Nonwoven fabric

A non-woven fabric, flat technology, applied in the direction of non-woven fabrics, textiles, papermaking, packaging items, etc., can solve the problems of low flatness and insufficient softness of non-woven fabrics, and achieve suitable bulkiness and softness , Good erasability, little irritation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

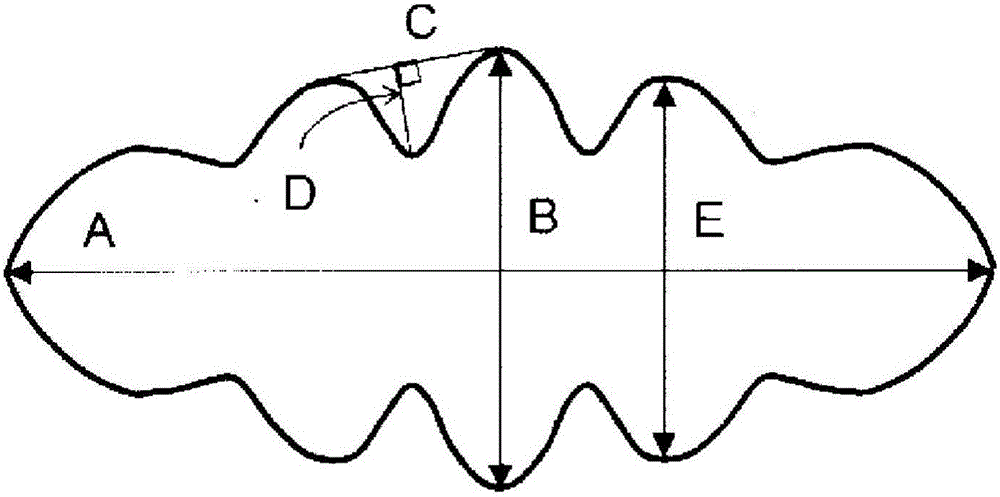

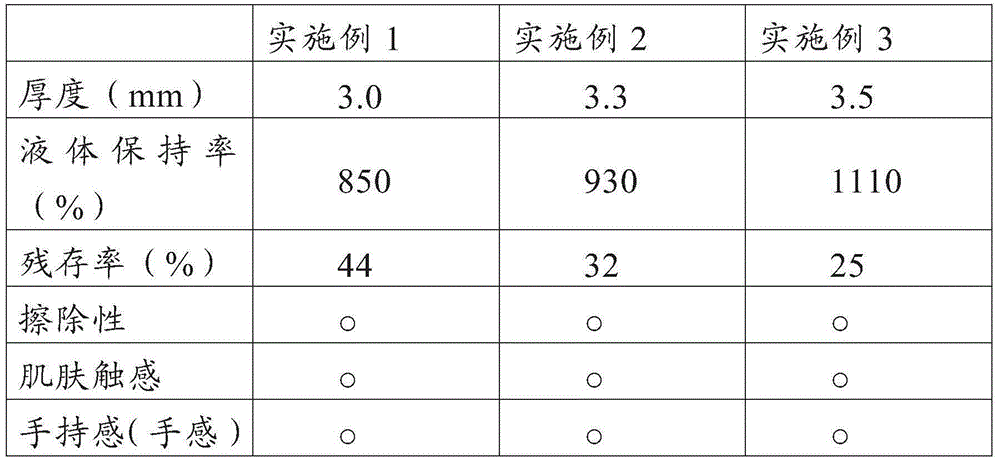

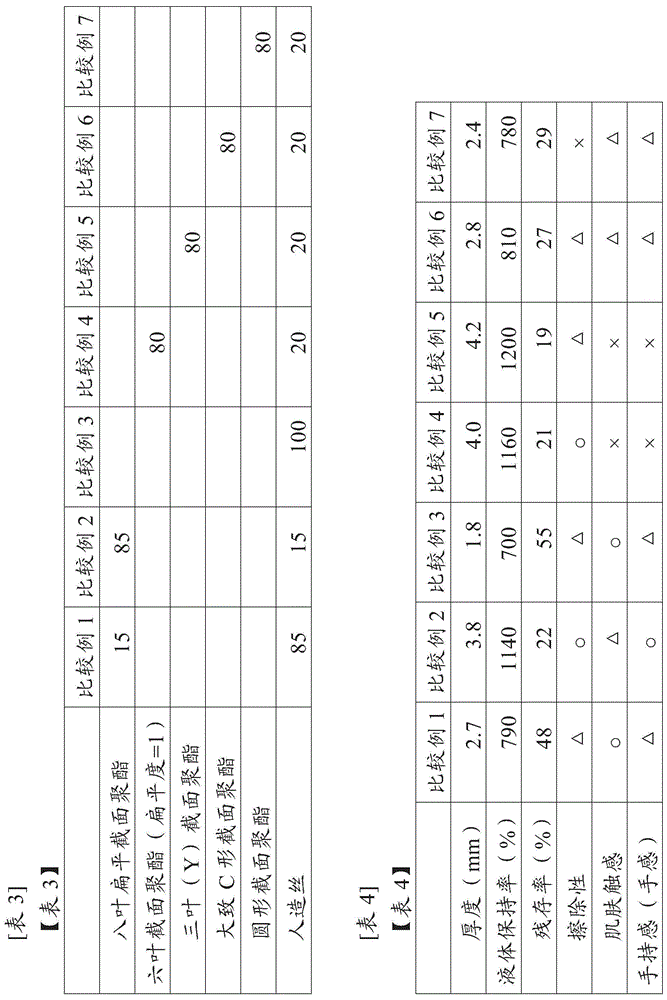

[0083] 20% by mass of a flat multi-lobe cross-section polyester fiber (single fiber fineness: 1.7 dtex, fiber length: 51 mm) with a flatness of 2.1, a degree of irregularity of 2.7, a convex portion ratio of 0.8, and a cross-sectional shape having 8 convex portions After uniformly blending with 80% by mass of rayon fiber (single fiber fineness: 1.7dtex, fiber length: 51mm), the basis weight is 60g / cm by a conventional method. 2 carded fiber web, the hydraulic pressure of water injection (waterjet) is 50kg / cm 2 , speed is 1m / min, nozzle shape: The sheet is produced by double-sided processing under the conditions of 0.6mm pitch, 834 holes, and 500mm effective width, and then dried at a temperature of 120°C to obtain a weight per unit area of 50g / m 2 of non-woven fabrics. Table 1 shows the fiber configuration of the nonwoven fabric, and Table 2 shows the evaluation results.

Embodiment 2

[0085] 50% by mass of a flat multi-lobe cross-section polyester fiber (single fiber fineness 1.7 dtex, fiber length 51 mm) with a flatness of 2.1, a degree of irregularity of 2.7, a protrusion ratio of 0.8, and a cross-sectional shape having 8 protrusions and Rayon fiber (single fiber fineness 1.7dtex, fiber length 51mm) is uniformly mixed with 50% by mass, and the weight per unit area is 60g / cm by a conventional method. 2 Carding machine fiber web, the hydraulic pressure of water injection is 50kg / cm 2 , speed is 1m / min, nozzle shape: The sheet is produced by double-sided processing under the conditions of 0.6mm pitch, 834 holes, and 500mm effective width, and then dried at a temperature of 120°C to obtain a weight per unit area of 50g / m 2 of non-woven fabrics. Table 1 shows the fiber configuration of the nonwoven fabric, and Table 2 shows the evaluation results.

Embodiment 3

[0087] 80% by mass of a flat multi-lobed cross-section polyester fiber (single fiber fineness: 1.7 dtex, fiber length: 51 mm) with a flatness of 2.1, a degree of irregularity of 2.7, a convex portion ratio of 0.8, and a cross-sectional shape having 8 convex portions After uniformly blending with 20% by mass of rayon fiber (single fiber fineness: 1.7dtex, fiber length: 51mm), the basis weight is 60g / cm by a conventional method. 2 carded fiber web, the hydraulic pressure of water injection is 50kg / cm 2 , speed is 1m / min, nozzle shape: After the sheet is produced by double-sided processing under the conditions of 0.6mm pitch, 834 holes, and 500mm effective width, it is dried at a temperature of 120°C to obtain a weight per unit area of 50g / m 2 of non-woven fabrics. Table 1 shows the fiber configuration of the nonwoven fabric, and Table 2 shows the evaluation results.

[0088] [Table 1]

[0089] 【Table 1】

[0090]

Example 1

Example 2

Example 3

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Irregularity | aaaaa | aaaaa |

| Irregularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com