Glass bottle glazing tooling online cleaning device

A technology for cleaning devices and glass bottles, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of hidden quality problems, difficult insertion and removal of spray glaze products, etc., and achieve extended use The effect of reducing time, eliminating quality hazards, and reducing input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

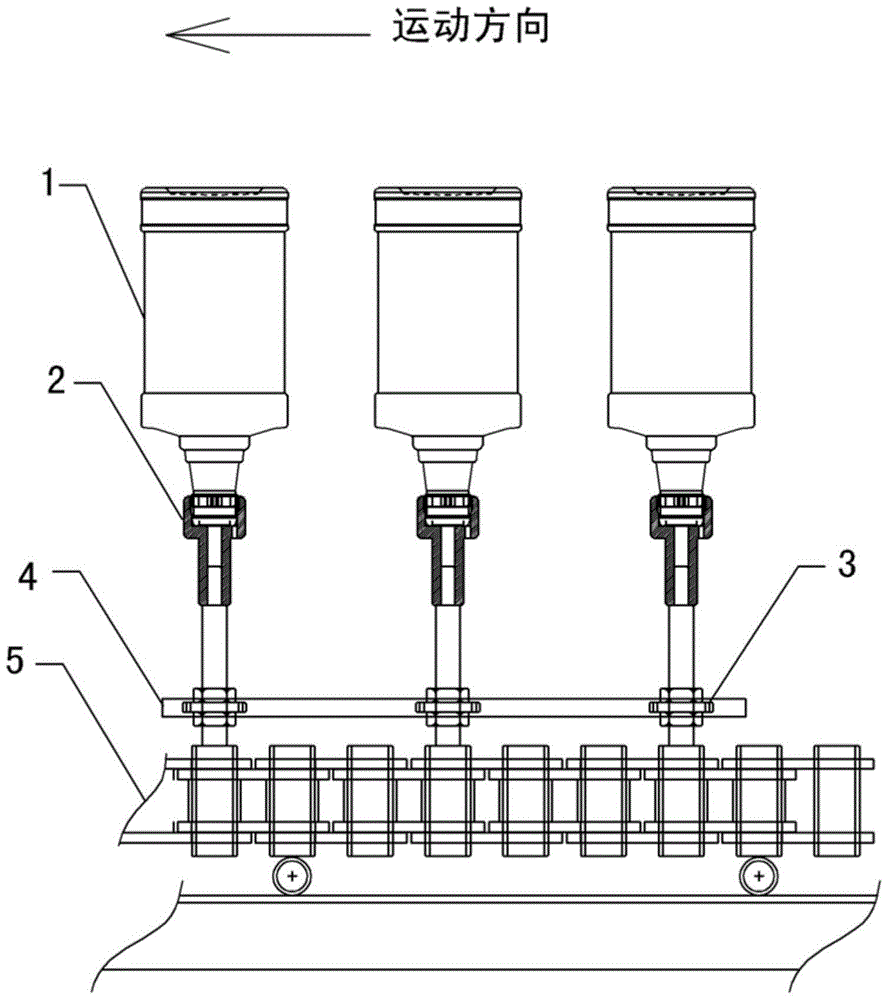

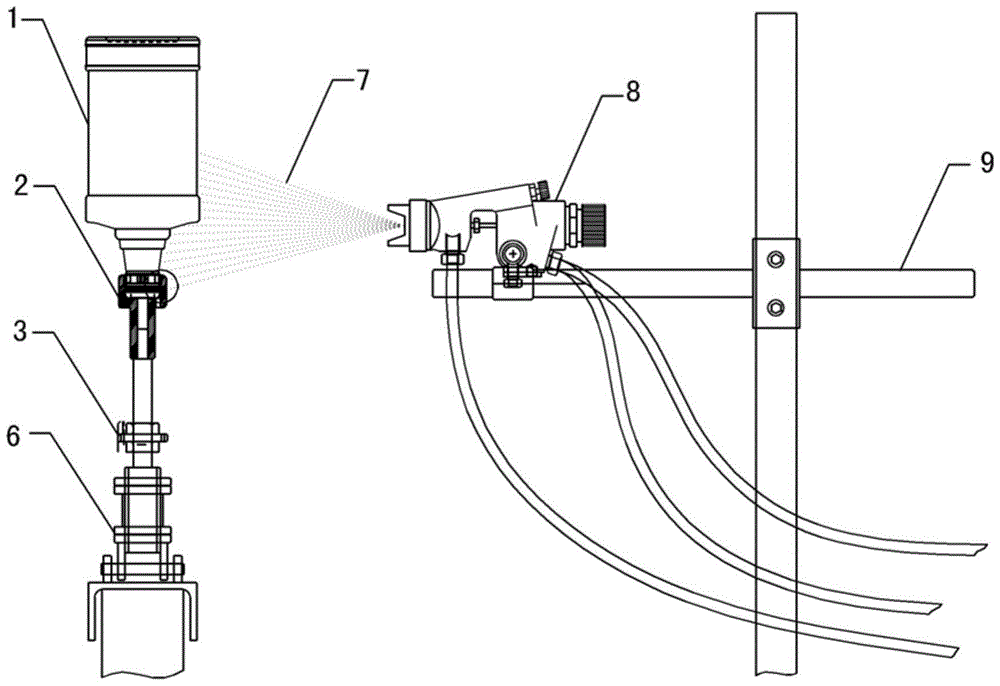

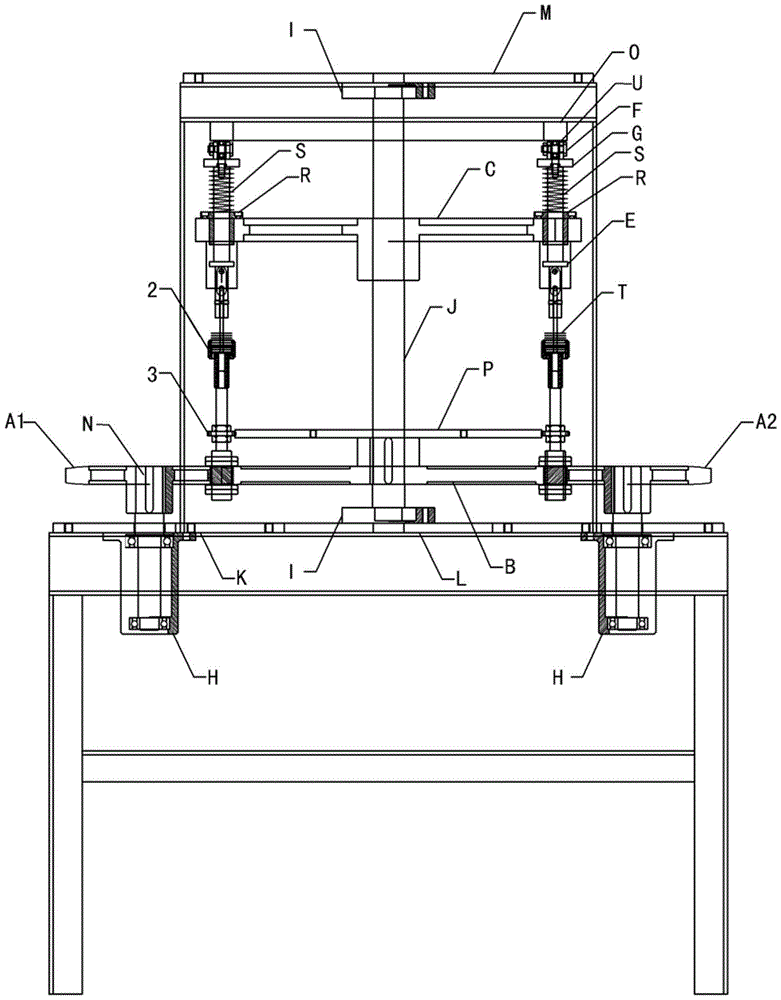

[0043] In this embodiment, a glass bottle glazing tooling online cleaning device is applied in a glass bottle glazing production line, such as Figure 1a with 1b As shown, on the central axis of every two pitches of the main transmission chain 5, a forced rotation sprocket 3 and a glaze spray tooling 2 are arranged. Because the pitch of each chain 5 is constant, every two adjacent The center distance of tooling 2 is also determined. When the glaze product 1 is spraying the glaze paint, the spray gun 8 is fixed, and the mouth of the spray product 1 is installed on the glaze spray tool 2, and the lower part of the tool 2 is a circular rod hole, and the forced rotation chain is inserted into the rod hole. In the iron round shaft on the upper part of the wheel 3, the glass bottle glazing production line is driven by the main drive chain 5 to drive the glazing product 1 set on the glazing tooling 2 to move in a straight line, and at the same time, the forced rotating chain 4 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com