Method for producing green plum impregnated wine

A production method and green plum wine technology, applied in the field of food manufacturing, can solve the problems of difficult control, high requirements for fermentation equipment and fermentation enzymes, and achieve the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

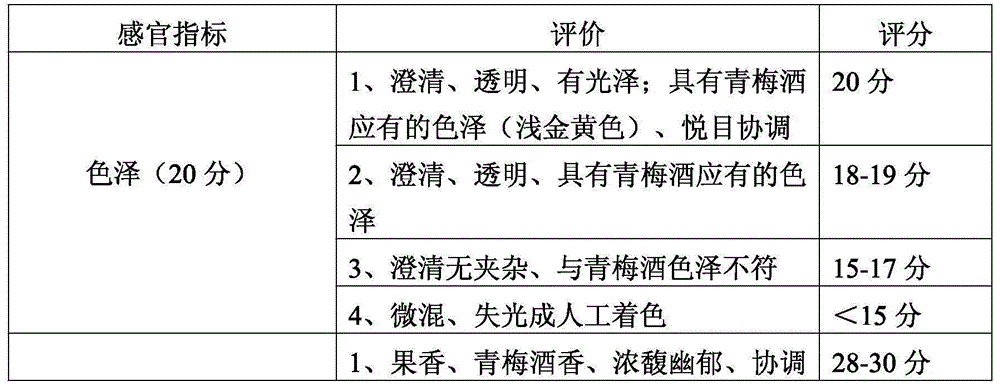

Examples

Embodiment 1

[0029] (1) select the non-astringent green plum 1kg that fruit expands but does not turn yellow, and what the present invention adopted is Suzhou Xishan fruit plum. Store at 20°C for 24 hours, carefully remove the stalks with a toothpick (do not break the fruit), clean (do not rub), and dry naturally to ensure that the greengage is not damaged;

[0030] (2) The glass container is sterilized and dried naturally; alternately add green plums and rock sugar to a clean and sterile glass container, wherein the quality of the sugar is 300g, carefully shake the glass container from time to time during the adding process to ensure that the green plums and sugar Fully mix; add 45° brewed white wine (Wuliangye Group Co., Ltd.) to the plum sugar mixture, the weight is 1.2 times that of green plum; soak at 22°C for 8 months to obtain green plum wine puree;

[0031] (3) Green plum wine aging: the green plum wine puree obtained in step (2) is filtered through a 10 μm filter membrane, and sea...

Embodiment 2

[0034] (1) select the non-astringent green plum 1kg that fruit expands but does not turn yellow, and what the present invention adopted is Suzhou Xishan fruit plum. Store at 22°C for 20 hours, carefully remove the stalks with a toothpick (do not break the fruit), clean (do not rub), and dry naturally to ensure that the greengage is not damaged;

[0035] (2) The glass container is sterilized and dried naturally; add green plums and rock sugar alternately into a clean and sterile glass container, wherein the quality of the sugar is 200g, and carefully shake the glass container from time to time during the adding process to ensure that the green plums and sugar Mix well; add 55 ° brewed liquor (Wuliangye Group Co., Ltd.) to the plum sugar mixture, the weight is 1 times that of green plum; soak at 24 °C for 6 months to obtain green plum wine puree;

[0036] (3) Green plum wine aging: the green plum wine puree obtained in step (2) is filtered through a 10 μm filter membrane, and se...

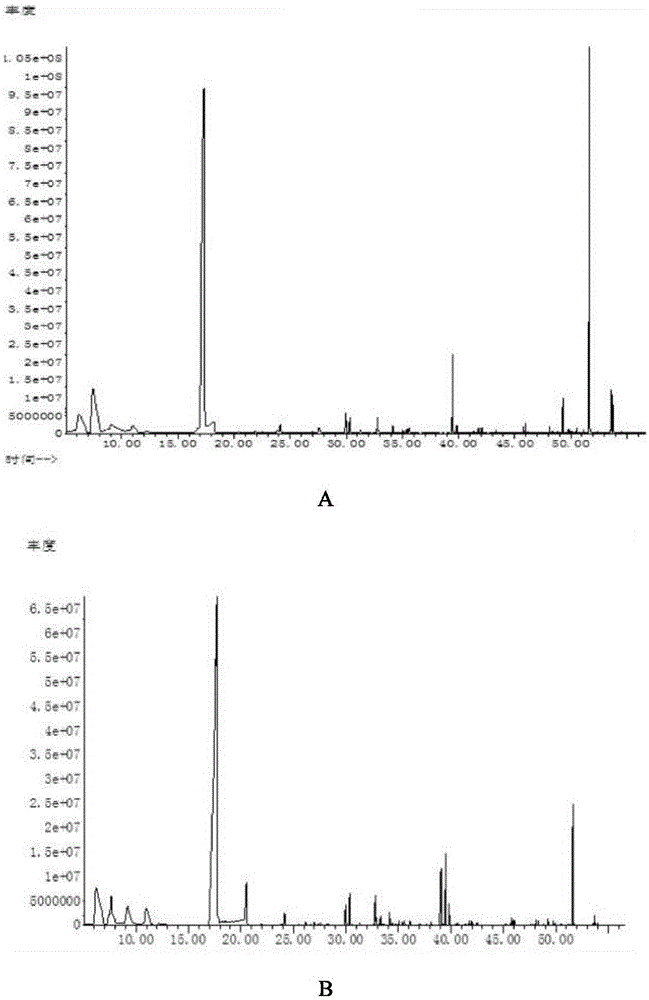

Embodiment 3

[0039] 3.1 Process according to the materials and methods of Example 2, but perform high-temperature transient heat treatment at 120°C-126°C for 8-9s after membrane filtration in step (3) and then seal and seal.

[0040] 3.2 Controlled test:

[0041] Control 1: Treated according to the materials and methods of Example 2, but the fruit plums were not stored at 20°C for 24 hours, nor were they subjected to membrane filtration and airtight storage in step (3).

[0042] Control 2: Treated according to the materials and methods of Example 2, but the fruit plum wine was directly packaged and sealed without ultrasonication or heat treatment at 75°C.

[0043] Control 3: Treated according to the materials and methods of Example 2, but the fruit plum wine was not stored at 20°C for 24 hours, nor was it heat-treated at 75°C, and was directly packaged and sealed.

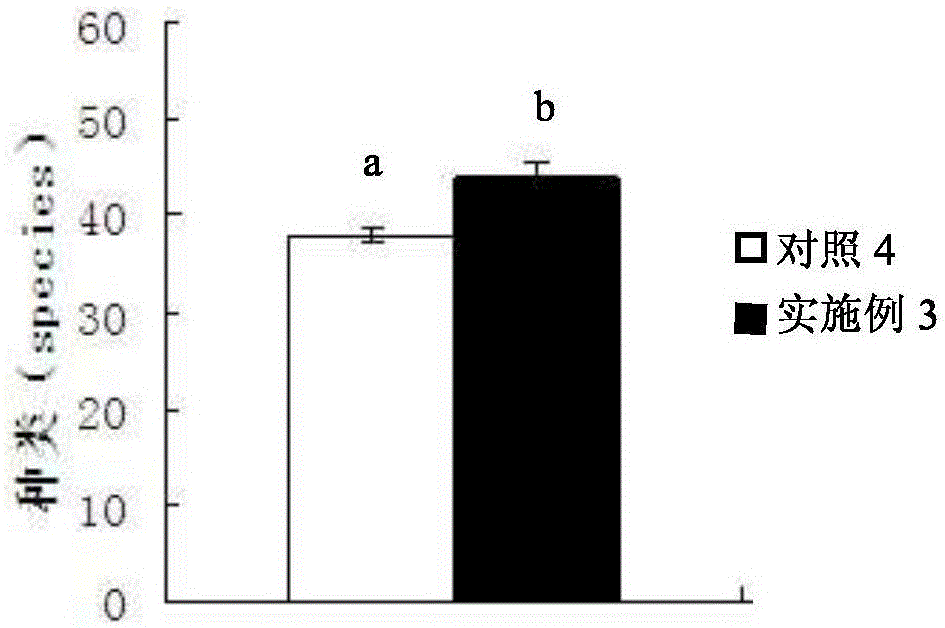

[0044] Control 4: According to the materials of Example 2, according to the traditional method: clean greengage, dry, mix pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com