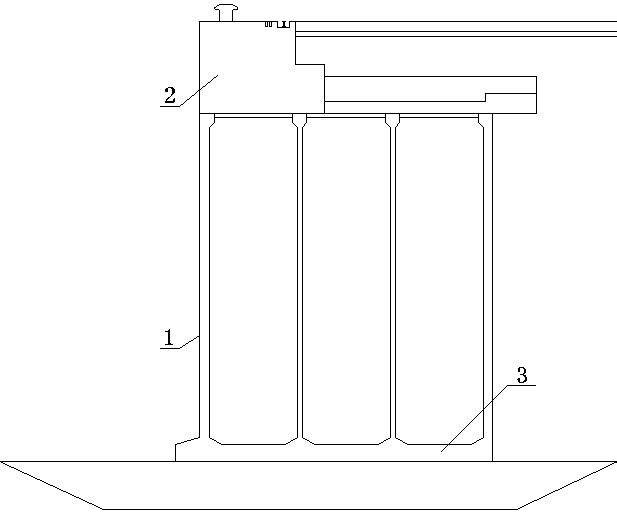

[0019] like figure 1 and figure 2 As shown, a caisson gravity type wharf structure includes a caisson body 1, a parapet 2 and a backfill; the top plate of the caisson body 1 is provided with a parapet 2 at one end, and the parapet 2 bears the load on the upper part of the wharf surface, and the bottom plate 3 of the caisson body 1 Set on the foundation bed; the interior of the caisson body 1 is evenly provided with a number of longitudinal partitions 5 and transverse partitions 6, the longitudinal partitions 5 and the transverse partitions 6 are crisscrossed, and the longitudinal The backfill is filled between the partitions 6; the back of the caisson body 1 is filled with backfill; the front wall 4 of the caisson body 1 is composed of several concave curved surfaces connected end to end, and the cross section of the concave curved surface is In the shape of an arc.

[0020] The caisson body 1 can adjust the width of the caisson structure according to the berthing requireme...

Embodiment 2

[0023] A caisson gravity type wharf structure, comprising a caisson body 1, a parapet wall 2 and backfill; a parapet wall 2 is provided at one end of the top plate of the caisson body 1, the parapet wall 2 bears the load on the top of the wharf surface, and the bottom plate 3 of the caisson body 1 is arranged on the foundation. The interior of the caisson body 1 is evenly provided with several longitudinal partitions 5 and transverse partitions 6, the longitudinal partitions 5 and the transverse partitions 6 are crisscrossed, and the longitudinal partitions 5 and the transverse partitions 6 Filled with backfill; the back of the caisson body 1 is filled with backfill; the front wall 4 of the caisson body 1 is composed of several concave curved surfaces connected end to end, and the cross section of the concave curved surface is in the shape of a broken line .

[0024] The caisson body 1 can adjust the width of the caisson structure according to the berthing requirements of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com