Tapered positioning device for roll paper of paper interleaving machine

A technology of positioning device and backing paper machine, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of insufficient tightening force of the inflatable shaft, lower production efficiency, and breakage of the backing paper, etc., to achieve guaranteed Product quality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

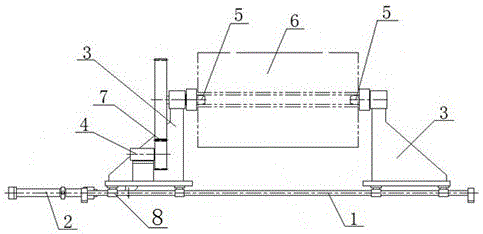

[0013] Such as figure 1 As shown, a cone-shaped positioning device for paper liner rolls includes a guide rail 1, a hydraulic cylinder 2 is installed at one end of the guide rail 1, and two relative moving brackets 3 are installed on the guide rail 1, so that The mobile support 3 is a triangular support. A slide block 8 is installed at the bottom of the mobile support 3 , and the slide block 8 is on a guide rail to control the sliding of the mobile support 3 . There are 4 slide blocks 8 in total, and 2 slide blocks 8 are installed on each mobile support 3 . Tapered positioning shafts 5 are respectively installed on the tops of the two relative mobile supports 3, and a paper roll 6 is fitted between the two tapered positioning shafts 5, and a drive motor 4 is also installed on the mobile supports 3. And the transmission gear 7, the paper roll 6 on the tapered positioning shaft 5 is driven by the drive motor 4 and the transmission gear 7 to rotate.

[0014] The invention chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com