Method for preparing Zn<2+> doped SnS2 nano-photocatalysis material Sn(1-x)ZnxS2 with microwave hydrothermal method

A technology of sn1-xznxs2 and microwave hydrothermal method, which is applied in the field of preparation of nano-photocatalytic materials, can solve the problems of not too high deposition rate, short preparation cycle, expensive equipment, etc., and achieve short preparation cycle, moderate conditions, and shape uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) SnCl 4 ·5H 2 Dissolve O in deionized water and prepare solution A with a concentration of 0.5mol / L, press n Sn :n Zn =16:1 Add a certain amount of zinc gluconate into solution A, stir until fully dissolved to obtain solution B, and simultaneously use 1mol / L of HCl or NH 4 ·H 2 O adjusts the pH of solution B to 1, NaS·9H 2 O was dissolved in deionized water to prepare a solution C with a concentration of 0.1 mol / L.

[0027] 2) Dilute the two solutions of B and C according to the element molar ratio n Sn :n S = 1.0:1.0 was mixed to obtain solution D, and magnetically stirred at 26°C for 5 minutes to form a uniform and stable mixed solution E.

[0028] 3) Put the E solution into a microwave hydrothermal reaction kettle, seal the hydrothermal reaction kettle, control the volume filling ratio to 50%, control the reaction temperature at 120°C, and control the reaction time at 15 minutes, and react to obtain the precursor.

[0029] 4) After the reaction kettle was n...

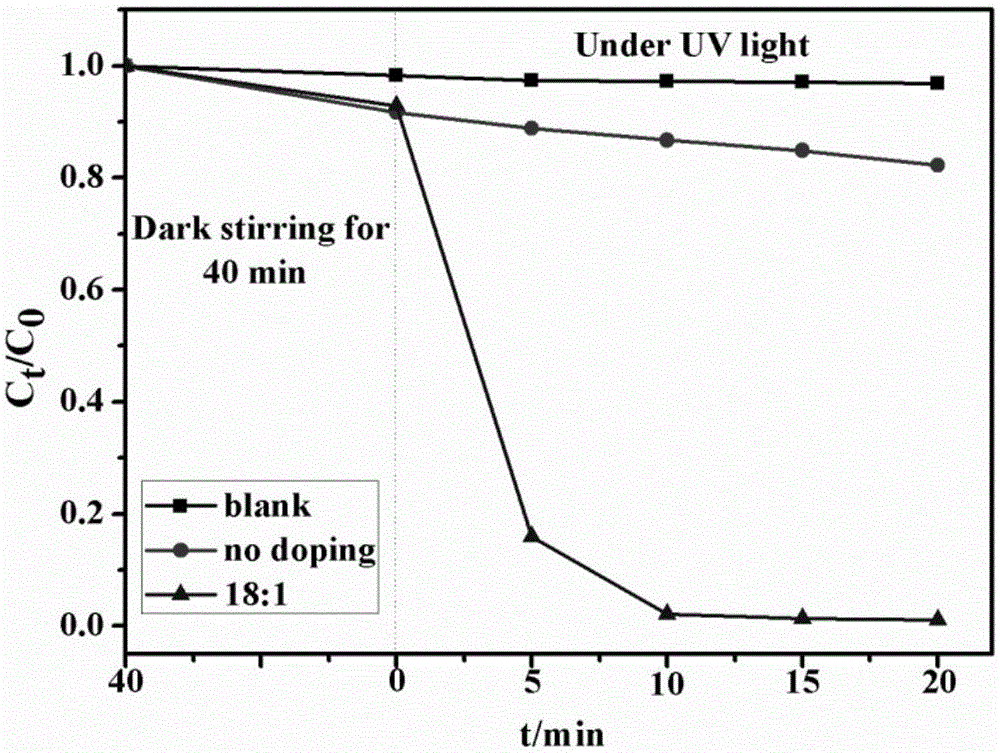

Embodiment 2

[0031] 1) SnCl 4 ·5H 2 O is dissolved in deionized water, and prepared as a solution A with a concentration of 0.8mol / L, press n Sn :n Zn =18:1 Add a certain amount of zinc gluconate into solution A, stir until fully dissolved to obtain solution B, and simultaneously use 1mol / L of HCl or NH 4 ·H 2O adjusts the pH of solution B to 7, NaS·9H 2 O was dissolved in deionized water to prepare solution C with a concentration of 1.5 mol / L.

[0032] 2) Dilute the two solutions of B and C according to the element molar ratio n Sn :n S = Mix at a ratio of 1.5:2 to obtain solution D, and magnetically stir at 26°C for 10 minutes to form a uniform and stable mixed solution E.

[0033] 3) Put the E solution into a microwave hydrothermal reaction kettle, seal the hydrothermal kettle, control the volume filling ratio to 60%, control the reaction temperature at 160° C., and control the reaction time at 30 minutes to obtain the precursor.

[0034] 4) After the reaction kettle was natural...

Embodiment 3

[0036] 1) SnCl 4 ·5H 2 O is dissolved in deionized water, and prepared as a solution A with a concentration of 1.2mol / L, press n Sn :n Zn =20:1 Add a certain amount of zinc gluconate into solution A, stir until fully dissolved to obtain solution B, and simultaneously use 1mol / L of HCl or NH 4 ·H 2 O adjusts the pH of solution B to 9, NaS·9H 2 O was dissolved in deionized water to prepare solution C with a concentration of 2.4mol / L.

[0037] 2) Dilute the two solutions of B and C according to the element molar ratio n Sn :n S =2.5:4.3 ratio mixed to obtain solution D, magnetically stirred at 26°C for 30min to form a uniform and stable mixed solution.

[0038] 3) Put the E solution into a microwave hydrothermal reaction kettle, seal the hydrothermal kettle, control the volume filling ratio to 60%, control the reaction temperature at 200°C, and control the reaction time at 90min to obtain the precursor.

[0039] 4) After the reaction kettle was naturally cooled to room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com