High molecular material surface modification discharge reactor

A technology of polymer material and surface modification, applied in the field of polymer material surface modification discharge reactor, can solve problems such as sparks, uneven modification treatment, etc., and achieve the effect of uniform modification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

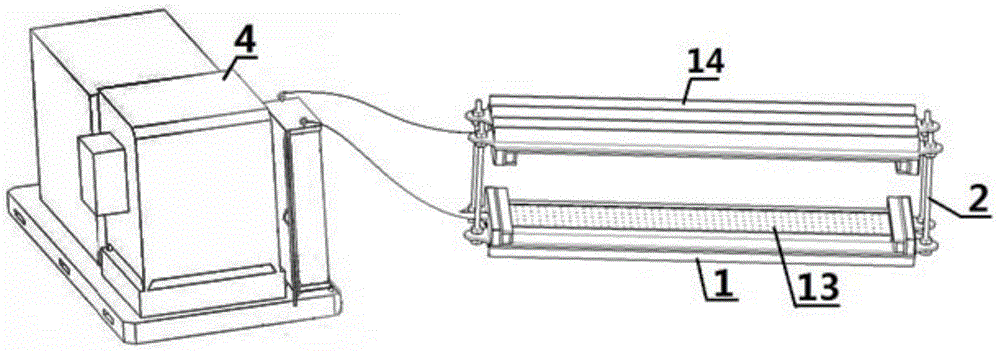

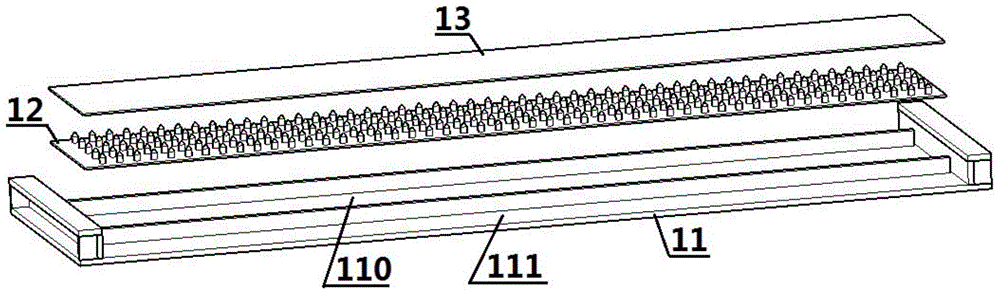

[0027] The structure of the polymer material surface modification discharge reactor of the present embodiment is as follows:

[0028] Please combine Figure 1-2 It should be understood that the discharge reactor for surface modification of polymer materials in this embodiment is used for modifying the surface of polymer materials, and it includes four adjustment screws 2 and two plate-shaped discharge components 1. These adjustment The screw 2 is penetrated and fixed on the four ends of the discharge parts 1, each discharge part 1 includes an insulating shell 11 with a groove 110, a PCB discharge plate 12 uniformly distributed with discharge needles and a catalyst carrier 13. The PCB discharge plates 12 are set in the grooves 110, the catalyst carriers 13 are embedded in the mouths of the grooves 110 and potted with flame-retardant epoxy resin, and the catalyst carriers 13 are parallel to And oppositely arranged, the discharge needles are used to excite the catalyst carriers ...

Embodiment 2

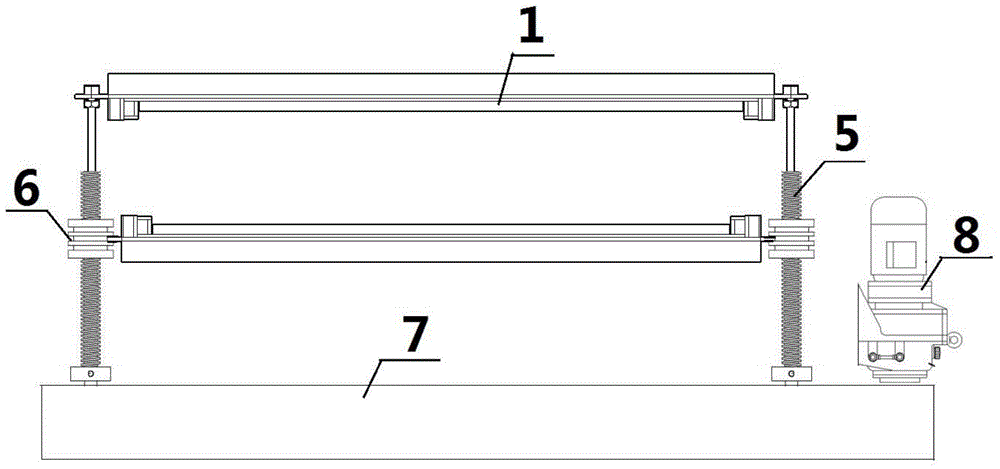

[0040] The structure of the polymer material surface modification discharge reactor of the present embodiment is as follows:

[0041] Please combine image 3 It should be understood that the discharge reactor for surface modification of polymer materials in this embodiment has many similarities with the discharge reactor for surface modification of polymer materials in Example 1, and these similarities will not be repeated here.

[0042] Please combine image 3It should be understood that the polymer material surface modification discharge reactor of the present embodiment also includes a motor 8 and a synchronous driving device 7, and the adjusting screws 5 each have a pivot portion and a screw rod portion, and the discharge components One discharge part in 1 is pivotally connected to these pivot parts, the other discharge part in these discharge parts 1 is pivotally connected to these screw rod parts, and the motor 8 is used to drive these adjustments through the synchronou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com