A Negative Gap Rolling Method for Ultra-thin Metal Strips with Online Adjustable Differential Speed Ratio

A different speed ratio, negative roll gap technology, applied in metal rolling, rolling force/roll gap control, roll speed control, etc. Vibration and other problems, to achieve the effect of expanding the scope, increasing the amount of thinning, and improving the rolling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

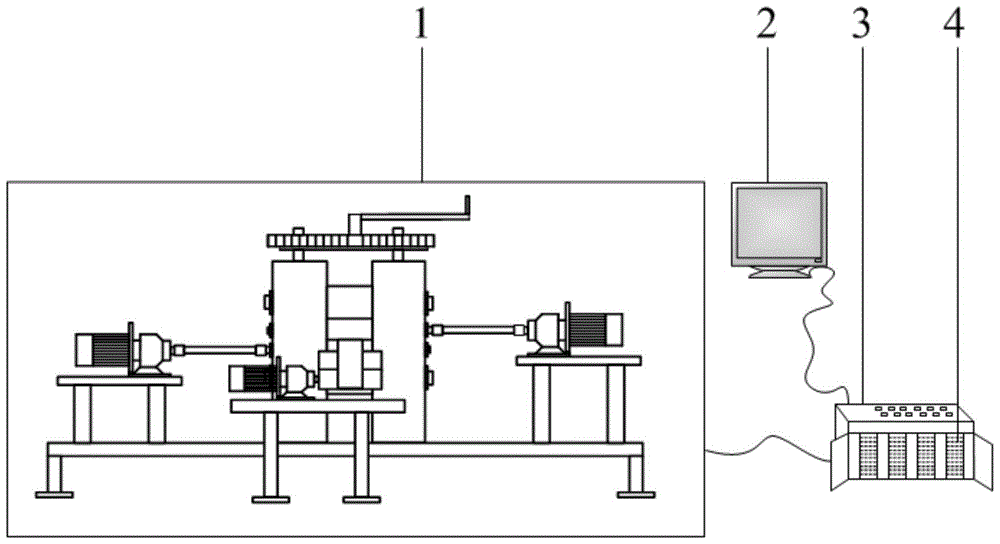

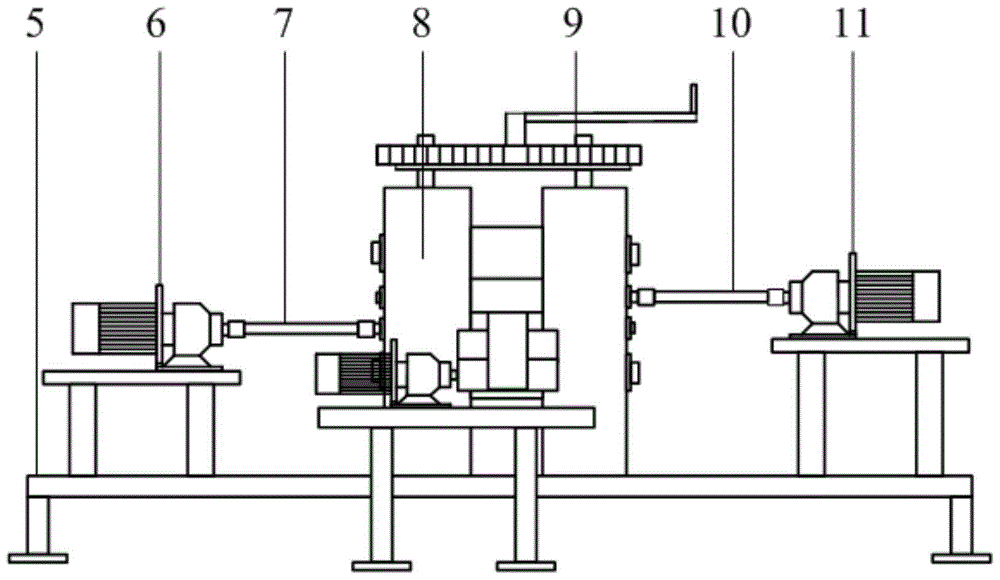

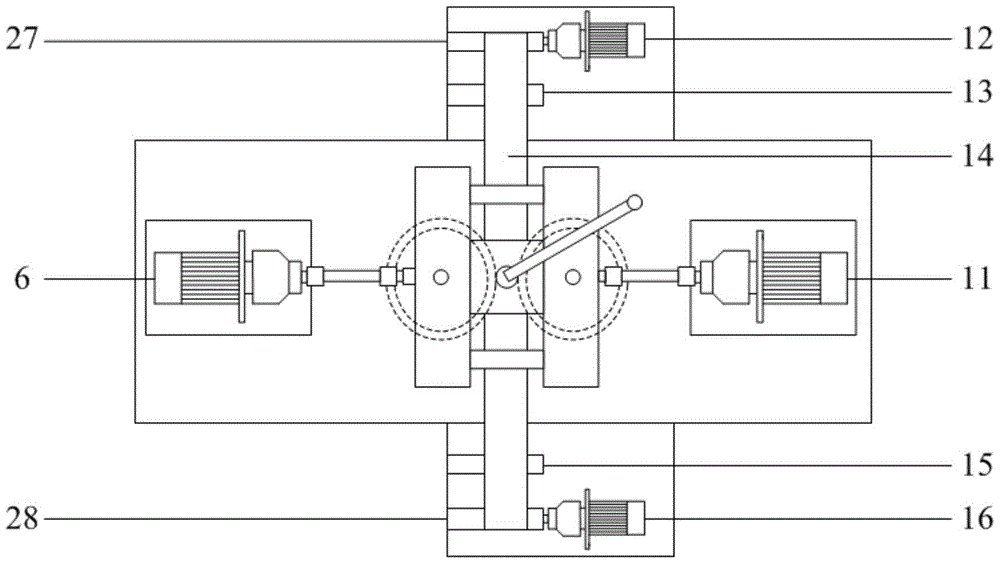

[0029] In this embodiment, the rolled piece 14 is a red copper strip, the initial thickness of the rolled piece 14 is 500 μm, the width is 80 mm, and the rolling target thickness of the rolled piece 14 is 2 μm. At the same time, it is decided to adopt a 20-pass rolling plan, and after 20 passes The rolling stock 14 is rolled to the target thickness. Among them, the applied ultra-thin strip rolling mill is self-made equipment, such as Figure 1~4 As shown, it includes a rolling mill main control part and a rolling mill mechanical part 1, the rolling mill main control part includes a main control computer 2, an operating console 3 and a PLC4, and the rolling mill mechanical part 1 includes a stand 5, a first main drive motor 6 , the second main drive motor 11, the upper work roll 23, the lower work roll 25, the upper support roll 22, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com