A temperature-measuring microwave oven and its working control method

A technology for microwave ovens and control devices, which is applied to household stoves/stoves, household heating, lighting and heating equipment, etc. It can solve problems such as microwave leakage and reliability impact, and achieve the effect of preventing excessive operating temperature and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

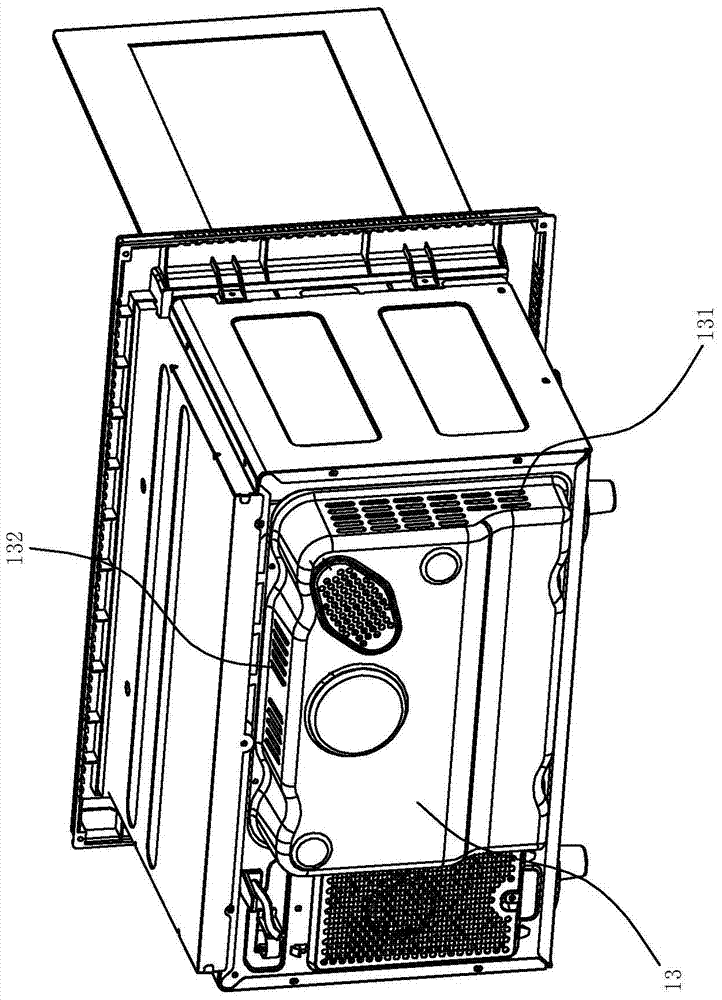

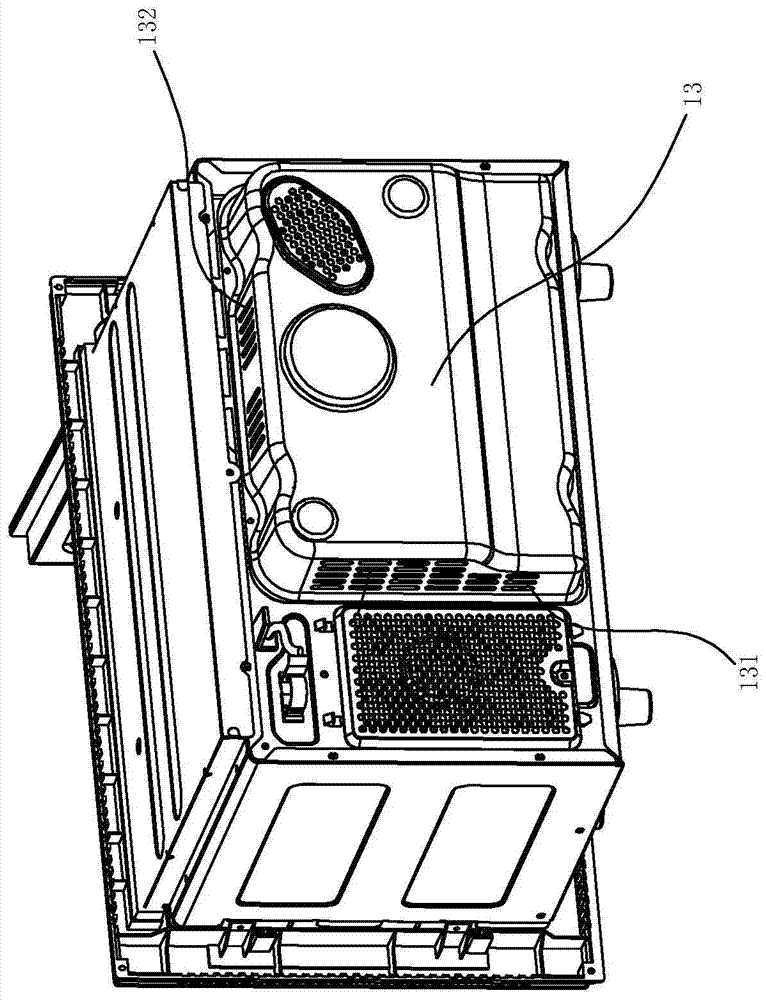

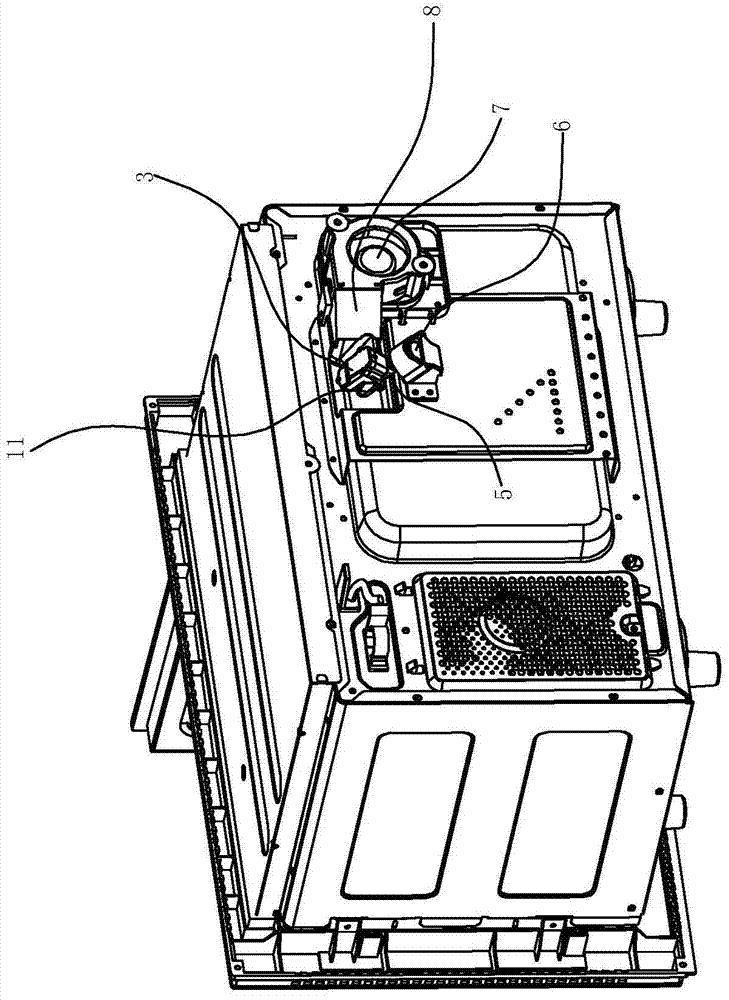

[0025] Such as Figure 1~6 The shown temperature-measuring microwave oven includes a microwave heating cavity 1 for placing the object to be heated, and a flat plate 2 for placing the object to be heated in the microwave heating cavity for generating microwaves to heat the heated object in the microwave heating cavity. A magnetron heating tube (not shown in the figure) for heating the object, and a non-contact temperature detection device 3 for detecting the temperature of the object to be heated. The upper rear part of the microwave heating chamber 1 is provided with an opening near the upper part. 11. The shape of the opening is U-shaped, and the periphery of the opening has a flange 12 facing out of the microwave heating chamber. The height of the flange 12 is 2 mm to 5 mm. The shape of the opening can also be replaced by an ellipse, so Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com