Spinning and winding machine guided by guide rod

A guide rod and winding machine technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of user inconvenience, accidents, low winding efficiency, etc., and achieve simple overall structure and easy operation Safe and reliable, easy to disassemble and transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

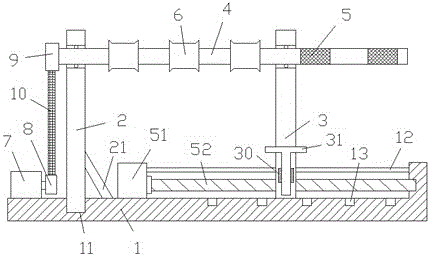

[0013] refer to figure 1 As shown, a textile winding machine guided by a guide rod of the present invention includes a base 1, a fixing hole 11 arranged on the left side of the base 1, and an insertion hole 13 arranged on the right side of the base 1, and inside the fixing hole 11 The left frame 2 is inserted, the base 1 on the left side of the left frame 2 is provided with a rotating motor 7, the driving shaft of the rotating motor 7 is provided with a driving wheel 8, and the right side of the base 1 is also slidably provided with a The right frame 3, the tops of the left frame 2 and the right frame 3 are pierced with a bobbin rod 4, and the bobbin rod 4 is rotatably connected with the left frame 2, and the bobbin rod 4 is connected with the The right frame 3 is rotatably and slidably connected, the bobbin rod 4 is provided with a bobbin anti-skid pad 5, and the bobbin non-slip pad 5 is provided with a bobbin 6, and the bobbin rod 4 The left side of the left side is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com