Domestic rubbish treatment system

A treatment system and technology for domestic waste, applied in the direction of solid waste removal, etc., can solve the problem that waste incineration power generation does not conform to the general environment, and achieve the effect of improving drying effect, reducing use cost, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

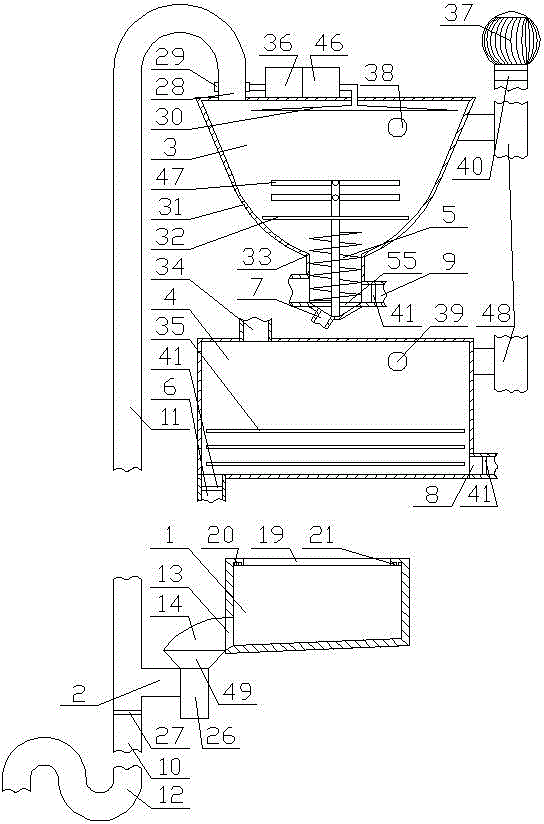

[0102] Such as figure 1 As shown, it includes a hopper 49 communicated with the feed port A of the crushing device 26, and the discharge port A of the crushing device 26 communicates with the feed port B28 provided on the upper part of the fermentation chamber 3 through a raw material conveying device. The discharge port B33 provided at the bottom of the chamber 3 communicates with the feed port C34 provided at the top of the drying chamber 4 through the decomposed clinker conveying device 5. The bottom of the drying chamber 4 is provided with a discharge port C6, and the fermentation chamber 3 and The top of drying chamber 4 is respectively provided with air vent A38 and air vent B39, and described air vent A38 and air vent B39 communicate with air pipe 48 respectively, and the top of described air pipe 48 is provided with draft device, and described air vent A38 and Vent B39 is provided with filtering device A respectively; Fermentation material stirring device 47 is arrange...

Embodiment 2

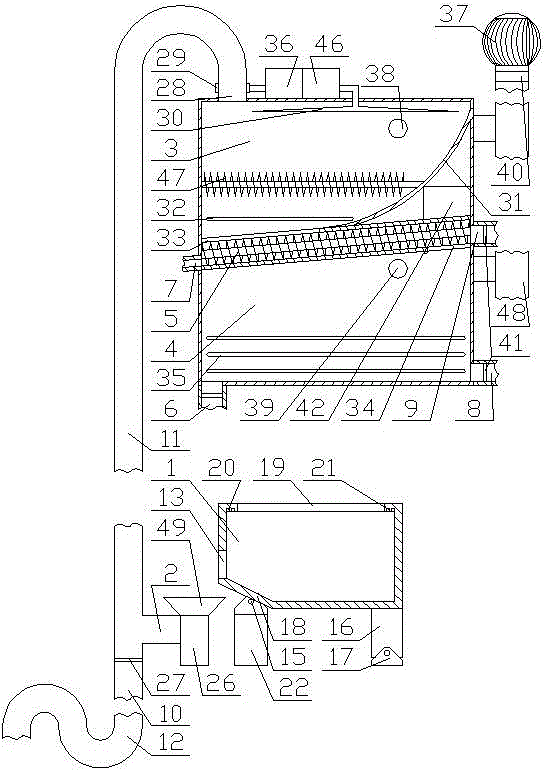

[0139] Such as figure 2 As shown, it includes a hopper 49 communicated with the feed port A of the crushing device 26, and the discharge port A of the crushing device 26 communicates with the feed port B28 provided on the upper part of the fermentation chamber 3 through a raw material conveying device. The discharge port B33 provided at the bottom of the chamber 3 communicates with the feed port C34 provided at the top of the drying chamber 4 through the decomposed clinker conveying device 5. The bottom of the drying chamber 4 is provided with a discharge port C6, and the fermentation chamber 3 and The top of drying chamber 4 is respectively provided with air vent A38 and air vent B39, and described air vent A38 and air vent B39 communicate with air pipe 48 respectively, and the top of described air pipe 48 is provided with draft device, and described air vent A38 and Vent B39 is provided with filtering device A respectively; Fermentation material stirring device 47 is arrang...

Embodiment 3

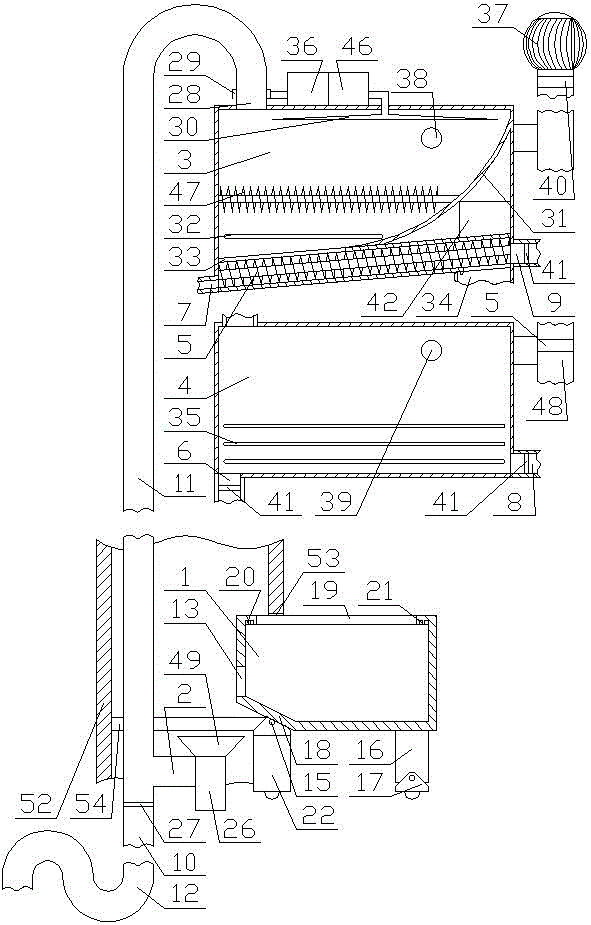

[0177] Such as image 3 As shown, it includes a hopper 49 communicated with the feed port A of the crushing device 26, and the discharge port A of the crushing device 26 communicates with the feed port B28 provided on the upper part of the fermentation chamber 3 through a raw material conveying device. The discharge port B33 provided at the bottom of the chamber 3 communicates with the feed port C34 provided at the top of the drying chamber 4 through the decomposed clinker conveying device 5. The bottom of the drying chamber 4 is provided with a discharge port C6, and the fermentation chamber 3 and The top of drying chamber 4 is respectively provided with air vent A38 and air vent B39, and described air vent A38 and air vent B39 communicate with air pipe 48 respectively, and the top of described air pipe 48 is provided with draft device, and described air vent A38 and Vent B39 is provided with filtering device A respectively; Fermentation material stirring device 47 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com