Ultrathin stone polyurethane and ceramsite composite plates and machining method thereof

A processing method, polyurethane technology, applied in the field of building materials, can solve the problems of insufficient stone support strength, easy deformation, long production time, etc., and achieve the effect of simple and convenient processing method, strong toughness, pressure resistance, and strong adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

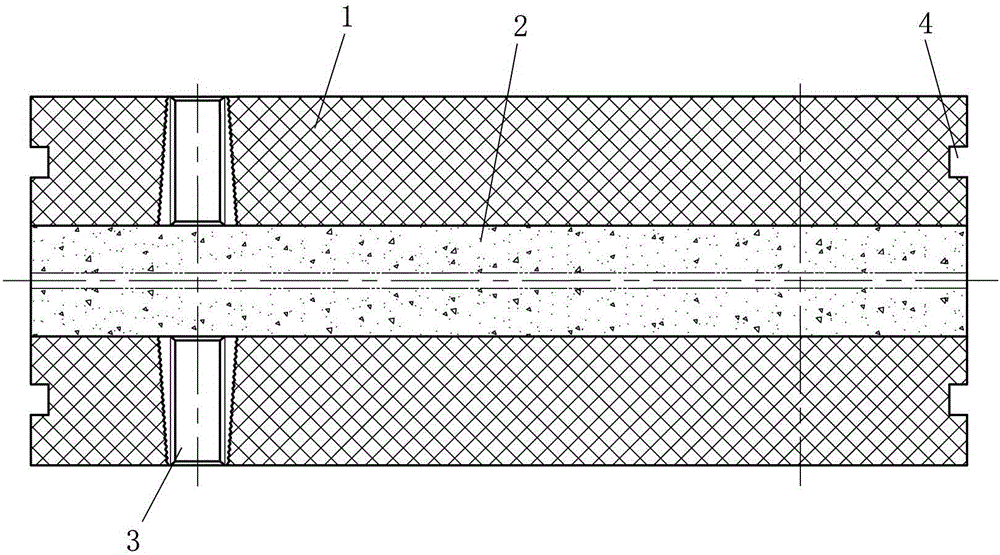

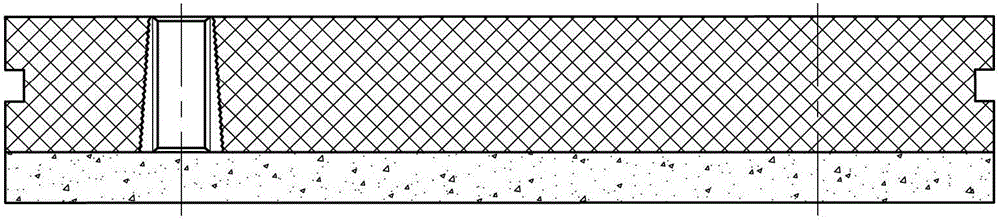

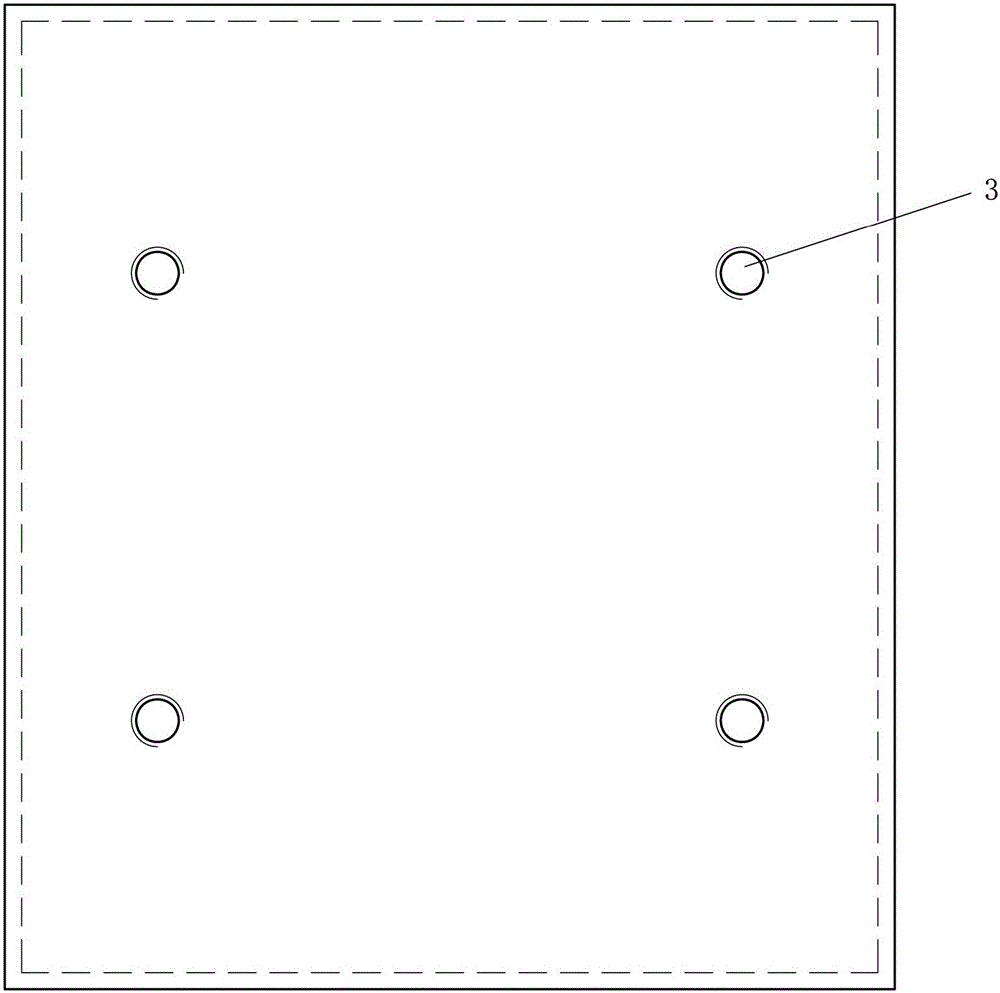

[0030] refer to Figure 1 to Figure 5 , figure 1 It shows an example diagram of cutting the natural stone with all-water polyurethane ceramsite boards bonded on both sides into two ultra-thin stone all-water polyurethane ceramsite composite boards in the present invention. It uses 800mmх800mm natural stone with a thickness of 16mm; uses 1:2 weight percentage of full-water polyurethane and ceramsite, and mixes them evenly to make full-water polyurethane ceramsite board 1, and the thickness of the board is 30mm. During the preparation, four pieces of conical nuts were selected to be pre-embedded in the all-water polyurethane ceramsite board 1 as the connecting hole 3 for hanging on the wall; inorganic stone bonding glue was selected to be bonded on both sides of the natural stone 2 Put the full water polyurethane ceramsite board 1. When bonding, bond the big head side of the conical nut to the stone side to strengthen the connection strength of the nut. Then, the natural stone...

Embodiment 2

[0032] refer to Figure 1 to Figure 5 , Using the same method as in the above-mentioned embodiment, in this embodiment, the natural stone with the all-water polyurethane ceramsite board bonded on both sides is cut into two or more ultra-thin stone all-water polyurethane ceramsite composite boards. Use 600mmх600mm natural stone with a thickness of about 23mm. The thickness of the all-water polyurethane ceramsite board 1 is 25mm. In the installation hole 3, there are pre-embedded expansion bolts 5 that can be connected; Bond the full water polyurethane ceramsite board 1; use a 4mm thick saw blade to cut out an ultra-thin stone full water polyurethane ceramsite composite board with a stone thickness of 5mm, and then glue it on the other side of the remaining 14mm stone 2 The full water polyurethane ceramsite board 1 is then cut from the middle of the stone 2, and three pieces of ultra-thin stone full water polyurethane ceramsite composite boards with a thickness of about 5mm are ...

Embodiment 3

[0035] refer to Figure 1 to Figure 5 , is identical with the processing method of above-mentioned embodiment 1. Use brown natural marble with a thickness of 600mmх300mm and a thickness of 12mm; use 1:1 weight percentage of full-water polyurethane and ceramsite to mix evenly, and make a plate with a thickness of 20mm full-water polyurethane ceramsite board 1. Select 2 pieces of conical nuts to pre-embed in the connection hole 3 of the full water polyurethane ceramsite board 1; use full water polyurethane to bond the full water polyurethane ceramsite board 1 on both sides of the natural marble, and bond the two sides with the full water polyurethane The natural marble of ceramsite board 1 is cut along the center line into two ultra-thin stone full-water polyurethane ceramsite composite boards with a stone thickness of 4mm. Groove 4 is processed around the cut all-water polyurethane ceramsite board, the marble surface is ground and polished, and finally an ultra-thin stone full...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com