Steam generation tank used for power station

A power station and generation tank technology, applied in the field of solar power generation, can solve the problems of reducing the power generation efficiency of the heat engine and the transmission loss of heat energy, etc., and achieve the effect of improving the efficiency of efflux, increasing the efficiency, and increasing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

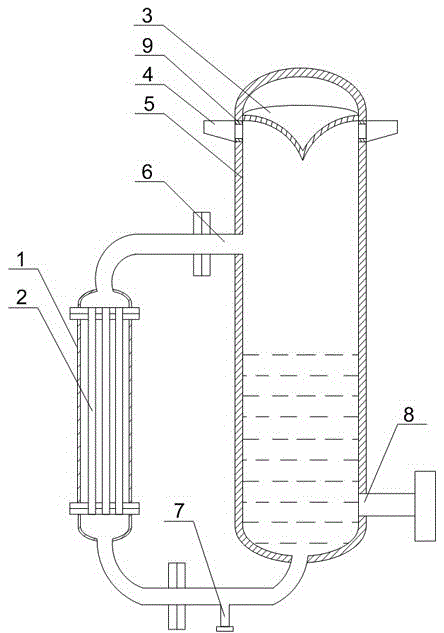

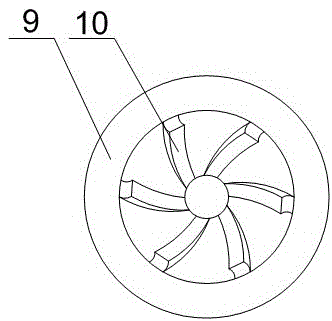

[0022] Such as figure 1 and figure 2 As shown, the present embodiment includes a tank body 5 and a solar external heat pipe 1, the bottom of the tank body 5 communicates with the bottom of the solar external heat pipe 1 through a conduit, and the middle part of the tank body 5 communicates with the top of the solar external heat pipe 1 through a conduit. The side wall of the tank body 5 is provided with a liquid inlet pipe 8, and two mutually symmetrical air outlet pipes 4 are arranged on the top side wall of the tank body 5, and the inner walls of the two air outlet pipes 4 are rotated to be provided with Nozzle 9, and a plurality of spiral protrusions 10 are installed on the inner wall of the nozzle 9, a deflector 3 is fixed on the top of the tank body 5, the middle part of the deflector 3 protrudes downward to form an inverted cone, and the The outer conical surface of the inverted cone is bent inward along its center line, and the axis of the air outlet pipe 4 is facing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com