Step-by-step analysis and prediction method for dynamic performances of rubber material structure

A rubber material and dynamic performance technology, applied in the fields of instruments, computing, electrical digital data processing, etc., can solve the problems of complex superposition process, certain difficulty, and few practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation process of the present invention will be described in detail below with reference to the accompanying drawings.

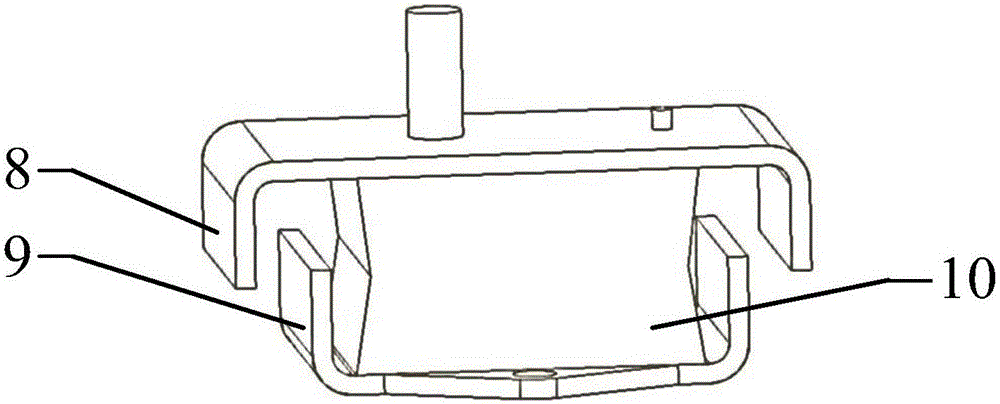

[0055] right as figure 2 The dynamic performance of a rubber isolator shown is analyzed and predicted and compared with experimental test results. The metal upper and lower frames of the rubber vibration isolator are respectively bonded with the rubber material cushion through vulcanization. The present invention includes the following test prediction steps:

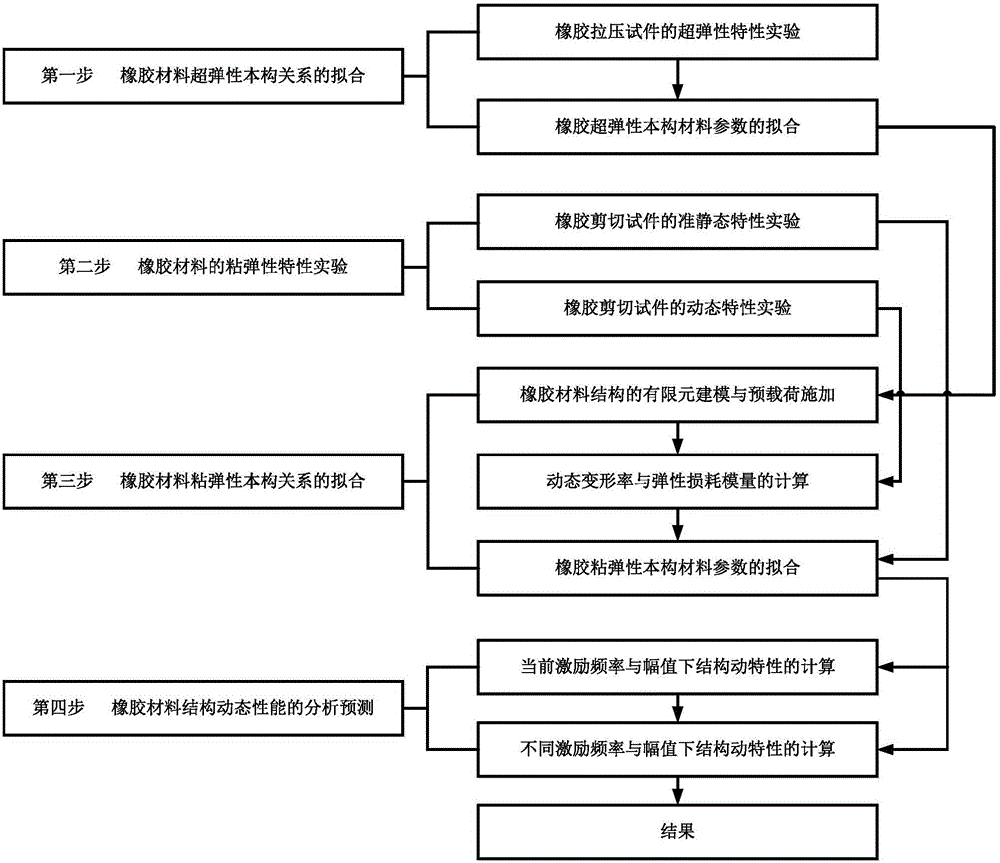

[0056] The first step is the fitting of the hyperelastic constitutive relation of the rubber material

[0057] (1) First, obtain the hyperelastic stress-strain relationship of the rubber material through the quasi-static elastic characteristic test of the rubber tensile and compression specimen: using the same batch of rubber material as the target rubber material structure, prepare such as image 3 Cylindrical test block shown; as Figure 4 Dumbbell-shaped test piece s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com