An automatic ebb drying device for laver culture, a culture device and a tidal range automatic ebb drying method

A technology for laver and tidal range, applied in the field of self-drying devices for laver cultivation, can solve the problems of long operation time, easy rollover or tilt, unstable force on floating rafts, etc., to improve quality and output, and strengthen wind and wave resistance The effect of reducing the cost of breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

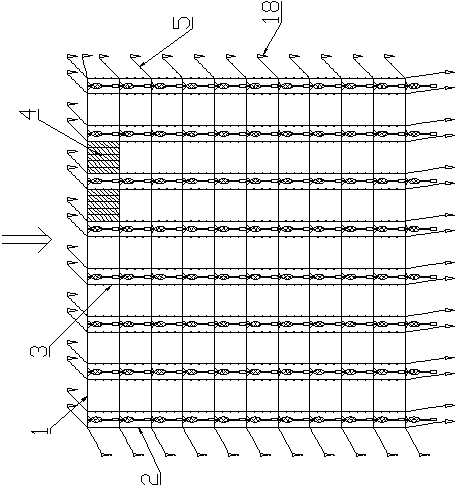

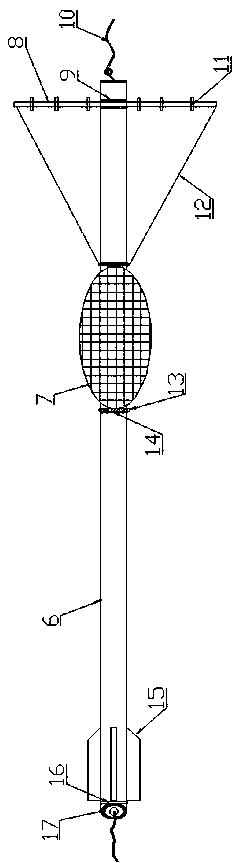

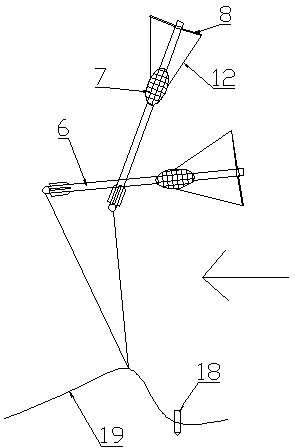

[0022] Embodiment 1, with reference to figure 1 and figure 2 , a self-drying device for laver cultivation, comprising a hollow pick rod 6 and a floating rod 8, one end of the hollow pick rod 6 is vertically fixedly connected to the middle part of the float rod 8, and the other end of the hollow pick rod 6 is uniformly arranged along the circumference of the rod body There are several empennages 15 for stabilizing the hollow poles 6, and the hollow poles 6 between the empennage 15 and the floating poles 8 are covered with large floats 7, and oblique stay ropes 12 are arranged between the large floats 7 and the two ends of the floating poles 8. The hollow pick rod 6 is threaded along the axis of the rod body with a dry root cable 10 that cooperates with the large float 7 to stir up the floating rod 8 .

Embodiment 2

[0023] Embodiment 2, in the self-drying device for laver cultivation described in Embodiment 1: the rod body of the hollow pick rod 6 is composed of a plastic inner tube and a composite material outer tube compounded outside the plastic inner tube. A foam layer is arranged between the composite material outer pipes, and pipe plugs 17 with through holes are arranged at both ends of the hollow pole.

Embodiment 3

[0024] Embodiment 3, in the self-drying device for laver cultivation described in Embodiment 1: the hollow pick rod 6 at the outer end of the tail wing 15 is provided with a first fastening clip for clamping the tail of the hollow pick rod 6 and the tail wing 15 The hoop 16 is provided with the second fastening hoop 9 for clamping the floating rod 8 and the head of the hollow rod 6 on the hollow rod 6 on both sides of the floating rod 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com