Efficient gas type stepping furnace

A gas-fired, walking furnace technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of temperature uniformity inside the furnace body, large temperature difference inside the furnace body, affecting the heat treatment effect, etc., to improve the heat treatment effect, Uniform flow, good for heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

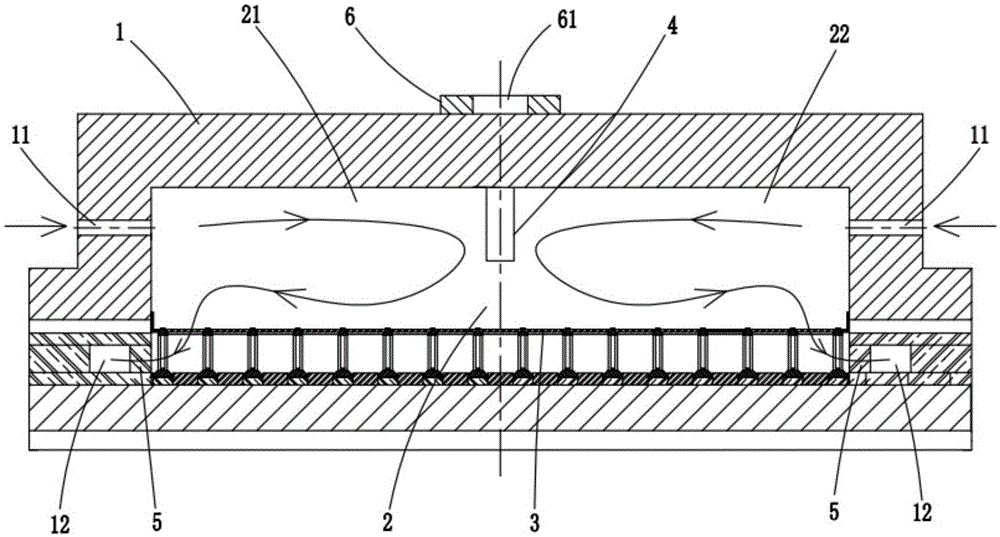

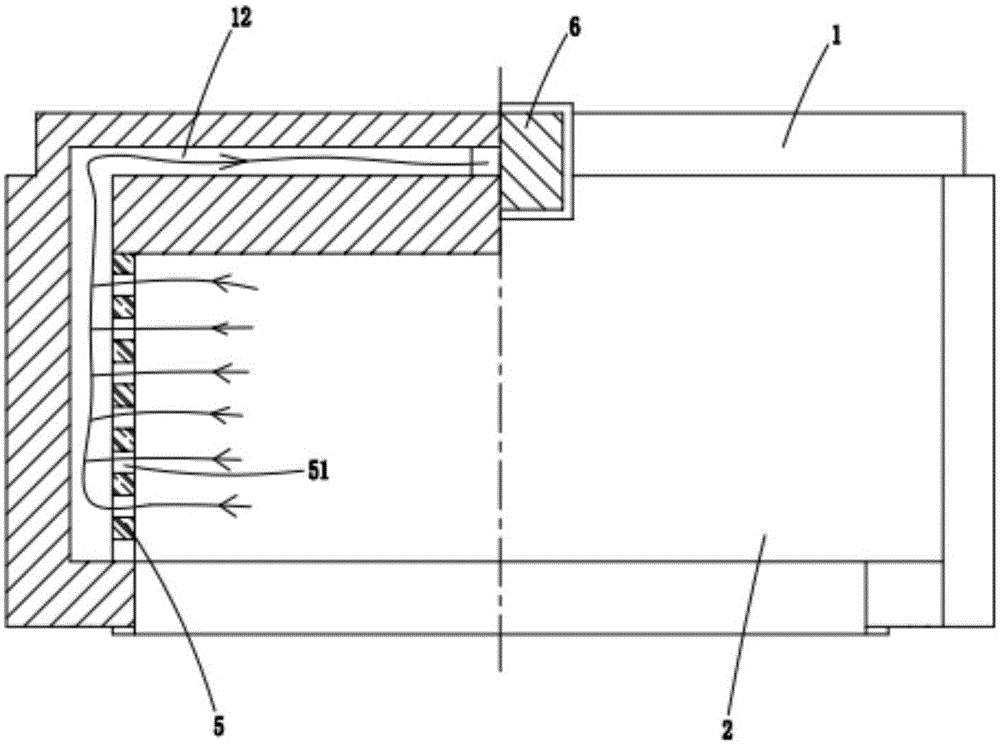

[0023] Such as figure 1 As shown, the present invention provides a high-efficiency gas-fired walking furnace, including a furnace shell 1 and a furnace 2. The furnace shell 1 is a rectangular box-shaped body, which is made of welded steel and steel plates, and has the rigidity required for the normal operation of the furnace body. and strength, the feed end of the furnace shell 1 is provided with a material inlet, and a material outlet is provided at the discharge end. According to the product heat treatment process requirements, the size of the furnace 2 is designed to be 4500mm×2650mm×600mm, and the furnace 2 is provided with a place for placing workpieces. The storage rack 3 has high-temperature flue gas inlets 11 connected to the burner nozzles on the upper left and right sides of the furnace shell 1 according to the heating volume. The high-temperature flue gas inlets 11 are all connected to the furnace 2 to improve the heating efficiency and benefit Heat treatment procee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com