Method for green extraction of seabed unstratlfied rock natural gas hydrate

A mining method and technology for natural gas, which are applied in the fields of production of fluids, earth-moving drilling, wellbore/well components, etc., can solve the problems of large mechanical energy consumption, high production cost, unfavorable large-scale commercial production of natural gas hydrate, etc. Cost, high collection efficiency, exquisite design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

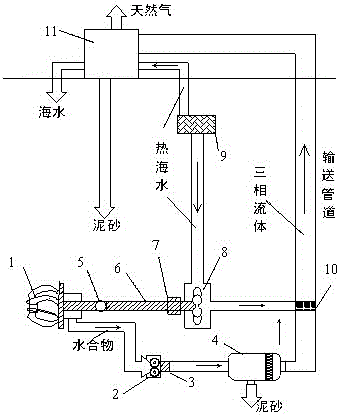

[0025] Embodiment one: figure 1 It shows an embodiment of a seabed non-diagenetic natural gas hydrate collection device of the present invention. A seabed non-diagenetic natural gas hydrate collection device includes a hydraulic turbine 8, which is connected to a seawater introduction pipeline. The output shaft of the water conservancy turbine 8 is connected with the mining head 1, a particle collection pipeline is arranged near the mining head 1, a separator 4 is arranged on the particle collection pipeline, and a sediment discharge port is also provided on the separator 4 , the outlet pipe of the water conservancy turbine 8 is collected with the particle collection pipe, and is connected with the outlet pipe, and a blender 10 is arranged at the collection place, and the outlet pipe is connected with the integrated treatment platform 11, and the integrated treatment platform 11 is also provided with a seawater inlet pipe, a natural gas discharge port, an impurity discharge po...

Embodiment 2

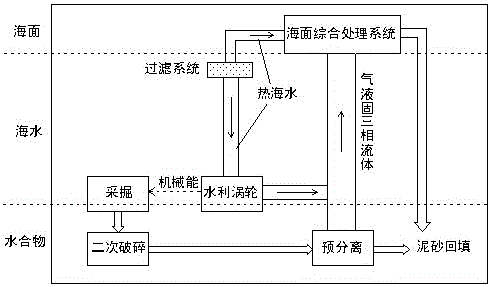

[0027] Figure 1-2 It shows an embodiment of a green mining method of seabed non-diagenetic natural gas hydrate in the present invention, the mining method is realized by a special mining device for green mining of seabed non-diagenetic natural gas hydrate, and the mining device includes: mining head 1 , a separator 4, a blender 10, a delivery pipeline and an integrated processing platform 11, the mining method comprises the following steps:

[0028] Step 1. Pretreatment of natural gas hydrate: without changing the temperature and pressure of the seabed, the natural gas hydrate solid on the seabed is crushed by mining head 1;

[0029] Step 2. Pre-collection of natural gas hydrate: send the crushed natural gas hydrate solid into the collection pipeline, and enter the separator 4 for separation, and temporarily store the suitable natural gas hydrate;

[0030] Step 3. Collection of natural gas hydrate: By changing part or all of the broken natural gas hydrate into a gaseous stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com