Potassium fertilizer controlled release coating agent

A coating agent and potash fertilizer technology, applied in coating agent, new fertilizer preparation, granular potash fertilizer coating, potash fertilizer controlled release coating agent, making it the field of controlled release potash fertilizer, which can solve the problem of unsynchronized demand, waste and release Nutrient excess and other problems, to achieve the effect of maintaining integrity, improving utilization, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

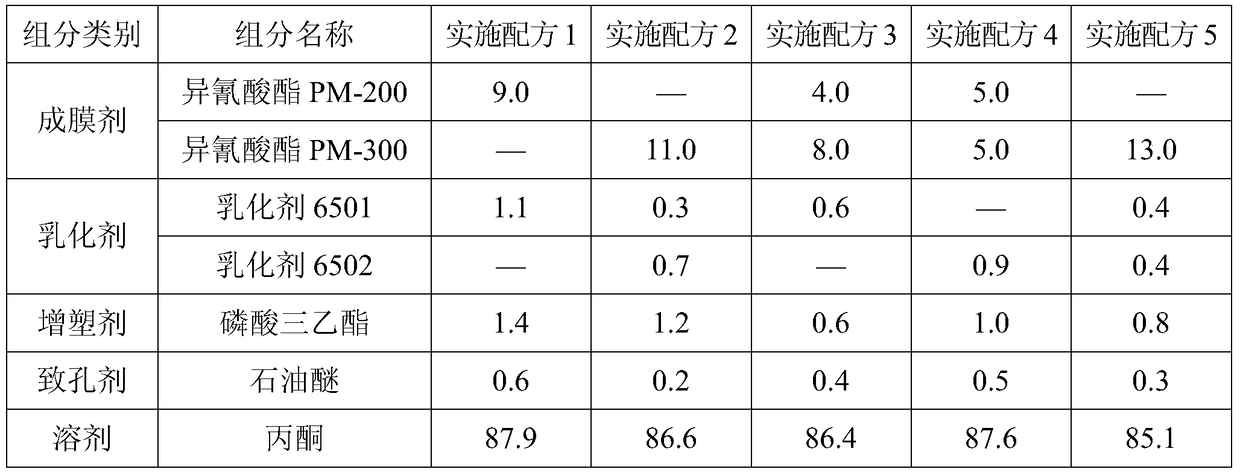

[0035] Taking the production of 100Kg potassium fertilizer controlled-release coating agent as an example, five non-limiting implementation formulas are shown in Table 1.

[0036] Table 1 non-limiting implementation formula of the present invention (unit: Kg)

[0037]

[0038] According to the formula requirements, put the film-forming agent into the dissolution tank with a stirring device, pump the solvent into the solvent with a metering pump, and stir at room temperature of 15°C to 30°C to dissolve the film-forming agent; then add the emulsifier, plasticizer, Pump the porogen into the dissolution kettle, stir and mix evenly to obtain a mixed solution; pump the mixed solution into the emulsification kettle, emulsify and homogenize it at room temperature of 15°C to 30°C for 20 minutes, and fill it with a liquid quantitative filling machine. The potassium fertilizer controlled-release coating agent is obtained.

Embodiment 2

[0040] According to the formula requirements, film former: isocyanate PM-20015%; emulsifier: emulsifier 65010.9%; plasticizer: triethyl phosphate 1.2%, porogen: petroleum ether 0.5%, solvent: acetone to 82.4%.

[0041] According to the requirements of the above formula, put the film-forming agent into the dissolution tank with a stirring device, pump the solvent with a metering pump, stir at room temperature of 15°C to 30°C to dissolve the film-forming agent; then put the emulsifier and plasticizer in sequence 1. Pump the porogen into the dissolution kettle, stir and mix evenly to obtain a mixed solution; pump the mixed solution into the emulsification kettle, emulsify and homogenize it at a room temperature of 15°C to 30°C for 20 minutes, and fill it with a liquid quantitative filling machine , to obtain the controlled-release coating agent of potassium fertilizer. Tests show that the coated potash fertilizer made from the coated ordinary granular potassium fertilizer of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com