A wire harness tensioning device for a wire arranging machine

A technology of tensioning device and wire arranging machine, which is applied in the direction of electrical components, inductance/transformer/magnet manufacturing, circuits, etc. It can solve the problems of reduced accuracy of arranging wires, difficulty in tensioning and tilting of copper wires, etc., and achieve wire arranging accuracy High and applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

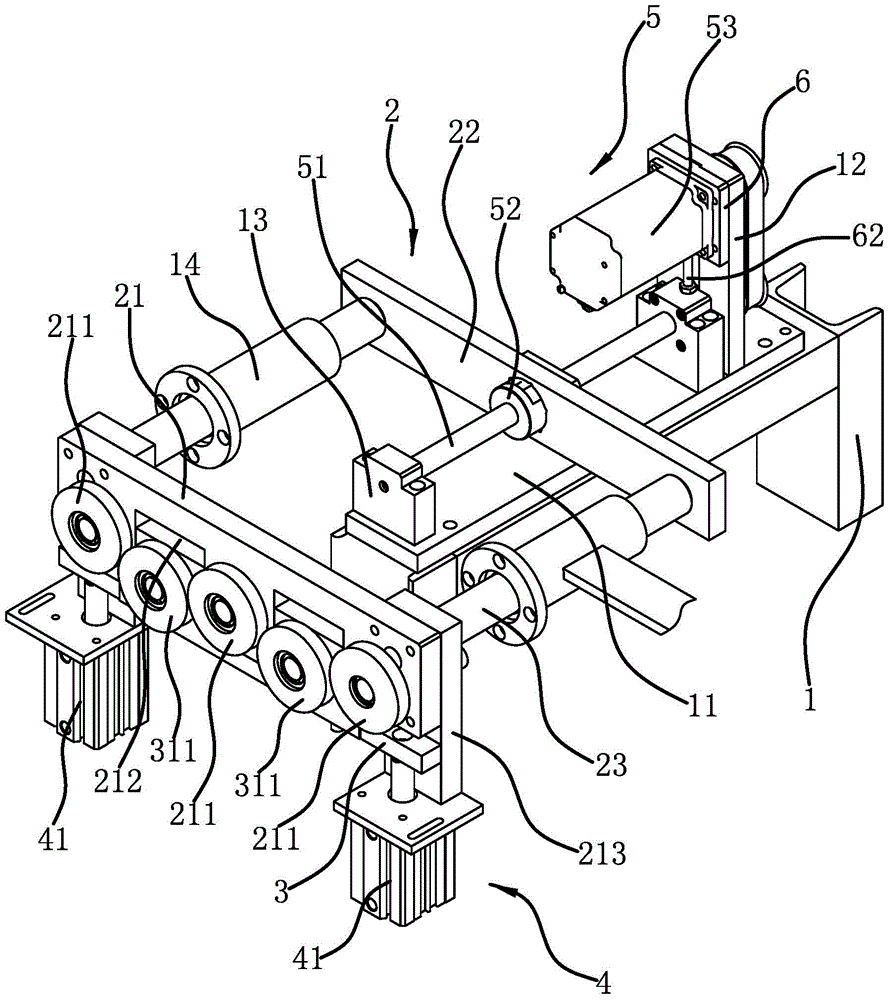

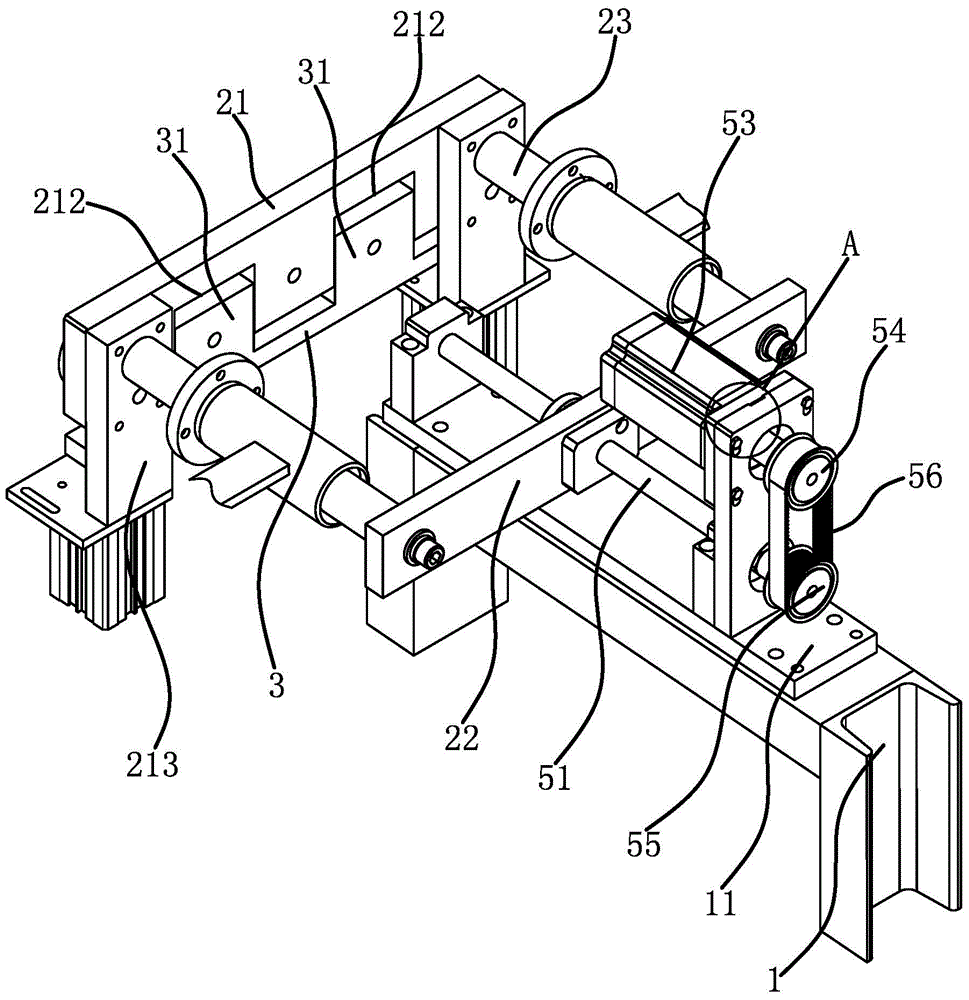

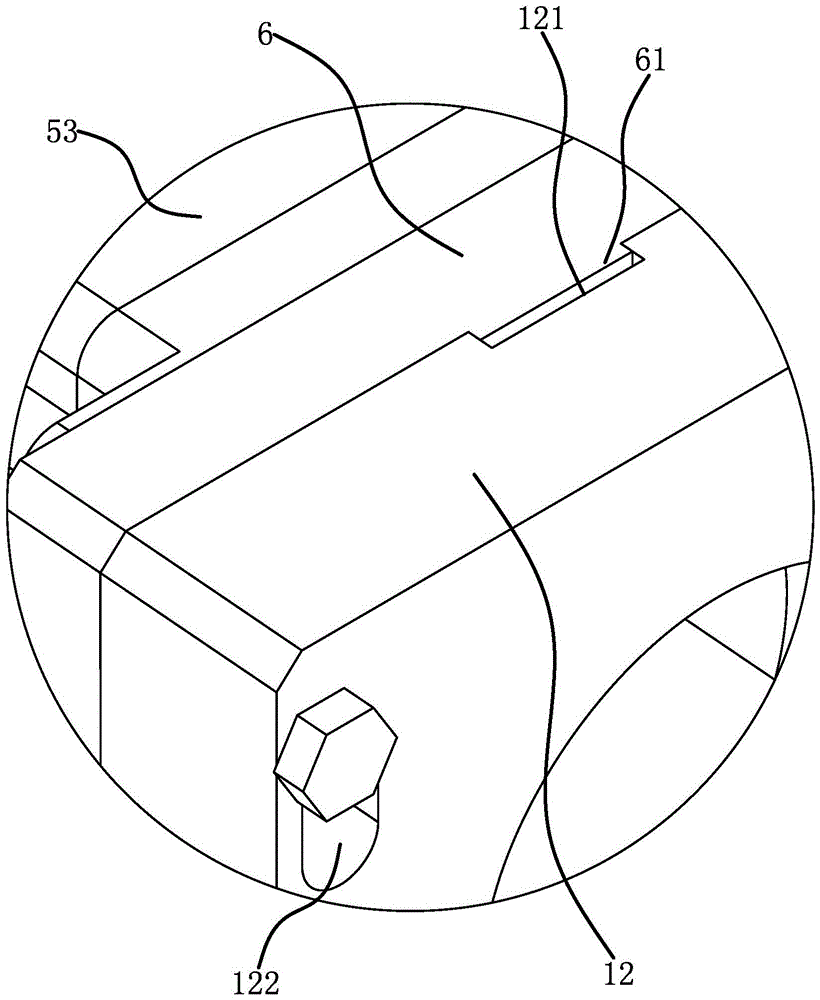

[0025] Such as figure 1As shown, a wire harness tensioning device of a wire arranging machine, the wire arranging machine includes a frame 1, the wire harness tensioning device includes a moving frame 2, the moving frame 2 is slidably connected to the frame 1 in the horizontal direction, and the moving frame 2 includes a fixed Plate 21, the side of this fixed plate 21 is vertically arranged, on the side of fixed plate 21 are hinged with three line pulleys 211, on the fixed plate 21 sliding along the vertical direction is provided with fixed rod 3, on the fixed rod 3 is hinged with two The tensioning wheel 311, the cable arrangement wheel 211 and the tensioning wheel 311 are all arranged in the horizontal direction, the ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com