A kind of acetylene hydrochlorination reaction with low noble metal content au‑cu‑tio 2 The preparation method of /c catalyst

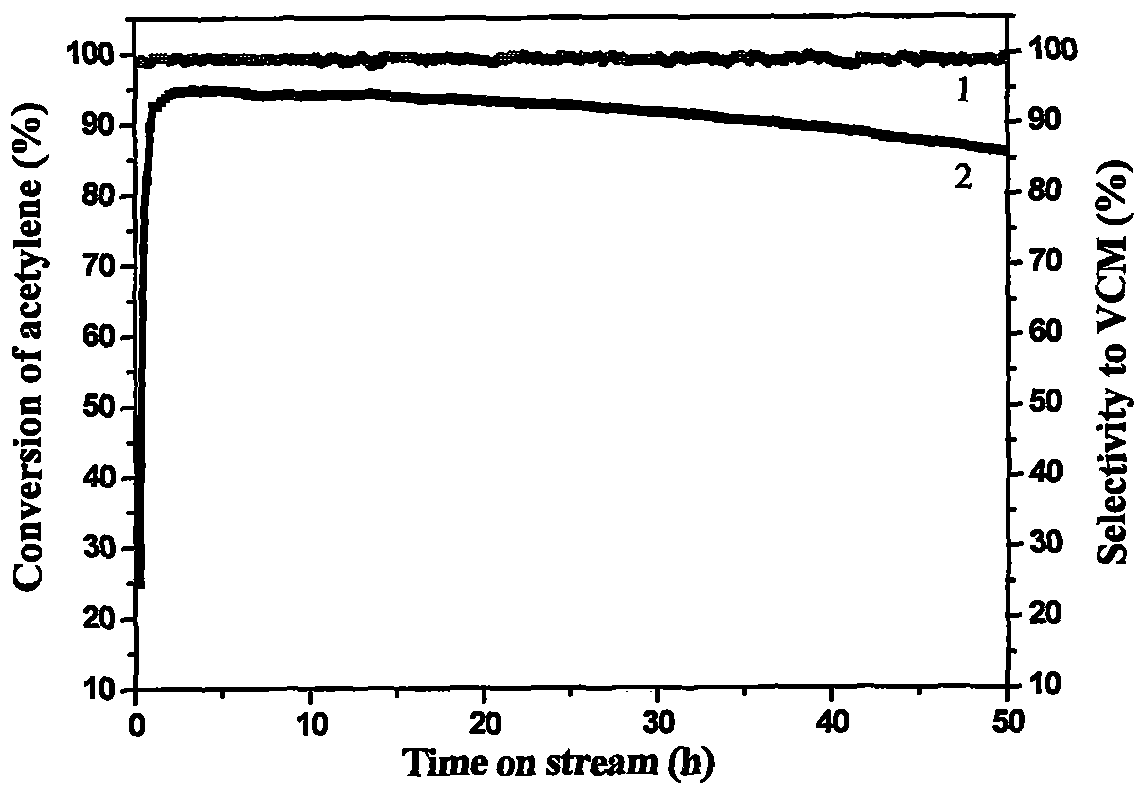

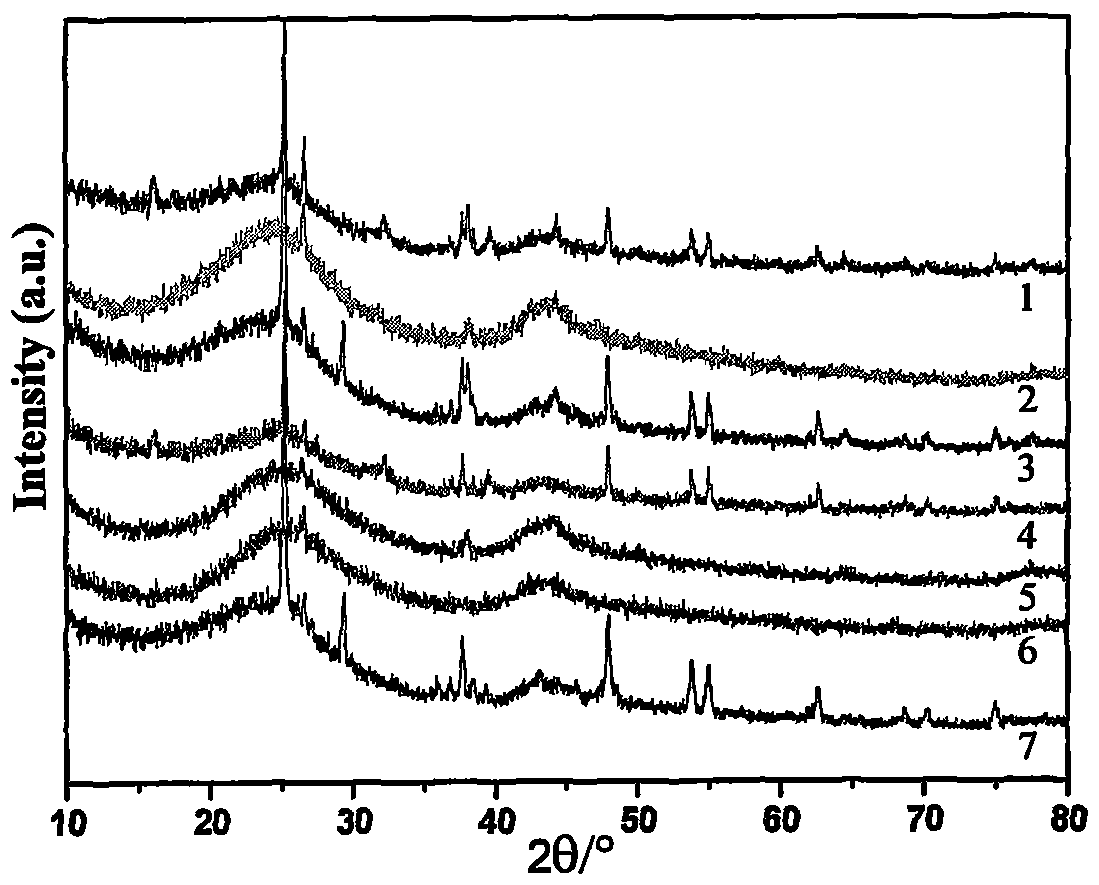

An acetylene hydrochlorination, au-cu-tio2 technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, hydrogen halide addition preparation, etc., can solve the problem of not significantly improving the catalyst. Au3+ stability, less research, deactivation and other issues, to achieve the effects of excellent catalytic activity, simple preparation method, and enhanced adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

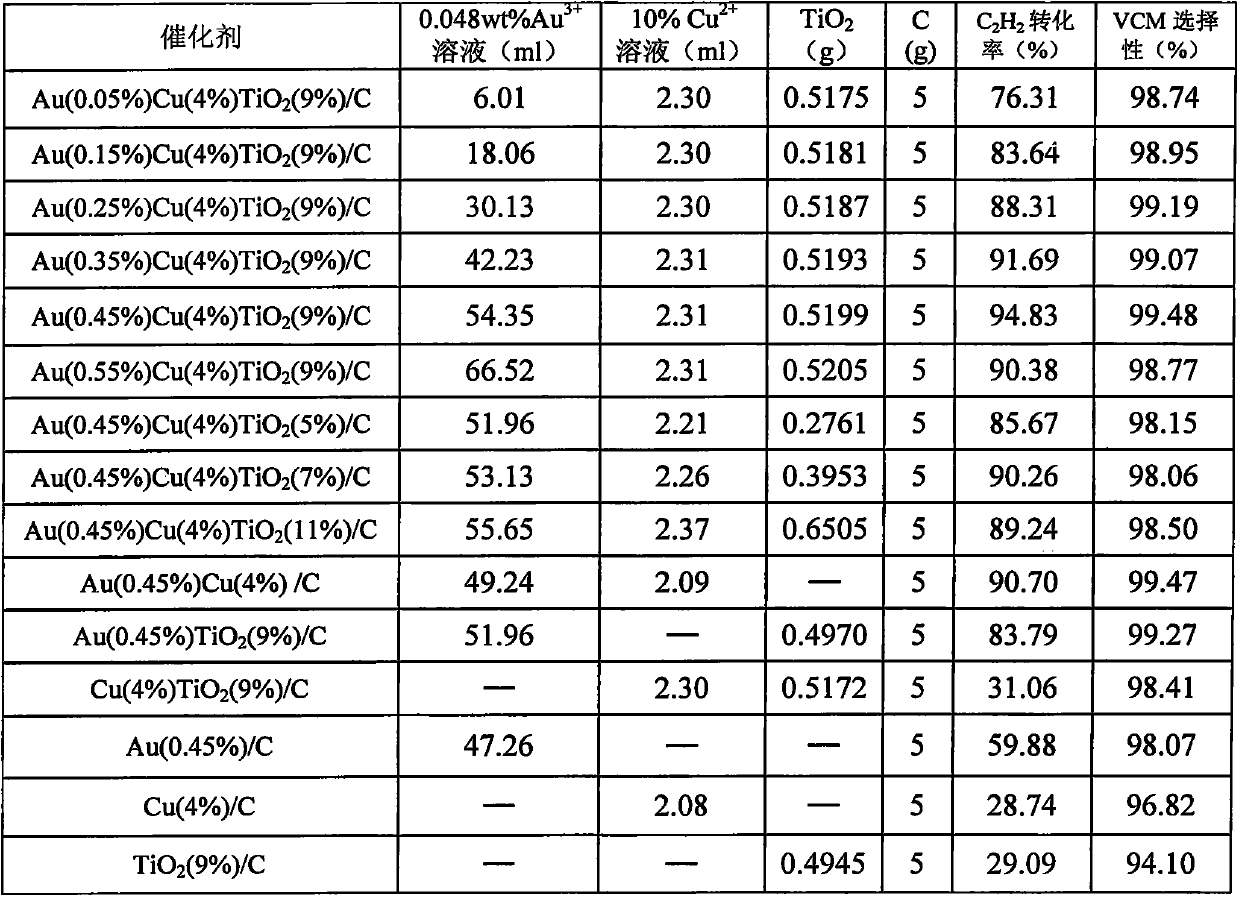

Embodiment 1

[0019] Activated carbon pretreatment method: Weigh a certain amount of granular activated carbon and add deionized water three times the volume of activated carbon to completely immerse the activated carbon in deionized water, stir on a magnetic stirrer for 1 hour, transfer to a centrifuge tube, and centrifuge in a centrifuge for 1 hour Finally, pour off the upper liquid, and then rinse it with deionized water five times to remove impurities therein, and finally dry it in an oven at 100° C. for 24 hours to obtain pretreated granular activated carbon.

[0020] Catalyst preparation process: first dissolve HAuCl with a certain amount of absolute ethanol 4 4H 2 O dubbed 0.048wt% Au 3+ HAuCl 4 4H 2 O ethanol solution, dissolve CuCl with a certain amount of absolute ethanol 2 2H 2 O formulated into 10wt% Cu 2+ CuCl 2 2H 2 O ethanol solution, take 54.35ml 0.048wt% Au 3+ HAuCl 4 4H 2 O ethanol solution and 2.31ml 10wt% Cu 2+ CuCl2 2H 2 O ethanol solution was mixed well, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com