A method for installing anchor bolts in steel structures

An anchor bolt and installation method technology, applied in the field of construction and installation, can solve the problems of failing to meet specification requirements, increasing workload, wasting time and human resources, and achieving the effects of improving construction efficiency, saving construction time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

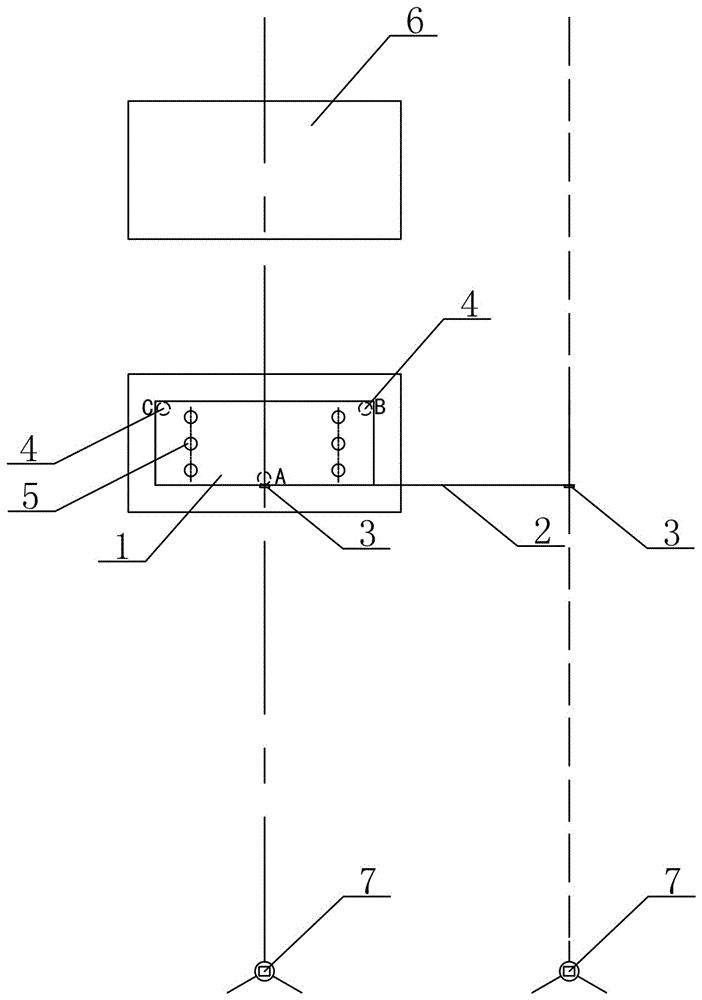

[0024] The present invention adopts the total station and theodolite to uniformly locate the installation molds arranged on the foundation bolts of each platform on the axis, so that the pre-embedded bolts can be positioned accurately and quickly, and the specific positioning and installation are carried out according to the following steps:

[0025] (1) Production of installation mold

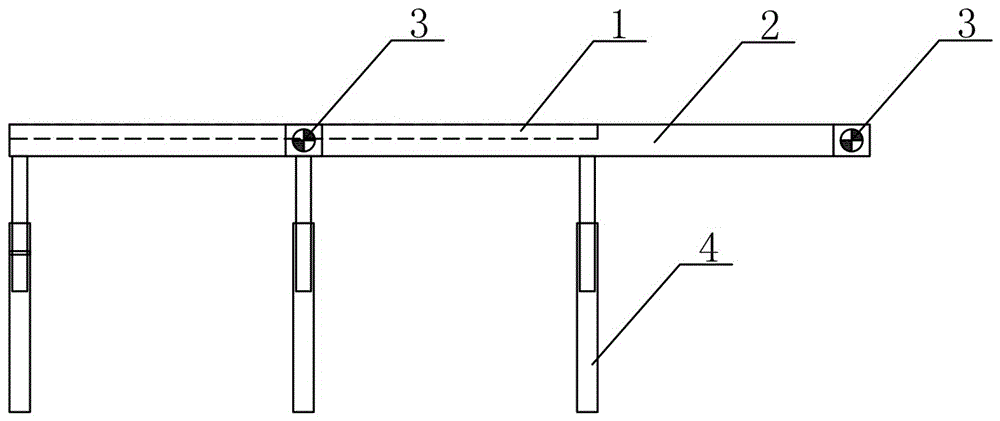

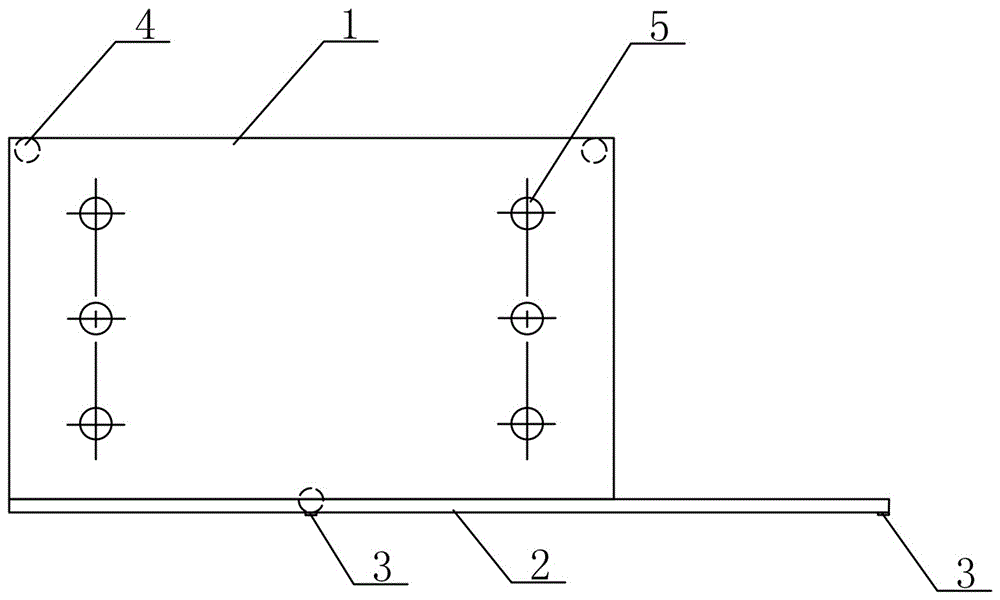

[0026] See attached figure 1 ~ attached figure 2 The installation mold is composed of a positioning steel plate 1, an adjustable steel pipe 4 and a reflector 3. The positioning steel plate 1 is provided with a positioning hole 5. The positioning steel plate 1 is made of a 20mm thick steel plate. The positioning hole 5 is made of a mechanical hole, and the aperture is larger than the embedded The diameter of the bolt is 2mm, and the axis of the aperture is marked on the positioning steel plate 1 by the cutting groove of the saw blade; the adjustable steel pipe 4 is arranged in three places A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com